3D printing is a rapidly growing technology that is being used in a variety of industries. Dentistry is one of the latest fields to adopt 3D printing technology, and it is revolutionizing the way dental appliances are made.

While 3D printing originally started as just printing models, it has now expanded to almost every aspect of dentistry and is being used to create actual dental appliances such as crowns, bridges, dentures, implant restorations and much more.

3D printing offers an attractive alternative to traditional milling of dental appliances. This most notably includes greater customization options, as 3D printing eliminates some of the limitations posed by 4-axis machines which can result in over-milling.

What is the Dental Assistants role in 3D printing ?

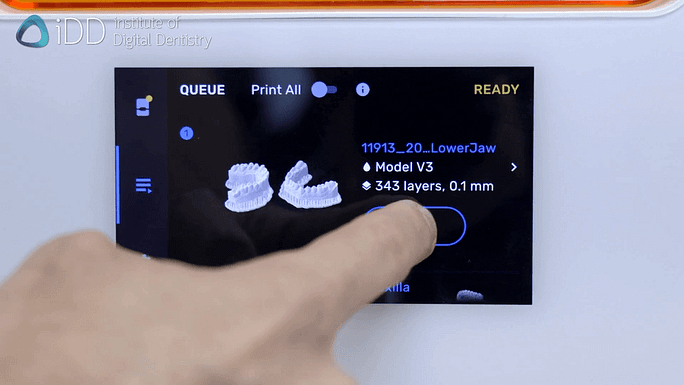

As with any medical field, dental assistants provide a vital support role to ensure successful patient treatment using 3D printing. Dental assistants are responsible for preparing the 3D models for the printer and for loading the 3D software and data into the 3D printer.

This includes preparing the CAD files, selecting appropriate materials, and loading the data into the printer. Once the 3D printer is set up, dental assistants are also responsible for monitoring the process to ensure that the materials have been properly prepared, and that the 3D printer is working properly. They will also be responsible for preparing and cleaning the 3D-printed dental appliances once they are printed.

Dentists are quickly realizing that dental assistants can be trained to take over many tasks. These tasks include:

- Intraoral scanning

- Moving digital files

- Design

- Fabrication

- Printing

- Post-processing

And more!

The reality is that dental assistants across countries and states are poised to do more than what was traditionally thought possible. With the right qualifications and adequate training, dental assistants can offer services previously not part of their scope.

With the ever-changing landscape of technology, dental assistants must be up to date with the latest advances. This means taking the time to learn how to use new products, software, and equipment.

By understanding and having clear expectations of the roles of each team member and how to communicate effectively, dental assistants can help ensure that everyone is working together to provide the best possible patient care.

Training on how to work together as a team is essential for the full integration of 3D printing in the dental setting. By understanding the roles of each team member and how to communicate effectively, dental assistants can help ensure that everyone is working together to provide the best possible patient care.

With all these skills, dental assistants are essential to the success of any dental office. They help to ensure the best patient care, while also assisting the dentist in staying up to date with the latest technology.

Finally, dental assistants are also responsible for providing patient care, such as taking X-rays, cleaning dentures and teeth, and providing patient education. The combination of these tasks all helps to ensure successful patient treatment and the efficient use of 3D printing technology.

How Dental Assistants can help with 3D printing

Dental assistants have become essential players in the field of 3D printing. Dental assistants are in a unique position to use their expertise to assist with the data collection, design, and production of 3D printed dental prosthetics, printed fillings and crowns, and more.

With their knowledge of dental anatomy, materials, patient expectations, and organization skills, dental assistants can provide crucial insight when it comes to 3D printing dental products. The role of dental assistants in 3D printing has become increasingly important over the last few years, as they monitor lab case management, perform machine maintenance, and more.

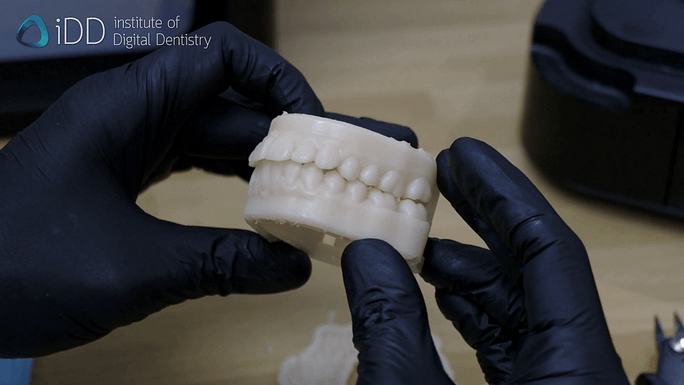

Furthermore, dental assistants can be responsible for the post-processing of 3D printed products, including the removal of supports, final polishing, and delivery of appliances.

Perhaps most importantly, dental assistants also play an essential role in the patient education process. They need to explain to patients what 3D printing is, why it is beneficial, and the potential risks associated with the process. By educating patients, dental assistants help to ensure patient safety and satisfaction, which is paramount in the dental profession.

The Benefits of 3D Printing for Dentistry

3D printing in dentistry can create high-accuracy, custom-made prostheses and dental appliances in less time and at a lower cost. This technology can drastically reduce the need for traditional dental lab work and labor.

3D printing also improves the patient's experience by allowing them to see their prostheses virtually, before they are manufactured. This helps ensure that the prostheses meet the patient’s needs, as well as their expectations. 3D printing even helps to reduce wait times for dental appliances, as they can be made quickly and effectively, oftentimes while the patient is waiting in the chair.

3D printing technology can produce a wide range of dental products, from crowns, bridges, dentures and indirect bonding trays and clear aligners.

Additionally, 3D printing can create a variety of materials, including flexible occlusal guards, flexible denture and partial bases, and ceramics, that are suitable for use in the mouth.

By using 3D printing, dentists can reduce the amount of time they spend on restorative procedures, as the technology allows them to quickly and accurately fabricate dental products.

Furthermore, 3D printing results in less waste, as the products are produced in the exact amount needed, and it also enables dentists to reduce their costs, as they do not need to purchase prefabricated equipment.

3D printing also allows dentists to offer their patients more aesthetically pleasing products, as the technology can create products with smoother surfaces and more accurate shapes. 3D printing has truly revolutionized the dental industry, and its benefits are far-reaching.

The Challenges of 3D Printing for Dentistry

While 3D printing technology can provide dentists with significant advantages in terms of speed and cost savings, there are a few challenges that need to be addressed.

For instance, 3D printing can be complex and require a lot of time and effort to perfect. Dental assistants need to be both knowledgeable in the equipment, materials and techniques needed for 3D printing and experienced in the dental technology field in order to ensure successful results. Time for training is a must, as well as forgiveness for mistakes while learning.

3D printing is still a relatively new technology, and there is still a lack of standardized guidelines and protocols for using it in a dental setting.

This can lead to inconsistencies in the quality of the products produced, as well as the safety of the product for use in the mouth. Following manufacturer guidelines is an absolute must, as well as keeping up to date on current research.

By learning more about 3D printing, dentists and dental assistants can help create an improved workflow that reduces costs and improves patient safety while still utilizing the advantages of 3D printing technology.

The Future of Dental Assistants and 3D Printing

The future of dental assistants and 3D printing is a bright one as more advances and training in 3D printing technology continue to be made. Dental assistants are able to remove some job duties such as pouring up and trimming models, while gaining other responsibilities like lab case management, digital design, and more.

Many dental assistants report increases job-fulfilment as well as increased wages for learning and implementing such technology.

As 3D printing becomes more widely popular in dentistry, dental assistants who have expertise in 3D printing will be even more in demand due to their skill set. They will be able to train other members of the dental team on proper use and operation of the 3D printing machines. Additionally, their knowledge of the available materials, techniques, and software that make up 3D printing will be essential to its successful implementation.

The rise of 3D printing in dentistry is offering a wide variety of opportunities for dental assistants, particularly the ability to rise to be a leader and teach others. From teaching the team members how to properly use the technology, to understanding the materials and software that make up the process, dental assistants are playing an increasingly important role in the dental industry.