3D Printing technology (also known as additive manufacturing), is making its way into every industry imaginable and dentistry is no exception. If you’re considering implementing 3D printers into your dental practice or laboratory, this article is for you. Learn everything you need to know about the different types of 3D printers that exist and what may be the best choice for you to invest in.

Modern 3D Printing Technology

CAD/CAM technologies have been proven to be a great tool in dentistry, both chairside and in dental laboratories. Computer-aided manufacturing (CAM) has mostly relied on CNC milling machines until recently. 3D printing now can be used for a large range of different applications in dentistry including, but not limited to:

Before purchasing a 3D printer, it is important to ask yourself some questions. What do you want to use a 3D printer for? Do you have the right technology? At the minimum you will need a desktop or intraoral scanner and preferably a CBCT machine (or access to one). Within what timeframe do you require prints? Cheaper printers tend to take around 6-7 hours for a model while more expensive printers can do this within 20 minutes.

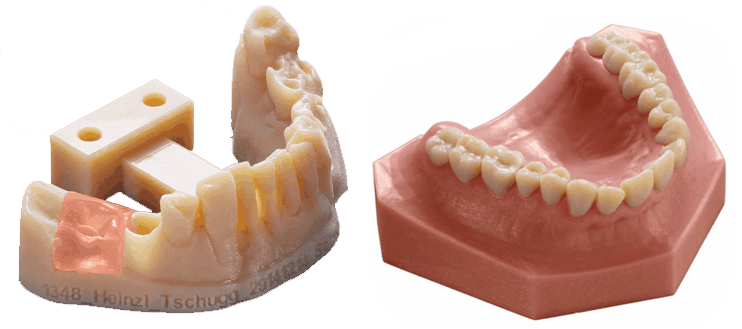

Some 3D printing examples: full arch model, night guard and surgical guide printed in-house.

Dentures, orthodontic appliances, temporary restorations and frameworks are also possible.

Ever since key patents of 3D printing technology expired in 2013, the market has been flooded with companies trying to find their place in this growing industry, which has seen significant developments in technology becoming available to consumers at increasingly competitive prices. In current times, there is a huge range of different printers available on the market, including inexpensive printers like the Anycubic Photon, to mid-range printers like the Formlabs Form 3 or Sprintray Pro. There are also are more industrial printers such as the Nextdent 5100 or Asiga Max.

In our dental clinics we have been using 3D printers for the past 5 years and found them to be extremely useful. Although there is often a bottleneck effect due to the printing time, 3D printing has opened up a range of different treatment modalities for us that were not as easily accessible in the past.

There has been large amounts of research in this field and several technologies have been developed by companies trying to find their edge. As a result we have a large number of different terms now for basically the same technology - for example, what Stratasys calls PolyJet is MultiJet for 3D Systems, but both are essentially the same material jetting technology. At its core, the definition of 3D printing is “the process of joining materials to make objects from 3D model data, usually layer upon layer” - American Society for Testing and Materials.

The term additive manufacturing includes many types of 3D printing technologies, this includes:

These technologies can also be sorted into seven different types of processes that describe how the layers are made and what materials can be processed this way. Note that not every process is suitable for every material:

The most commonly used technologies in dentistry are selective laser sintering (SLS), material jetting (MJ), stereolithography (SLA), and fused deposition modelling (FDM).

To address several queries about 3D printers from our readers and subscribers, we will now explain each one of these technologies, including their individual strengths and weaknesses.

Selective Laser Sintering - SLS

Selective laser sintering or SLS, can include multiple techniques, like selective laser melting (SLM) or direct metal laser sintering (DMLS). These all share the same principles but are branded differently for patenting reasons and often vary slightly. SLS is often reserved for the processing of ceramics and nylons, while SLM is mostly for metal alloys. An example of a SLS 3D printer is the Fuse 1 - a small benchtop model from Formlabs.

The name of this technology is self-explanatory: a laser targets loose, powdered material (e.g. metal) which sinters or ‘melts’ it into the pre-programmed shape. This type of 3D printing is also called powder bed fusion because it uses a bed of powder to support the design and no additional supports are necessary, which keeps the post-processing minimal.

This process used to result in a porous and fragile product but this has been improved by using a vacuum and other advancements. Nowadays, the final products are much denser and stronger and also very accurate (50 - 100 µm). This makes them great for processing metal frameworks such as CoCr or titanium, which are notorious for putting strain on milling machines and burs.

Material Jetting - MJ

Material jetting (MJ) is a type of 3D printing called inkjet or polyjet by some companies. Although there might be slight differences between the respective machines, they again share the core principle - liquid material gets jetted onto the platform where it is subsequently solidified with UV light before another layer is deposited. Due to the nature of this mechanism, only materials that can be liquefied can be processed this way, namely plastics and polymers.

Some machines have multiple nozzles which can be connected to multiple tanks – this allows the use of various materials which make MJ 3D printers potentially useful for printing dentures. Their very high accuracy (20 - 85 µm) makes them also suitable for printing models, orthodontic appliances and surgical guides. There are currently dental-specific 3D printers available, like the Objet30 OrthoDesk by Stratasys which is specifically designed for orthodontic labs and clinics.

An example of models printed using a material jetting 3D printer. The advantage of these is the capability of printing using various materials simultaneously.

In this case, a model with removable soft tissue (left) and a model with a pink-coloured material for the tissue and base and a more natural-looking material for the teeth (right).

Stereolithography - SLA

Stereolithography, or SLA for short, is another very popular form of 3D printing used in dentistry. It is also one of the oldest methods of additive manufacturing. There have been significant advancements in this technology in recent years, as mask stereolithography (MSLA) and digital light processing (DLP) have been introduced. This has become one of the most popular types of 3D printers for use in the dental industry, with various companies introducing dental-specific machines, such as Whip Mix and their Asiga printers, Kulzer’s Cara Print and the Form 2 printer by Formlabs.

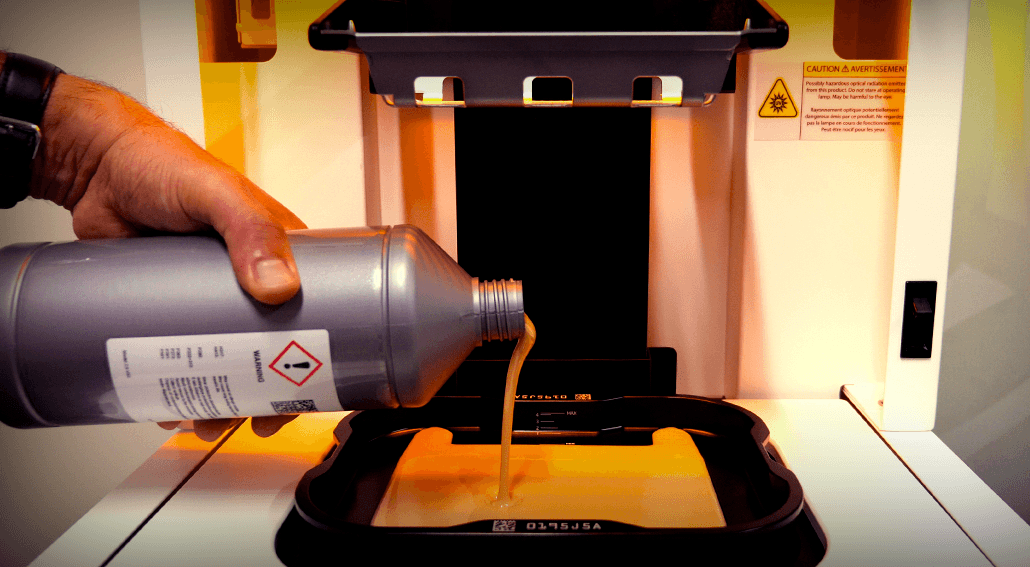

These printers use vat polymerisation or photopolymerisation principles: thin increments of photosensitive liquid material in a vat are cured with UV light until a whole layer is formed. The platform then moves away from the vat vertically, thus making room for another layer. These layers then adhere to each other due to the self-adhesive property of the polymer.

A night guard attached to the build platform. Printing using a DLP 3D Printer by NextDent.

The biggest difference between SLA and DLP is the formation of these layers. Classic SLA printers would form the layer point by point, while DLP printers form a whole layer at once, which reduces the printing time significantly. These printers also provide highly accurate results (40 - 100 µm).

The biggest disadvantage of this technology is a fairly small build platform which doesn’t allow the fabrication of multiple restorations, frameworks or models at once. The operator often needs to resort to vertical positioning or horizontal stacking. Both of these approaches require extra material for the supports and more time spent manually post-processing in order to remove remnants of these structures. You can also only print using one material at time, since the building platform is submerged into the material in the vat.

Fused Deposition Modelling - FDM

Fused deposition modelling or FDM for short, is a material extrusion type of 3D printing technology. Thermoplastic material comes on a coil in the form of strings and is pushed through a nozzle that heats up the material to its melting point. This nozzle moves over the platform below it and deposits the softer, melted material onto the platform, but only in certain places determined by the pre-programmed path of the nozzle. Once the layer is complete, this platform is lowered and a new layer is formed in the same fashion. Examples of FDM 3D printers include Ultimaker and Replicator+ printers by MakerBot.

Coils of thermoplastic material

Any material that comes as paste or can be safely turned into one can be processed in this way. In dentistry, this means polymers and plastic materials. Hobby machines can process ceramics too. Unfortunately dental ceramics don’t come in a paste form suitable for this process.

The FDM machine’s ability to use several materials simultaneously makes this technology potentially applicable in printing dentures and other removable prosthetics. Besides the multi-material build, the relatively cheap price of these machines and their materials makes them an attractive option. FDM 3D printing is also fairly accurate (200 - 500 µm), although nowhere close to the previously described types or 3D printers.

As with any material that requires cooling, warpage may result, similar to zirconia or casted metal frameworks. This has proved to be unsuitable in particular for printing dental models. So although FDM is a very popular 3D printing technology overall, it hasn’t really found a reliable application in dentistry and companies focusing on 3D printing for dental professionals seem to be shying away from it.

If you’re interested in learning more about 3D Printing and its dental applications,

click here to view our online courses.

Conclusion

There are many dental-specific 3D printers available on the market these days and there tends to be confusion due to the fact that companies brand similar technologies differently for either marketing or patent reasons. To summarise, the most popular 3D printers for dental offices and laboratories utilize either selective laser sintering (SLS), material jetting (MJ, polyjet, inkjet) or stereolithography (SLA, DLP) technology.

These are all comparable in terms of printing accuracy, with material jetting machines often exhibiting the highest accuracy. The low printing accuracy is one of the key reasons why printers using fused deposition modelling (FDM, FFF) fail to find popularity in dental applications, despite their popularity in other fields and relatively low cost.

Additive manufacturing works great with polymers and plastics and even with processing various metal alloys that might be otherwise difficult for milling machines to process. Unfortunately, dental ceramics still remain a very tricky material to be processed in this way.

Nice post Thanks for your information