During our trip to Cologne for IDS 2023, we had the chance to stop in at vhf’s booth. I was super excited, as they are one of the leading manufacturers of amazing chairside milling machines.

At IDS 2023, vhf released three new products. One I was really excited about - a machine that trims aligners.

I spoke with vhf's Chief Stratergy Officer Nicolas Rohde to speak about their new releases.

You can watch the full video - with a demonstration included - or read the transcript below.

Thanks a lot for talking with us Nicolas, can you tell us about vhf’s new release?

Thank you so much for visiting our booth! We are very, very excited about this new release. We launched this product just yesterday. It's an aligner trimming machine. It trims thermoformed aligners, bite guards, sports guards, night guards.

Interesting! I’ve found that the aligner and orthodontic market is blowing up - but we don’t have a great solution for manufacturing aligners in-house. There’s printing which is kind of working… and kind of not. And thermoforming but trimming thermoformed aligners is a lot of labor. These kinds of products really bridge the gap for dentists to be able to do high volume in-house.

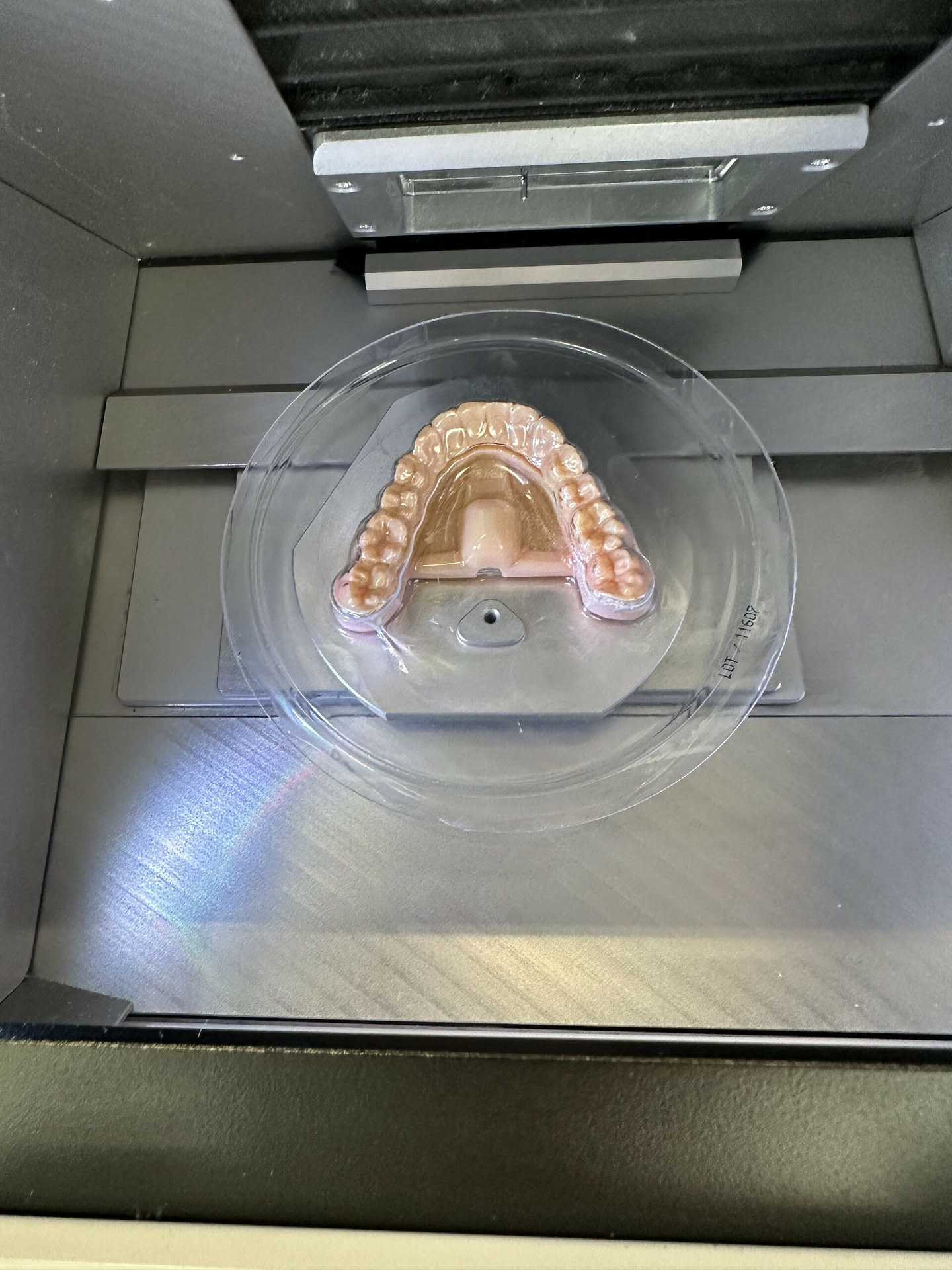

Yeah, absolutely. It's a very tedious and repetitive part of the workflow of traditional aligner manufacturing. And this makes life here a lot easier. We have our own trim CAM software developed for it, that automatically detects the trim line of the aligner, and it's a complete open system. You can use any intraoral scanner, or you can use any Ortho planning software or Ortho planning service with it. You just import the STL to our software. It automatically merges the model file with our connection here to the machine. You just insert the model without any tools. And then from there you just close the machine and press start.

Can you talk us through the process?

It takes literally less than one minute to trim an aligner. After referencing the axis, the tool will come from the top. It's one tool and then it will just follow the trim line that has previously been determined by the CAM software. And you see how the tool actually goes around the trim line. So for this case, it takes about 40 to 45 seconds and you have a very, nice margin line.

Sounds great! Can you tell us about one of your other releases - the E4 Chairside Milling Machine?

Sure! It's the second machine in our new E series and the goal was to have a milling machine for the chairside application that is super easy for dentists to use, install, operate and maintain it.

It’s really lightweight at just 28 kilos. So it can be shipped, basically overnight, from a reseller to a customer. Also, if there should be any issues in the future, it can be easily replaced. It is a wet and dry milling machine. It does not require any compressed air, which is a big plus for a dental office. And it still mills at the same premium quality that people expect from vhf.

28 Kilos? That’s crazy! Can you tell us a bit about how it operated?

So on the chairside version, it comes with a tablet with a customized version of our dental CAM software. We also manufacture our milling tools for single block. Again, it's wet and dry. You have the wet standard operation, and then if you opt to do it, you can upgrade to a dry milling kit and again - no compressed air. Because we have something very exciting here, which is called an air tool, which is a technology, that basically generates the compressed air in the machine. A rotor that is permanently fixed on the milling tool. With the velocity of the spindle and the tool, it keeps all the dust away from the block.

And I understand that's a patented technology?

Correct. Patent pending.

What's the mandrel? Is it just the standard, CEREC mandrel that people are used to?

Correct. We have the standard CEREC mandrel and we pride ourselves on being a hundred percent open to any CAD software, but also to any material. So pretty much any material that is on the market with this mandrel, can be used in our CAM software and with this machine.

That's everything about the E4 in a nutshell.. The newest chairside mill by vhf. Really, what's most impressive is that vhf is pricing this under 20,000 USD. You heard that correct. At that sort of price, it's really making chairside milling almost a no brainer.

What are your thoughts? Leave your comments below!