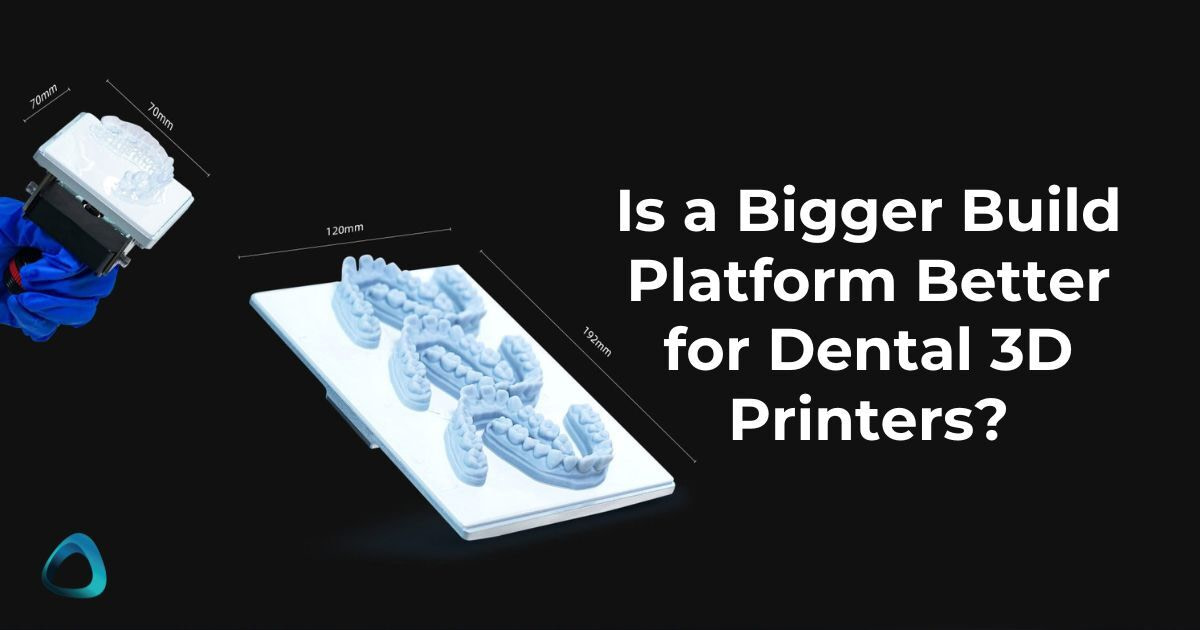

When considering a 3D printer in dentistry, it’s understandable to think that bigger is better, well at least for the build platform - but that’s not always the case.

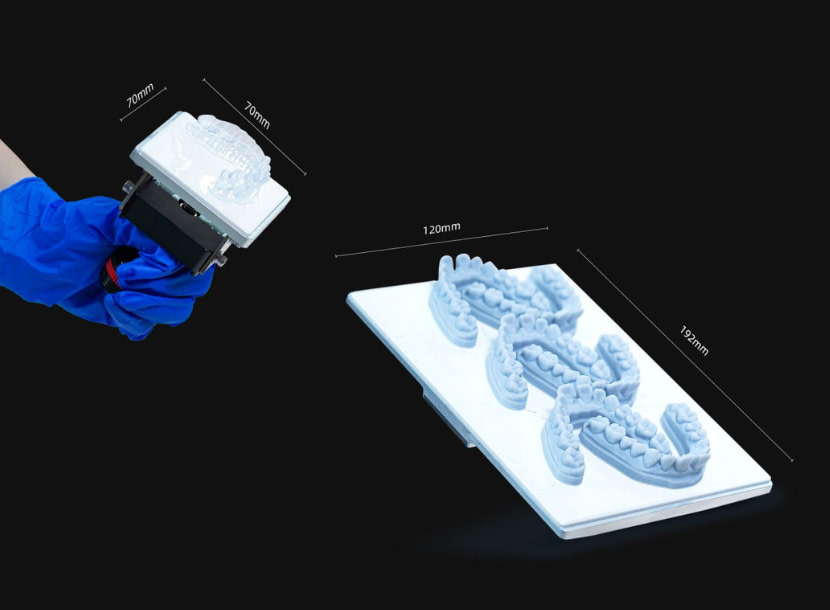

Of course, with a larger 3D printing build platform you’d be able to print a larger amount of dental applications in each print, but there are many advantages of having a smaller build platform, especially if you are considering chairside 3D printing.

Just recently for example, Shining 3D has added a new smaller build platform into their portfolio for their printers. This is something that was started by Ackuretta and then continued by SprintRay with their Crown Kit and Arch Platforms.

So, I thought I’d explain the differences between large and small build platforms, their benefits and what dental professionals should opt for.

Enjoy!

Why a smaller build platform for your 3D printer can be a good thing

In 3D dental printing, the dimensions of the build platform and vat play a crucial role in determining the efficiency and speed of the printing process.

A smaller vat means a smaller printing area, which results in reduced peeling forces.

What are peeling forces in 3D Printing?

In simple terms, as your printer is printing layer by layer, it has to move the build platform up. Resins are sticky, viscous fluids. So there is a force that is applied to the build platform as it pulls up each layer.

Lower peeling forces allow faster and easier movement of the motors that control the vertical motion of the build platform. As a result, these motors can move up and down more swiftly, enhancing the overall speed of the printing operation.

Although you would think this force is negligible. Yes, this peeling force has been proven to be extremely important for print speeds. It's part of the reason why smaller build platforms are recommended when printing small applications like crowns.

Additionally, with a smaller printing area, the lifting distance required for the release of the print film, such as nFEP or similar material, to adequately release the prints is lessened.

This means that the time taken for each layer to detach and for the next layer to start printing is reduced, leading to faster printing times.

Surprisingly, small platform 3D printers aren’t all that common. Currently only Ackuretta and SprintRay have these printers in their portfolios - with Shining 3D now joining them.

As 3D printers continue to develop, and in light of this huge wave of chairside 3D printing happening, we expect to see more and more of these smaller build platforms. Especially for chairside dentistry.

The downsides of a smaller build platform for your 3D printer

Now, obviously, there are downsides to having a smaller build platform. Mainly, you can’t print as many things on that platform when compared to bigger build platforms.

But, does that even matter? Do you really need a big build platform? And the answer to that is, it depends what you are printing. For labs that will likely be printing hundreds of models per week, yes it matters greatly. They need a big build platform for large volume prints.

However, for most dental clinics and dentists, a smaller build platform isn’t too much of a concern - especially if you’re mainly considering printing crowns, restorations, splints, and a model here and there.

As with all printing, you need to consider the printing technology itself. Some printers may not have the high precision mechanics or the advanced features of more expensive models. This can lead to lower-resolution prints, where fine details are not as sharp or accurate.

It’s also important to consider that some printers might have restrictions on the types of materials they can use, limiting the range of indications you can print.

Hence why open printers are likely going to be the most popular in the market as they are compatible with many resins, especially more advanced materials that are being developed for long-term restorations.

If you are a lab or print a large volume of work daily, a smaller build platform won’t be as efficient. The need to produce parts in several smaller batches rather than a few larger ones can significantly slow down production times and increase labour. And in that case, you may considering investing in multiple systems.

Should you opt for a smaller 3D printer - or a large one?

Deciding on what size build platform you should opt for generally depends on what you want to do with it.

If you’re a dentist working in a clinic, looking to print things like surgical guides and splints on a case-by-case basis, a smaller build platform could be a good idea. Especially if you are interested in printing crowns and bridges.

It’s faster, and you will potentially be able to provide same-day dentistry for your patients - which, let’s face it, is becoming more popular with patients as surveys have shown.

If you’re a dental lab, I would recommend getting a larger build platform printer. While the speed benefits of a smaller printer are great, the sheer amount you’d need to print means that you need something that can hold up to the demands of a dental lab - so definitely opt for a printer with a larger build platform.

Thinking of buying a printer for your lab or clinic?

iDD has reviewed nearly every 3D printer on the market. Based on our own clinical use, we’ve reviewed every printer on things like speed, ease of use, investment cost - and more.