This three-part series originally appeared on Ivoclar’s website as a way to show dentists around the world how impactful digital technology can be to their daily dentistry. With Ivoclar’s permission, we have reposted the content here for you.

Digital dentistry has transformed our dental practices here in Wellington, New Zealand, and continues to revolutionize the field of dentistry.

For us, it has been a 20 year undertaking to transform our five dental clinics from the comfort zone of status-quo dentistry to a fully digital workflow.

Today, each one of our clinics is equipped with intraoral scanners, CAD/CAM equipment, and all the latest materials and technologies the profession offers.

Our Institute of Digital Dentistry offers the latest clinical and laboratory CAD/CAM equipment from intraoral scanners and laboratory scanners to photogrammetry devices, milling machines, and 3D printers.

Our laboratory at the Institute of Digital Dentistry, Naenae Dental Clinic, New Zealand.

In fact, we are so passionate about the possibilities of digital dentistry that we opened New Zealand’s first digital dentistry training center where like-minded dental professionals from around the globe gather for live and online courses.

After all, our mission at the Institute of Digital Dentistry is to ensure dental professionals gain the knowledge and confidence they need to use digital dentistry effectively and efficiently.

The knowledge and confidence we gained from our journey to achieve high-quality same-day restorations have completely changed how we practice dentistry and the perception of our patients on how dentistry is practised.

Our patients are “wowed” by our ability to provide them with single-visit restorations, which has become a significant selling point to families and friends and an enormously profitable and free marketing tool for our practice.

Digital dentistry allows us to create beautiful smiles in just one day.

Patients love the concept of leaving the practice with a new beautiful, life-like smile or, more simply, a same-day crown. No more temporaries; no waiting for weeks for the final restorations; and few, if any, final adjustments after seating (Figures 6-9).

This interdisciplinary full-mouth rehabilitation was performed on a patient with severe bruxism-related attrition. Prior to treatment, the patient underwent orthodontic treatment and multiple implant surgeries including a sinus lift.

Full-contour crowns were milled from IPS e.max CAD and fitted on a 3D-printed model prior to staining and glazing.

The final IPS e.max CAD restorations fired, stained, and glazed.

The patient at a 2-year recall. The IPS e.max CAD crowns were cemented using a resin adhesive, posterior implant-supported crowns followed.

Of course, our journey, like yours, is only possible with proven technologies and research-based materials that provide the combined trifecta of strength, aesthetics, and workflow efficiency. Over the years, we have placed more than 10,000 digitally-driven restorations, 90% of which were fabricated from a single all-ceramic material (IPS e.max®, Ivoclar).

Whether a single crown or a quadrant, we rely on materials that provide the highest quality aesthetics while maximizing our time, workflow efficiency, and profit, as well as the comfort and convenience of our patients.

For example, suppose we find decay mesial or distal to a crown preparation, which is quite common. In that case, we can simply prep the site, restore with an inlay or onlay milled from a complementary material (Tetric® CAD, Ivoclar), and bond both at the same appointment (Figures 10-15).

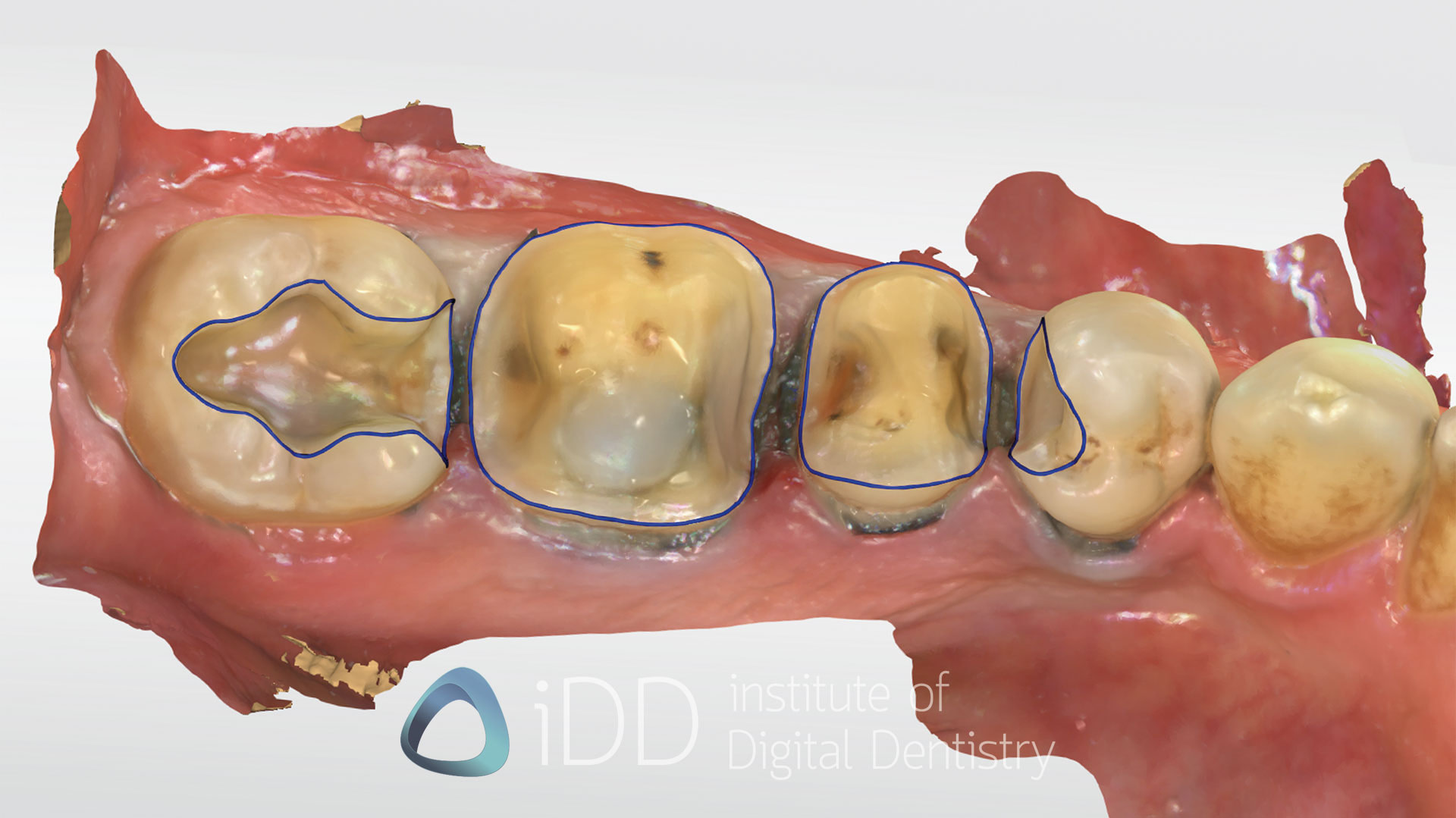

This same-day case involved restoring teeth #1-#3 with full-contour crowns and inlays. The patient was experiencing symptoms similar to cracked tooth syndrome.

During tooth preparation the amalgam fillings were removed, decay excavated, and compromised tooth structure reduced.

The preparations were scanned and margins delineated using CEREC Primescan.

The inlays and full contour crowns designed using CEREC Primescan.

The inlays were milled from a Tetric CAD block from Ivoclar Vivadent

Perfecting a digital workflow that is efficient, maximizes timesaving processes and increases profitability requires constant tweaking as the field of digital dentistry continues to evolve.

This immediate post-op image shows the final seated restorations cemented using resin adhesive cement.

The Tetric CAD inlays were polished and the IPS e.max CAD crowns stained, glazed, and crystallized for final esthetics.