The landscape of digital dentistry continues to evolve rapidly, with 3D printing technology playing an increasingly prominent role in dental practices and laboratories worldwide. As the adoption of additive manufacturing techniques grows, so does the focus on optimizing every step of the process - from initial design to final post-processing.

Post-curing, also known as post-processing, is a critical step in producing high-quality 3D-printed dental appliances. This process, which occurs after the initial printing and washing, aims to enhance the mechanical properties, biocompatibility, and overall quality of the printed object.

Various post-curing methods have been developed and refined over time, each with its advantages and considerations.

Traditionally, post-curing has been performed using UV light in the air, which can lead to certain limitations, such as oxygen inhibition on the print's surface. To address these challenges, alternative methods have emerged, including submersion in liquids like glycerin or water, using vacuum environments, and, more recently, nitrogen-rich atmospheres.

Each of these approaches aims to overcome specific hurdles in the post-curing process and produce superior results for dental applications.

Keep reading to find out more on each of these post-curing methods!

Download the Full Comprehensive Guide PDF

Download the full PDF to get a full copy of this article to read later.

Get a high resolution printable copy of this review.

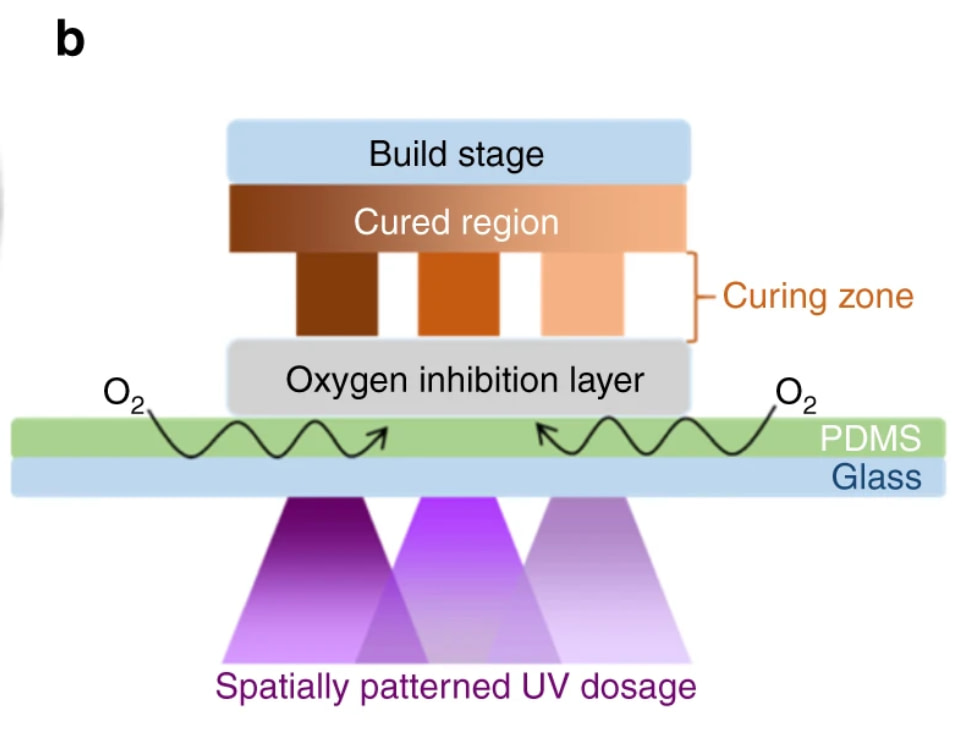

Understanding the Oxygen Inhibition Layer

The oxygen inhibition layer is a critical phenomenon in the 3D printing post-curing process, particularly relevant to UV-curable resins used in dental applications. Understanding this concept (and avoiding it) is essential for achieving optimal results in dental 3D printing.

At its core, the oxygen inhibition layer forms due to the interaction between atmospheric oxygen and the free radicals generated during the UV curing process. This interaction occurs primarily at the surface of the printed object, where the resin is in direct contact with air.

During curing, the following process typically occurs:

- UV light activates photoinitiators in the resin.

- These photoinitiators generate free radicals.

- The free radicals initiate a polymerization chain reaction, causing the resin to harden.

However, when oxygen is present, it can interfere with this process:

- Oxygen molecules react with the free radicals.

- This reaction forms peroxide compounds.

- These peroxides are less reactive than the original free radicals.

- As a result, the polymerization process is inhibited or slowed down.

Schematic of oxygen inhibition-assisted printing, in which the curing zone is physically limited between the cured region and the oxygen inhibition layer. Source

The consequences of oxygen inhibition include:

- A tacky, sticky, or uncured surface layer on the printed object

- Incomplete polymerization, potentially affecting the object's mechanical properties

- Reduced biocompatibility due to the presence of uncured resin monomers

- Inconsistent surface finish, which can be particularly problematic for dental appliances

The thickness of the oxygen inhibition layer can vary depending on factors such as:

- The specific resin formulation

- The intensity and duration of UV exposure

- The ambient oxygen concentration

- The geometry of the printed object

For dental applications, where precision and biocompatibility are crucial, addressing the oxygen inhibition layer is particularly important. This is why various post-curing methods have been developed to mitigate its effects, including:

- Glycerin or water bath curing, which creates a physical barrier against oxygen

- Vacuum curing, which removes oxygen from the curing environment

- Nitrogen-based curing, which displaces oxygen with an inert gas

By understanding and addressing the oxygen inhibition layer, we, as dental professionals, can significantly improve the quality, consistency, and biocompatibility of our 3D-printed dental appliances.

The choice of post-curing method often depends on balancing the need to eliminate this layer with practical considerations such as equipment cost, ease of use, and compatibility with specific resin types.

Post-Curing Methods in Dental 3D Printing

While nitrogen-based post-curing is an emerging technology, it's essential to understand the landscape of established post-curing methods currently used in dental 3D printing.

The choice of post-curing method often depends on factors such as the specific resin being used, the type of dental appliance being produced, and the desired material properties.

As dental 3D printing continues to evolve, dental professionals should stay informed about these various methods and their applicability to different situations in the dental practice or lab.

UV Light Curing

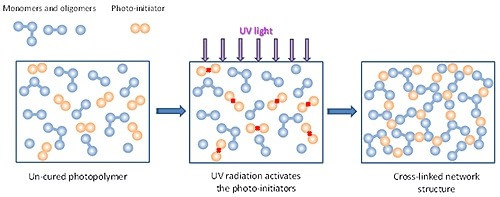

UV light curing, as mentioned, uses ultraviolet light to initiate and complete the resin's polymerization process. This method relies on the photochemical reaction triggered by UV light, which causes the liquid resin to solidify and harden.

Schematic of UV curing polymerization chain reaction. Source

During the UV curing, the printed object is exposed to UV light, typically in a light cure box or unit. The UV light activates photoinitiators in the resin, which then starts a polymerization chain reaction. This reaction causes the resin molecules to cross-link and form a solid structure.

This type of post-curing is by far the most common in dentistry.

Examples of UV light curing units include:

- Formlabs Form Cure

- Kulzer HiLite Power 3D Cure Box and cara Print LEDcure

- NextDent LC-3DPrint Box

- SHINING 3D Dental FabCure 2 Post-curing unit

- SprintRay ProCure 2

- Straumann P Cure light system

Glycerin Bath Curing

Glycerin bath curing addresses the oxygen inhibition issue by submerging the printed object in glycerin during the UV curing process. The principle is simple - create a barrier between the resin surface and atmospheric oxygen.

In this process, the printed object is placed in a container filled with glycerin and exposed to UV light. The glycerin, being more viscous than air and less permeable to oxygen, effectively prevents oxygen from reaching the resin surface during curing.

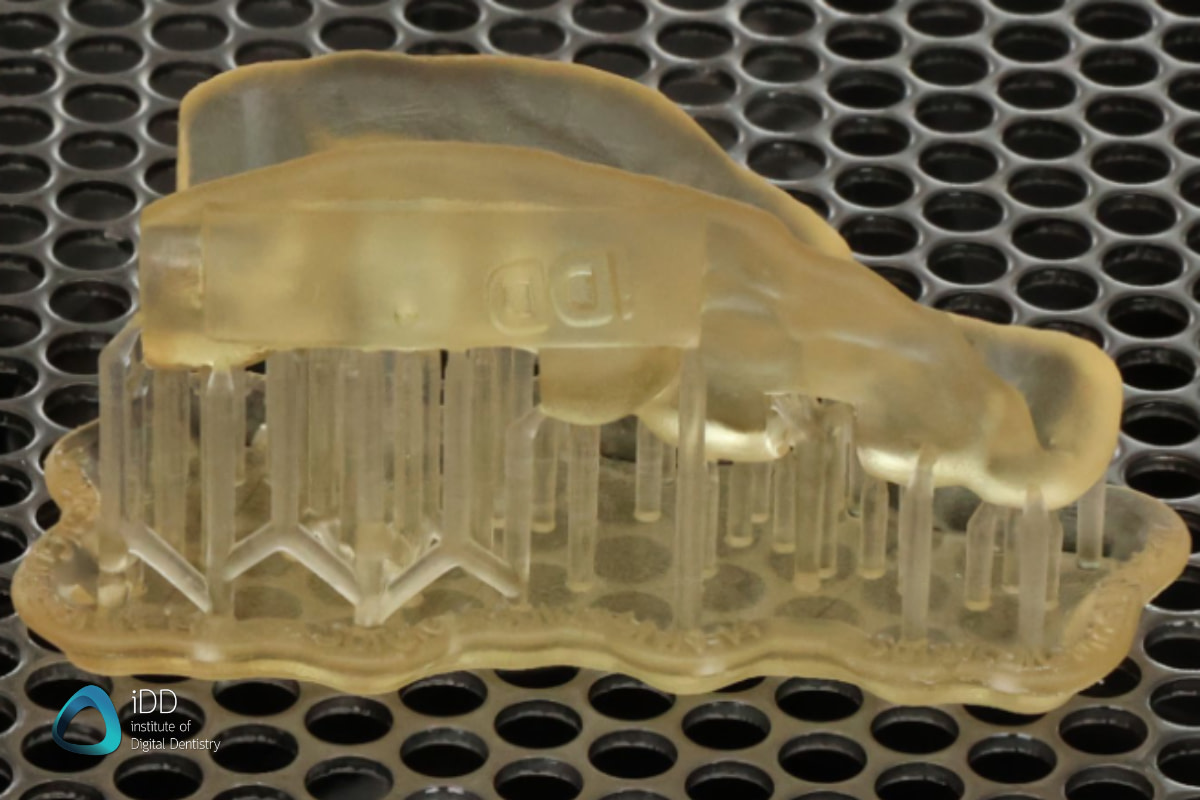

3D printed splint placed in glycerin to prevent an oxygen inhibition layer forming.

This method allows for more complete polymerization, especially at the print's surface. The result is often a smoother, less tacky surface finish than air curing. The glycerin environment also provides a more uniform curing condition, which can be particularly beneficial for objects with complex geometries or intricate details.

Most people use a simple plastic container with KY jelly in it. You may cure the print for a few seconds initially, then place it in the container with glycerin and then in your curing box for the final cure.

Water Bath Curing

Water bath curing works similarly to glycerin bath curing but uses water as the submersion medium. This method reduces oxygen inhibition during the curing process, albeit apparently less effectively than glycerin.

Water Bath from Whip Mix

In water bath curing, the printed object is submerged in water and then exposed to UV light. While water does provide some barrier against oxygen, it is not as effective as glycerin due to its lower viscosity and higher oxygen permeability.

The water bath can still offer improvements over air curing, particularly regarding surface finish and curing uniformity. However, it's important to note that water can interact with some resins, potentially affecting their properties or dimensional accuracy.

You can find examples of water baths as a post-curing unit here.

Vacuum Curing

Vacuum curing takes a different approach to addressing oxygen inhibition. Instead of using a liquid barrier, this method involves placing the printed object in a vacuum chamber during the curing process.

The principle behind vacuum curing is to remove air, and consequently oxygen, from the environment surrounding the printed object. By creating a near-vacuum state, the amount of oxygen available to interfere with the polymerization process is significantly reduced.

In practice, the printed object is placed in a specialized light curing unit with a vacuum chamber equipped with UV lights. The chamber is then evacuated of air before the UV curing process begins. This method can be particularly effective for reducing oxygen inhibition without liquid submersion, benefiting certain types of prints or materials.

Additionally, the vacuum environment may help remove volatile compounds from the resin during curing, potentially improving the overall quality and biocompatibility of the final product.

However, the effectiveness of vacuum curing (as a technique as a whole and non-exclusive to digital dentistry) can be limited for objects with complex geometries where air pockets might form and resist evacuation.

Examples of vacuum curing units include:

- Dentalfarm PHOTOPOL Vacuum & Gas Post-Curing Unit

- Atum3D Curing Station

Download the Full Comprehensive Guide PDF

Download the full PDF to get a full copy of this article to read later.

Get a high resolution printable copy of this review.

Nitrogen-Based Post-Curing

The last option is nitrogen-based post-curing, which involves generating a nitrogen-rich environment within the curing chamber by flooding the curing chamber with nitrogen, oxygen is displaced, theoretically allowing for more complete and uniform curing.

It's worth noting that nitrogen curing is widely accepted as the gold standard in the dental printing industry due to its effectiveness in optimizing the curing process.

Only a few dental curing units are nitrogen gas compatible. And how do you get the nitrogen anyway? Well, you must either order nitrogen tanks connected to your curing unit (which is annoying for a clinic) or generate nitrogen.

Ackuretta’s NFinity

On July 11, 2024, Ackuretta unveiled its latest innovation: the NFinity nitrogen generator. Ackuretta's NFinity unit can generate a 95% nitrogen-rich environment within the curing chamber of the CURIE Plus UV curing station.

The NFinity system generates nitrogen on-site, eliminating needing external nitrogen tanks or other cumbersome equipment. This is a huge advantage for clinics compared to having to order nitrogen tanks, and to be frank, it is quite a cool innovation.

It's important to note that while the theoretical benefits of nitrogen in post-curing are well documented in the scientific literature, the real-world performance of the NFinity system in diverse dental settings remains to be comprehensively evaluated.

Ackuretta NFinity Nitrogen Generator

As with any new technology, its efficacy and practicality will likely be scrutinized as it enters the market.

Dentsply Sirona’s Primeprint PPU

In 2022, Dentsply Sirona introduced its post-processing solution: the PrimePrint PPU (Post Processing Unit). Dentsply Sirona's PrimePrint PPU offers a comprehensive approach, integrating cleaning and curing processes to streamline the post-processing workflow for 3D-printed dental appliances.

PrimePrint PPU's functionality is a fully automated, two-step post-processing solution within a single unit. The system features separate chambers for cleaning and light curing. It is the only dental unit to automate the entire process.

Dentsply Sirona PrimePrint PPU

A key feature of the PrimePrint PPU is its use of nitrogen during the curing process, which is essential for its operation. The unit requires a nitrogen tank to be plugged into it. During curing, nitrogen gas is used to 'push out' all the oxygen in the chamber, helping preserve the material properties of the printed objects.

Graphy’s TERA HARZ Cure

Released in 2023, Graphy unveiled its latest advancement: the TERA HARZ Cure (THC) post-processing unit. Graphy's THC system introduced its third-generation nitrogen curing machine, leveraging both nitrogen and heat to potentially revolutionize the post-processing of 3D-printed dental appliances.

At the core of the THC 3rd generation's functionality is its ability to create a controlled, nitrogen-rich environment while simultaneously applying precise heat treatment. The system can maintain a high-purity nitrogen atmosphere (up to 99.9%) within its curing chamber. At the same time, it can reach temperatures up to 180°C (356°F), far exceeding the capabilities of traditional UV-based post-curing units.

The THC 3rd generation generates nitrogen on-site through an integrated nitrogen generator, eliminating the need for external nitrogen tanks or frequent gas refills.

Graphy TERA HARZ Cure

This nitrogen and heat-based approach addresses common challenges in 3D printing post-processing, such as incomplete curing, residual monomer content, and inconsistent mechanical properties.

It is interesting to note that this may be the next market trend for dental 3D printing - curing units that can generate nitrogen themselves.

NK-Optik Otoflash G171-6

Manufactured by NK-Optik GmbH, a German company specializing in light curing technology, the G171-6 was explicitly designed for the post-curing of 3D printed objects, particularly those used in dental and hearing aid applications.

The Otoflash G171-6 is known for achieving thorough curing, potentially improving the mechanical properties and biocompatibility of dental appliances. Thanks to its nitrogen purge capability, it is particularly suitable for applications requiring a high-quality surface finish and optimal material properties.

However, while the Otoflash is a popular and effective device, it represents just one approach to post-curing in the rapidly evolving field of dental 3D printing. Dental professionals should consider their specific needs, workflow, and the types of appliances they produce when evaluating post-curing solutions.

NK-Optik Otoflash G171-6

Dentalfarm PHOTOPOL Vacuum & Gas Post-Curing Unit

Notable for offering both vacuum and nitrogen gas post-curing options in a single unit. The system allows for post-curing in either a vacuum environment or under nitrogen gas, with the ability to switch between these methods depending on the application.

For nitrogen-based curing, the PHOTOPOL features a gas inlet that can be connected to a nitrogen source. When using the nitrogen function, the unit first creates a vacuum in the curing chamber to remove oxygen, then floods the chamber with nitrogen gas to create an inert environment for curing. This two-step process helps ensure more complete displacement of oxygen compared to simply flooding with nitrogen alone.

However, like the Dentsply Sirona PrimePrint PPU, the PHOTOPOL requires an external nitrogen source - it does not generate nitrogen internally like newer systems such as the Ackuretta NFinity or Graphy TERA HARZ Cure. This means dental practices need to maintain a supply of nitrogen gas cylinders when using the nitrogen curing feature.

Dentalfarm PHOTOPOL Vacuum & Gas Post-Curing Unit

Comparison Table of the Different Post-Curing Methods

Method | Principle | Pros | Cons | Best Suited |

|---|---|---|---|---|

UV Light | Uses UV light to initiate polymerization |

|

| Basic applications with less stringent requirements |

Glyercin Bath | Submerges print in glycerin during UV curing |

|

| Appliances requiring high surface quality |

Water Bath | Submerges print in water during UV curing |

|

| A budget-friendly option for improved surface finish |

Vacuum | Cures print in vacuum chamber |

|

| Prints sensitive to liquid submersion |

Nitrogen | Cures print in nitrogen-rich environment |

|

| High-precision appliances requiring optimal properties |

Download the Full Comprehensive Guide PDF

Download the full PDF to get a full copy of this article to read later.

Get a high resolution printable copy of this review.

Applications of Class II Biocompatible Resins in Dental 3D Printing and Recommended Post-Curing Methods

Now that we've explored the various post-curing methods and technologies available in dental 3D printing, it's important to understand how these techniques apply to specific dental applications.

Biocompatible resins are used in a wide range of dental devices, each with unique requirements for strength, flexibility, aesthetics, and patient comfort. Class II biocompatible resins are specifically designed for long-term use in the oral cavity, making them crucial for many dental applications.

In the following section, we'll go over some common applications of Class II biocompatible resins in dental 3D printing and recommend the most suitable post-curing methods for each.

Occlusal Splints and Night Guards

Occlusal splints and night guards are 3D printed using Class II resins for long-term treatment of teeth grinding and temporal mandibular jaw (TMJ) disorders. These appliances require high wear resistance and patient comfort. For post-processing, the recommended methods are glycerin bath or nitrogen-based curing. These methods ensure complete polymerization, reducing the risk of uncured resin irritating oral tissues and enhancing overall durability.

You can follow our step-by-step guide, “How to Candy Coat 3D Splints and Nightguards,” which covers glycerin bath curing.

Surgical Guides

Surgical guides can be 3D printed to aid in precise implant placement. These guides must be rigid, biocompatible, and able to withstand multiple sterilization cycles. The recommended post-curing methods are vacuum or nitrogen-based curing. These methods provide thorough curing without dimensional changes, crucial for maintaining accuracy over multiple uses.

Temporary Crowns and Bridges

Temporary crowns and bridges are 3D printed with Class II resins when extended provisional restorations are needed. These prosthetics must mimic natural teeth aesthetics and withstand chewing forces over prolonged periods. The recommended post-curing method is a glycerin bath followed by UV light curing. This combination ensures a smooth surface finish and complete curing for improved strength and aesthetics, crucial for long-term oral use.

Dentures (Full and Partial)

Full and partial dentures can be 3D printed using Class II resins to replace missing teeth for extended periods. These prosthetics demand high durability, aesthetics, and comfort for daily wear. For post-processing, nitrogen-based or vacuum curing is recommended. These methods ensure thorough curing of thick sections and help maintain color stability, essential for long-term use.

It's important to note that while these recommendations are based on general best practices, the optimal post-curing method may vary depending on the specific resin used and the manufacturer's guidelines.

Always consult the material’s guide sheet and follow the manufacturer's recommendations for the best results.

What are the Benefits from Proper Curing?

Besides eliminating the oxygen inhibition layer, what are the added benefits of proper curing?

Enhanced Mechanical Properties

Post-curing, regardless of the method, can improve the mechanical properties of printed dental appliances. Nitrogen-based and vacuum curing have shown up to 25% higher flexural strength in some studies.

This increase in strength is particularly beneficial for applications such as dental splints, temporary crowns, and bridges, where durability is crucial. Enhanced mechanical properties may result in longer-lasting appliances and potentially reduce the need for replacements or repairs.

Improved Surface Quality

Glycerin bath, water bath, vacuum, and nitrogen-based curing methods can yield higher-quality prints with fewer sticky areas and cracks than traditional UV curing in air.

This improvement in surface quality leads to smoother and more accurately fitting surfaces for dental appliances.

For patient-specific items like clear aligners or dentures, enhanced surface quality might translate to improved comfort and better aesthetic outcomes. Additionally, smoother surfaces may be less prone to bacterial adhesion, potentially contributing to better oral hygiene.

Better Aesthetics

Curing in oxygen-free or oxygen-reduced environments (such as in glycerin, water, vacuum, or nitrogen) has been found to enhance the aesthetics of transparent resins and avoid distorted appearances that can occur after post-curing in air.

This could be particularly important for clear resins such as those used in splints, but also consider the importance of color stability and translucency for printed veneers, etc.

Surgical guide before curing.

Surgical guide after curing.

Increased Biocompatibility

Post-curing methods that reduce oxygen exposure during the curing process have been associated with reduced residual monomers, potentially resulting in higher biocompatibility of dental appliances.

This is a critical factor for any dental product in prolonged contact with a patient's oral tissues. Higher biocompatibility could mean reduced risk of allergic reactions or irritations, contributing to better patient outcomes and potentially fewer complications.

More Consistent Results

Advanced post-curing methods have been reported to maximize the consistency of 3D-printed applications and ensure even curing. In a field where precision is paramount, consistency can significantly impact the quality of care.

More predictable outcomes could lead to fewer adjustments, remakes, or chair time, potentially improving both efficiency and patient experience.

Faster Curing Times

With the oxygen inhibition effect reduced or negated in methods like glycerin bath, vacuum, or nitrogen-based curing, some sources suggest that curing can happen faster and more evenly than traditional UV curing in air.

Reduced curing times could translate to increased productivity in dental labs and practices, potentially allowing for quicker turnaround times for patient appliances.

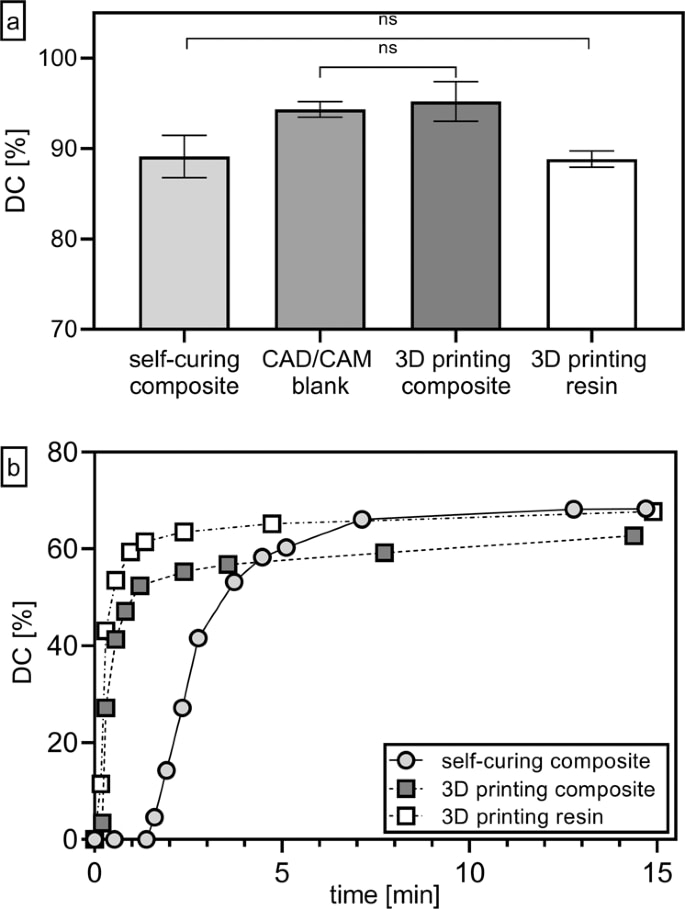

Higher Degree of Conversion

Some studies have shown that post-curing in oxygen-reduced environments improves the degree of double bond conversion in 3D-printed dental materials. A higher degree of conversion typically correlates with improved physical and mechanical properties of the final product, which could contribute to the overall quality and longevity of dental appliances.

It's worth noting that while these benefits are promising, the actual impact of different post-curing methods may vary depending on factors such as the specific resin used, the design of the printed object, and the particular requirements of each dental application.

As with any technology, dental professionals will need to evaluate how these potential benefits translate to their specific workflows and patient needs.

Moreover, adopting advanced post-curing systems may require initial investment and training. Each method has its own set of advantages and considerations, and the choice often depends on the specific needs of the dental practice or laboratory.

Degree of conversion (DC) [%] over time [min] during curing of the two 3D printing materials and the self-curing composite .Source

Industry Context

Nitrogen-based post-curing comes at a pivotal time in the dental industry's digital transformation. The global 3D printing medical devices market is experiencing significant growth, with dental applications being a major contributor.

In this rapidly evolving landscape, innovations in post-processing techniques could play a crucial role in shaping the future of digital dentistry. As adoption increases, the focus on improving every aspect of the production process to enhance quality, efficiency, and patient outcomes intensifies.

The dental 3D printing industry is addressing several key challenges:

- Biocompatibility

- Precision and Consistency

- Workflow Efficiency

- Material Properties

Nitrogen-based curing seems to attempt to address several of these challenges. However, they enter a competitive space where other companies are also innovating in post-processing techniques, including heat-based post-curing or combination UV-heat curing systems.

Looking Ahead

The continuous evolution of post-curing technologies in dental 3D printing points to an exciting future for digital dentistry. Several factors will likely influence the adoption and success of these various methods:

Clinical Validation

Right now, 3D printing is all over the place. There are so many different techniques, opinions, ideas, and workflows all over social media.

Comprehensive clinical studies will be crucial to validate the advantages of different post-curing methods in practical settings.

Dental professionals must look into peer-reviewed research and real-world case studies comparing the performance of appliances cured with various methods.

Long-term studies should address material longevity, patient comfort, and clinical outcomes across dental applications.

Regulatory Considerations

As 3D printing becomes more prevalent in dentistry, regulatory bodies may increase scrutiny on post-curing technologies.

Manufacturers must ensure their innovations meet evolving standards for safety and efficacy across different post-curing methods.

Given the global nature of the dental industry, this may involve obtaining new certifications or adapting to changes in regulatory frameworks.

Cost-Benefit Analysis

Dental practices and laboratories must carefully evaluate the costs of implementing different post-curing technologies against their potential benefits.

This includes initial investment in equipment, ongoing operational costs, maintenance, and potential energy consumption.

The analysis should also consider potential savings from improved efficiency, reduced material waste, and fewer remakes or adjustments for each method.

Integration with Existing Systems

The ease with which various post-curing technologies can be integrated into existing digital workflows will play a significant role in their adoption.

Solutions that offer seamless integration with popular 3D printers, design software, and other equipment may have an advantage.

The ability to retrofit existing post-curing units with new capabilities could also be a factor in adoption rates.

Material Compatibility

As post-curing technologies evolve, their compatibility with a wide range of dental resins will be crucial. Technologies that offer flexibility in this regard may be more appealing.

Collaboration between post-curing system manufacturers and resin producers could lead to optimized materials that take full advantage of various curing methods.

Training and Education

The dental industry's ability to provide adequate training and education on different post-curing technologies will be critical. This includes initial training and ongoing education to keep pace with technological advancements.

Dental schools may need to update their curricula, and continuing education programs, like iDD, will help keep dental professionals up-to-date on all available methods.

Patient Outcomes

The success of any post-curing technology will ultimately depend on its ability to improve patient outcomes. Long-term studies tracking the performance and longevity of dental appliances produced with different methods will be essential.

Factors such as patient comfort, aesthetic satisfaction, and functional performance will all play a role in determining the value of each post-curing technique.

Sustainability

As environmental concerns become more prominent, the sustainability of dental practices may come under increased scrutiny. Post-curing technologies that can demonstrate reduced waste or energy consumption may have an advantage. The environmental impact of different methods will need to be evaluated against their potential benefits.

Artificial Intelligence and Automation

The future may see increased integration of AI and automation in dental 3D printing workflows, including post-processing stages. AI could optimize curing parameters based on specific appliance designs or material properties across different post-curing methods.

Market Competition and Innovation

As the benefits of various post-curing methods become more widely recognized, competition in this space is likely to increase. This could drive further innovation, potentially leading to more efficient or cost-effective solutions across all methods.

Changing Dental Practice Models

The evolution of dental practice models, including the growth of dental service organizations (DSOs) and increased specialization, may influence the adoption of new post-curing technologies.

Larger organizations may be better positioned to invest in and implement advanced post-curing technologies, potentially driving wider adoption.

Conclusion

As dental 3D printing advances, researchers and manufacturers continue to innovate in post-curing technology. These developments are driven by the need for improved material properties, enhanced biocompatibility, and more efficient production processes.

Understanding the various post-curing methods available is crucial for dental professionals seeking to optimize their 3D printing workflows and produce the highest quality dental appliances.

If you are just printing models, sure, it may matter less to you, but with the rise of printing splints, surgical guides, and restorations, proper post-curing is now more important than ever.

While various post-curing methods show promise, their value will be determined through practical application and ongoing research in diverse clinical settings.

One thing is for sure - the oxygen inhibition layer must be controlled.

Leave your comments below; I would love to hear your thoughts.

Download the Full Comprehensive Guide PDF

Download the full PDF to get a full copy of this article to read later.

Get a high resolution printable copy of this review.

Great information presented.

Thanks for sharing

Thanks for reading!