The Form 3B+ is one of the most popular 3D dental printers around. In recent years, it has faced stiff competition as the printer market has completely blown up with many new products. Can Formlabs dental keep their once formidable lead?

The company attempts to make 3D printing as easy as possible, which may be attractive to the hundreds of thousands of dental professionals worldwide considering getting into 3D dental printing.

I’ve been 3D printing in my clinic for over six years, and in that time, I’ve been lucky enough to use over eight different printers from brands such as Asiga, SprintRay, the Primeprint, NextDent, UNIZ, and, of course, Formlabs.

While you might know iDD for our unbiased and objective intraoral scanner reviews, this year, I’m making it a goal of mine to review as many 3D printers as possible.

If you have any printers you’d like me to review, leave a comment and I’ll put them at the top of my list.

You can watch this review or read a more in-depth breakdown below.

Enjoy!

Background on Formlabs

Formlabs was established in 2011 by MIT alumni Max Lobovsky, Natan Linder, and David Cranor. Formlabs had an almost meteoric rise, as they managed to raise $3 million in a Kickstarter campaign that allowed them to launch the Form 1 in 2012. They launched the Form 1+ in 2014, the Form 2 in 2015, and a string of other printers, wash and cure units over the next decade.

Formlabs has always focussed on providing accessible, high-resolution printers. The Form 1 brought professional-grade stereolithography (SLA) technology to a broad audience at an affordable price point - which is why it was so popular - and they’ve continued to develop printers in line with their ethos of making 3D printing more accessible.

Over the years, Formlabs has established itself as a widely recognized name in the 3D printer industry and has since entered the dental market.

Our first ever printer in the clinic was actually the Form 2. And it continues to work to this day. So now, with the latest Form 3B+ the question is, is this a printer you should consider for your practice?

Get The Full Review Details

Access the Full Formlabs Form 3B+ Review as a PDF so you can read this when it suits you. You can download it too!

Formlabs 3B+ Print Speed

The Formlabs 3B+ is based on SLA technology, which is slower on average than its DLP or LCD counterparts. It is not the slowest printer on the market, but it is nowhere near being the fastest.

Standard models will take around 60-90 minutes to print with the Formlabs 3B+. Because of how SLA technology works, printing multiple models is not as fast as LCD or DLP either.

However, Formlabs does combat this with faster-to-print draft resins and larger layer thicknesses. Tinkering with all of this, you can get model printing in around 30-45 minutes. But this is only for models.

When it comes to crowns and other indications, it is also not the fastest. A single crown takes about 50-60 minutes to print, for example.

Once again, the main reason that the 3B+ isn’t the fastest printer is because all Formlabs printers are SLA printers - which use a laser to cure each point in each layer during the printing process. SLA just cannot compete with LCD or DLP, which print layer by layer. So, although SLA printers are known for their surface finish, speed is not the strongest suit of the printer.

For example, it will print a splint or surgical guide in around one and a half hours to two hours, a model in around two hours, and a single crown restoration in about an hour.

To help address the speed compromise, Formlabs has just recently added a Fast Arch Printing mode, which can print one model in under 10 minutes and four arches in under 20 minutes using Draft Resin at 200 microns.

This is an impressive speed for an SLA printer, but it is restricted to their draft resin, and for a dental setting, that means only printing models. All other dental indications tend to be slower than LCD or DLP printers.

Formlabs 3B+ Ease of Use

Once you’ve set the Formlabs 3B+ up, the company’s slogan of ‘dentistry made easier’ really shines through. Everything is incredibly user-friendly when it comes to the software. It’s really easy to delegate printing to staff, and the overall process is a breeze and can be done by anyone on the team.

The software and menus are clear, intuitive, and easy to understand. The printer warns you if you have done anything wrong, such as adding the wrong resin for the job or inserting the wrong resin tank. It is generally an extremely user-friendly system. For example, the printer's screen tells you when you have inserted a build platform, resin tank, and resin cartridge. The printer won’t let you start printing if any of these elements are missing. If any issues are identified, it will clearly advise you to rectify them.

The resin tray system has a wiper to always keep the resin mixed, and auto-filling resin cartridges make it one of the easiest printers to operate. The software is also great; more on that below.

Reliability of Formlabs 3B+

The Formlabs 3B+ just works. It’s a super-reliable printer.

It might not be the fastest, but failed prints are rare using this printer. The printer software works well, and support is generated intelligently by the AI where required. The printer is very easy to use.

We have been using Formlabs for years, and overall, I find the entire system very dependable. If everything is maintained, it’s very unlikely that you’ll run into problems.

The Form 2 Printer had an issue with the resin tank chip (used to read when a tray is inserted) wearing out and breaking down, but with the Form 3B+ this has been improved.

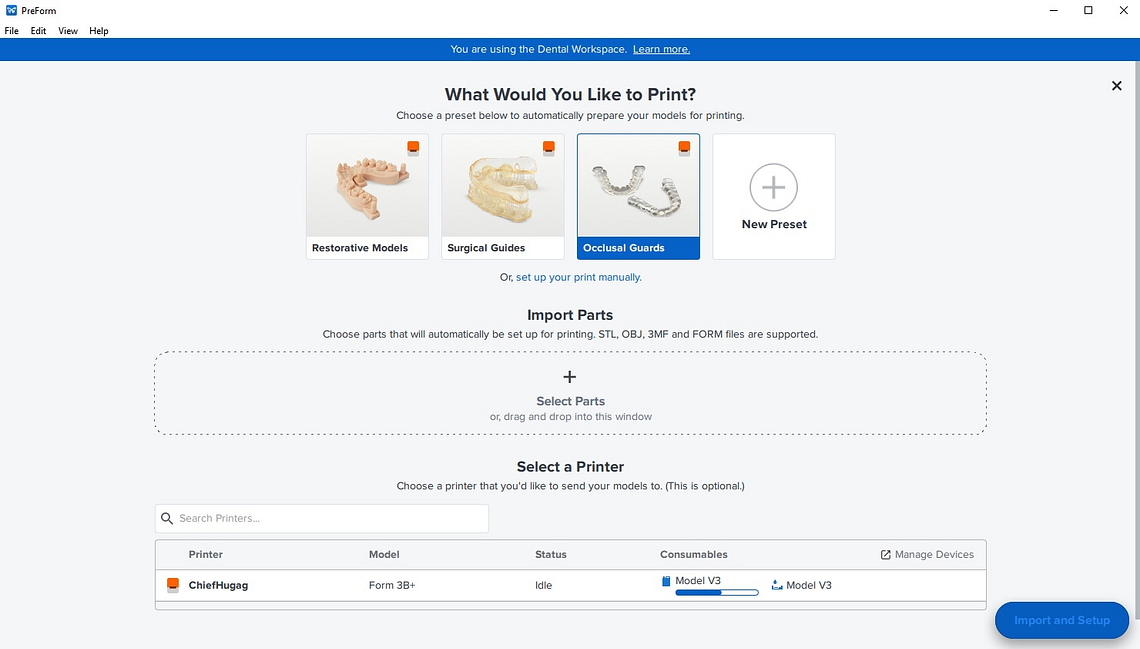

Formlabs 3B+ 3D Printer Software - PreForm

PreForm by Formlabs is one of the best printer software on the market for ease of use.

It’s modern looking, easy to use, intuitive, and makes printing a breeze. This is thanks to the software, which simplifies everything. You just drag STLs into the software, and then within 1-2 clicks, you have supports in place and can start printing. There are no buttons on the screen that aren’t used, etc.

The company has also taken the dental market seriously and released a dental version of the software called PreForm Dental, making the entire workflow even better.

If you don't know already, most 3D printer companies sell their printers to various industries, like jewelry. Some software looks like engineering software and is quite complicated. With PreForm Dental, the company has just focussed on what is essential for dentists.

Rather than insert the files and have to arrange them manually, the company has rethought the workflow. Before importing files, you simply choose your indication of choice and then upload the STL. The software will do everything else for you automatically, ready to be sent to the printer.

It has been programmed to know what the required nesting parameters are for a splint vs. a surgical guide vs. a model, for example. The software also allows you to create your own custom presets and save them so you can automate this step as much as possible.

The only thing that needs to be added is an AI or CAD design feature, which I would love to see in the future.

Formlabs do have several validated CAD integrations, such as with Medit Link, 3Shape, and exocad, and partners with design services to cover this gap.

Overall, we hardly ever had any issues with printing, and that’s thanks to the software. It even has a one-click print function in which any design will be orientated, placed on supports, and ready to print in a single click. Furthermore, the software has a great online cloud system and printer management interface.

Formlabs 3B+ Material Options and Availability

Unfortunately, this is the Achilles' Heel of Formlabs printers.

Formlabs is a closed system (but there are whispers of this possibly changing). This means there are a limited number of resins available for you to use. Most notably, you can’t use KeySplint Soft or many other popular third-party resins.

In saying that, the company does offer resins for every single indication. So it is not like you cannot print something. The issue is that Formlabs-approved resins are not market disrupters or best in class. For example their crown resin is average and is made by BEGO. It says permanent crown resin, but I would just treat it as a temporary material.

The company is clearly aware of this gap in its portfolio and has been busy releasing new resins such as a new soft splint material, so it is clear they are trying to stay competitive it seems. They launched a new "Premium Tooth Resin" just last month at CES 2024.

Overall, thinking of their entire resin line-up - the model resin works well but looks a bit off with higher than usual translucency for a model resin. The draft resin is excellent and fast but grey. The crown resins are pretty dated and don’t look the best. The surgical guide resin works well, yet some users don't like the yellow/orange hue compared to transparent resins, etc.

To be honest, the only essential resins to consider is restorative resins and splints. Surgical guides and model resins all work across the entire board. It is the prosthetics we want to deliver in the mouth that vary a lot between different resins.

Formlabs also uses a cartridge-based system, so you do not have to manually pour any resin into the trays or worry about it staying topped up. If there is resin in the cartridge, the printer will keep the tray full. There are a lot of opinions on cartridge-based systems vs bottle resin systems.

Some people love cartridges for their simplicity, and others prefer pouring resins via bottles as these resins tend to be a bit cheaper on average. Personally, cartridges do help minimize spills and provide a clear workflow.

Formlabs 3B+ 3D Printer Price

This is one of the strongest aspects of the Formlabs 3B+ system. The cost is competitive.

At around $10k USD you can buy an entire Formlabs 3B+ system, which is an excellent entry point for those looking at printing.

Prices vary depending on your region, so check in with your distributor for up-to-date pricing.

Formlabs 3B+ Printer Technology

Low Force Stereolithography.

The printer uses an optics engine, one Light Processing Unit utilizing 250 mW laser power, and a 25-micron XY resolution.

Slow but nice finishes.

Formlabs 3B+ Build Platform Size

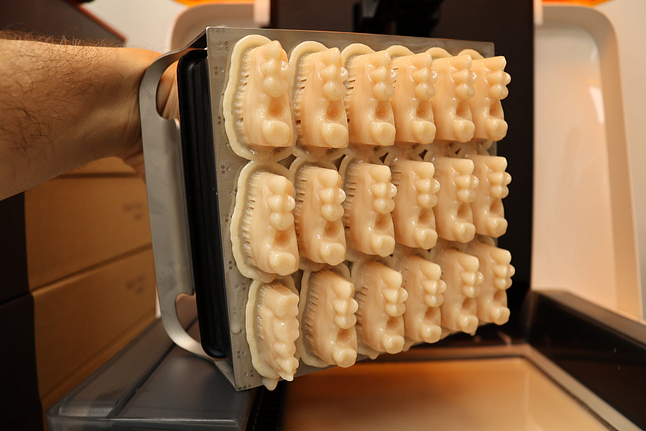

The build platform is large. Great for printing multiple models. You can easily fit around eight models on this platform, laid flat.

When printing dental prosthetics such as splints, guides, and restorations on Form 3B+, you are spoiled for space. Perfect for a lab that is printing a lot, but maybe a bit overkill for a clinic that may print a couple of items per week.

Unfortunately, no smaller build platform options are available for Formlabs 3B+ like how SprintRay and Ackuretta offer for things like crowns, for example. You can still print crowns on a build platform with no problem, but it is a bit overkill, and smaller build platforms are faster.

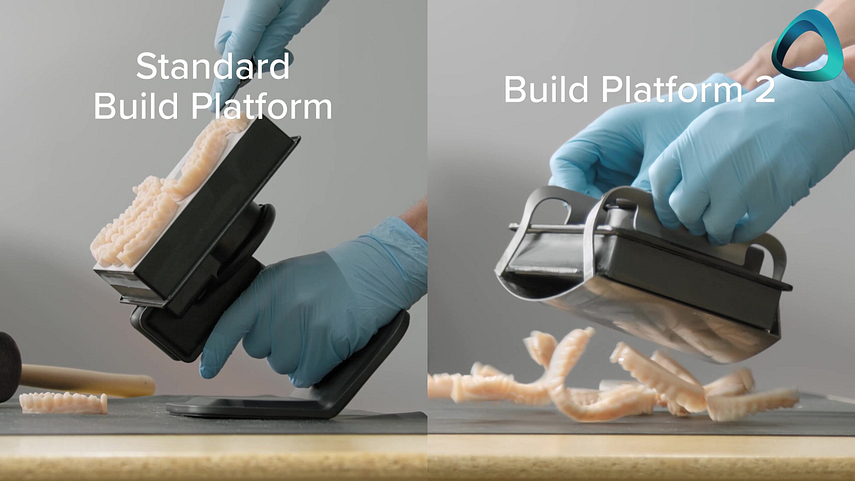

The company has, however, innovated in the build platform space in a different way rather than just offering different sizes - the new Build Platform 2 enables easy removal of all printed products by using a propriety flexing build platform. This makes printing and removing multiple models a breeze.

Basically the Build Platform 2 makes it simple to remove prints from the platform without having to essentially chisel them off with a spatula. One thing to note is that if you are using multiple different resins, it is a lot easier to keep one platform for each resin, otherwise you have to undo the entire platform and clean it thoroughly to prevent mixing up resins. I would say if you only want to buy one Build Platform 2 - keep it for your model resin.

Build Platform Specifications:

Total volume: 145 × 145 × 185 mm

Build plate area: 21,025 mm2Formlabs 3B+ Set-Up Difficulty

Overall, the entire set-up is super easy and can be done in 10-20 minutes with no service tech required.

Formlabs shines in ease of use. The entire unboxing process is easy to do for anyone.

Turn the printer on and follow the on-screen prompts. Leveling the print bed itself is also simple, with smart and intuitive on-screen instructions and included tools.

There are also various tutorials and help online if you need it. Furthermore, here at iDD, we offer a 3D printing bundle that takes you through all the important concepts when it comes to 3D dental printing and getting successful prints. Check it out below.

Need 3D Printing Training?

Get comprehensive dental printing training with our 3D Printing and Design course bundle. The perfect course to get started.

Formlabs 3B+ Connectivity

The printer can be connected to your CAD station via ethernet to a network, direct connection, or WIFI. The printer allows you to connect it to the computer in many ways. It is super handy to fit any clinic or lab.

The WIFI is easy to set up and enables you to connect the printer to any computer in your practice and to the cloud, called the Formlabs Dashboard. This printer can also be controlled via Formlabs’ Dashboard and you can check on various printing metrics and statistics.

With a WIFI connection, you can send your print jobs remotely to your printer from anywhere you are. Of course, for a fully automated solution, you will need to remove any prints from the build plate - and that is where the Formlabs Automation Ecosystem fits in. Again, it is super handy for labs but less likely to be useful for clinics with lower-volume printing.Cloud

The Formlabs Cloud service works very well.

As mentioned, you can start prints entirely remotely. The interface is excellent, and printer statistics are a nice addition. With the new Form Auto feature, you can set up an entire automated production facility with the new Form Auto feature.

There's nothing much else to say except that it has a nice UI. The only thing missing is AI CAD designs or remote design service to be run by Formlabs like SprintRay does.

Formlabs 3B+ Heater

The Formlabs 3B+ has an internal heater. The heater makes sure the resin is heated to the right temperature before printing. It is actually critical in the entire process so those printers without heaters can be annoying to use.

The internal heater present in the printer works well. All resins are automatically heated to optimal temperature based on the resin chosen before starting the print job. You can also clearly see the current temperature on the printer LCD screen as it heats up.

The printer can also be ‘primed’ before a print job is sent, which heats the resin and prepares everything for immediate printing. A nice feature.

Formlabs Washing / Curing Machines

The Formlabs 3B+ comes with a complete system.

Formlabs sells two types of wash units: one manual and one automatic.

The ‘Finish Kit’ which is essentially two plastic boxes for holding IPA alcohol (and is generally helpful for any printer you may have), or the Form Wash, which is an automatic washing unit that works quite well and is automatic in the sense that it goes down with your printables when started and then rises automatically once the wash time is complete.

This is to ensure any prints are not left in IPA, which is a big mistake in 3D printing. Also, it means you can set the wash to start and leave the clinic/lab knowing well that the prints will be removed from IPA and dry.

Formlabs Finish Kit unboxing.

Putting a surgical guide in the Form Wash.

Then, there are the curing units. Form Cure was the first unit and left a lot to be desired in terms of speed. In fact it was very slow.

Then the Fast Cure was released, which is their newest product and is blazingly fast, allowing you to cure all dental applications from 1 to 6 minutes. This unit does not require preheating thanks to its 56 powerful LEDs in the box, which differentiates it from the Form Cure. It is an OEM product of Graphy.

Presets are already loaded on the screen per the material, but you can also create your custom profile to cure other materials.

After curing, you then carry out standard post-processing. Remove the support structures, etc. The company provides it all for you in the box.

This is a complete setup with validated resins. With the company's newly released Form Auto and Fleet Control, you can scale your printing significantly with automated part removal from the Build Platform 2.

Pros of the Formlabs 3B+ 3D Printer

Easy to use

I can literally train my DA in about 20 minutes how to take STLs, nest them to print, and post process. For things like ortho models, etc, this has saved me so much time, and in general, this printer is excellent for delegating to the team thanks to its user-friendliness. We use it frequently in our practice for models and surgical guides.

Reliable

The entire process just works, the printer is reliable. I seldom have to worry about having any issues with it. Failed prints are rare and the company made big improvements with their new Low Force SLA Technology and PreForm Dental software.

Good sized build platform for dental applications

The printer has a pretty small footprint overall and a decently sized build platform for a range of applications. Many LCD and DLP printers these days can fit two or three models and a splint or two. Great for a clinic setup, but for any higher volume printing, you probably want a bigger platform. With the Formlabs 3B+ you can fit easily 4,5,6 models flat down and thus have them all going in one print.

Training models printed for iDD live courses.

Well-priced

The Formlabs 3B+ is competitively priced. Here in New Zealand, you can get the printer for around $12,000, which is around $7,000 USD. With the wash and cure and everything, you can expect to spend around 9000 USD for the entire package.

Cons of the Formlabs 3B+ 3D Printer

Speed

We already talked about speed. It is not the fastest on the market and can't compete with LCD or DLP printers in speed.

Lack of resins and materials

The main downside I see, and I hope the company addresses in the future, is the resins.

Dental printing is a resin game. I cannot stress that enough. It doesn’t significantly impact how fast the printer is unless you focus on same-day dentistry, such as single-visit crowns or splints.

For most other indications, such as a surgical guide or model, whether a printer does it in 45 minutes or 2 hours, in reality, it does not have a huge impact on the workflow unless, again, you need it on the day.

The key for any person thinking about 3D printing is which resins I can print.

Although Formlabs Dental has more than 15 resins in its portfolio, including models, surgical guides, temps, etc., these all work fine. They print well and are geometrically accurate.

The issue is they often are not the best on the market. The company needs to focus big time on dental resins to be competitive. Especially with the likes of SprintRay, Dentsply Sirona etc really pushing the dental market.

Get The Full Review Details

Access the Full Formlabs Form 3B+ Review as a PDF so you can read this when it suits you. You can download it too!

Conclusion

FORMLABS 3B+ RATINGS

Print Speed

Reliability

Ease of Use

Software

Material Options

Investment Cost

Wash

complete system

Cure

complete system

FORMLABS 3B+ FEATURES

Printer Type

SLA 250 mW laser power 25 micron

Build Platform Size

Medium 145 × 145 mm

Set Up Difficulty

Easy

Cloud Software

Yes

Open System

Closed

Built-in Heater

Connectivity

USB, WiFi and Ethernet

The Formlabs 3B+ is not the fastest printer on the market, and in fact its use for same-day dentistry is tricky to argue. It is, however, one of the most reliable and easy-to-use printers available.

Where this printer excels is its decent economic value and easy delegation. Formlabs printers were widely popular because of this and were adopted quite a lot early in dental printing.

Given the resin limitations, it is usually best for clinics/labs who want an easy-to-use and delegate printer for things like models and surgical guides. It is a great printer for novices, and the company is working hard to release new validated resins.

Overall, the printer technology works well; it does the job. The company has good hardware and a proven workflow. It is now up to the market to decide if SLA printers can compete with the large influx of LCD and DLP printers that are being released on the market.

That is everything for this review of the Formlabs 3B plus 3D printer. Let me know your thoughts, and leave your comments below.