Let's talk about Filament Printers for a second...

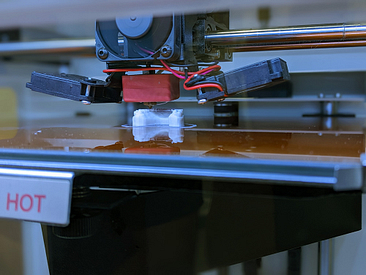

Fused deposition modeling (FDM) is what most people think of when they hear 'printing'.

Rather than a vat of resin, the printer works by extruding thermoplastic filaments into the desired 3D shape.

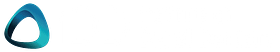

Model printed out of bright red Z-PLA Pro on the Zortrax Inventure

Up until recently, FDM printing has been arguably more accessible and available to the public consumer compared to traditional resin printing.

This is because it is:

- Cheap - FDM resins are typically much cheaper than SLA resins. E.g. 1 kg of polylactic acid (PLA) can vary from $39-70 AUD. 1 kg of model resin can start from double that price. PLA is a type of plastic commonly used in FDM printing.

- Easy to maintain - Nozzles and internal parts are easier to replace in FDM printers compared to LCD screens or FEP in SLA printers. FEP or fluorinated ethylene propylene, is a the thin film at the base of your resin vat to prevent prints sticking to it.

- Safer to handle overall - no cleaning agents and curing required. Some filaments such as PLA are compostable.

- Smaller footprint - no wash or cure units.

Overall, with the exception of ceramic and metal printing, they are also stronger with specific filaments engineered to be used as working mechanical parts e.g. may contain carbon fiber components etc.

So why hasn't FDM taken off in the dental setting? It's arguably safer, cheaper, better for the environment, and has a smaller footprint and simpler workflow.

In my opinion there are several reasons for this:

- FDM is slow - a typical dental model can be fully processed in a SLA printer in less than 45 minutes. The same model would take more than an hour in a Zortrax Inventure FDM printer.

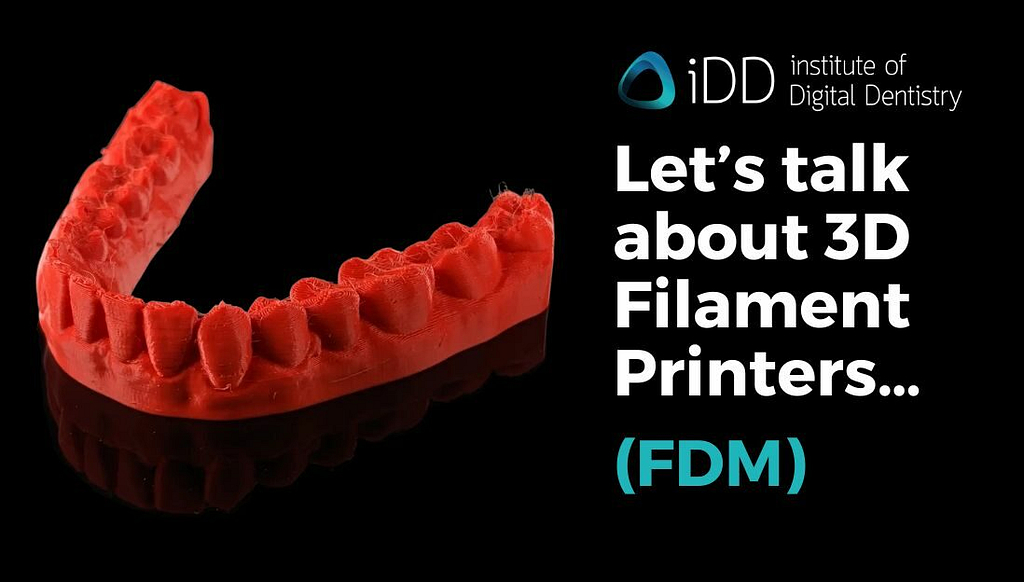

This is exponentially worse when printing multiple objects. The duration of a print in resin printers is determined by the vertical (Z-axis) height, irrespective of number of objects, whereas in FDM printers, duration is determined by how fast molten plastic spaghetti can be squeezed out of each nozzle. - Poor detailing - while the details achieved in an FDM printer are decent enough for aligners, retainers and mouth guards, they definitely cannot compete with resin printing. You certainly won't be seeing intricate molar anatomy with FDM printers. However, note: cross-arch accuracy is great on FDM printers as there is no shrinkage during a cure phase.

- Poor marketing? - resin printers won the cool factor race hands down. Search resin printer on Google Images and you can see the awesome stuff you can achieve. Now do the same for FDM printer. To make things worse, FDM printers just look plain ugly and many look like carbon copies of each other.

- Lack of material development specific to the dental field - while the dental 3D printing industry started off with dental model resin, it has branched off to a whole universe of dental-specific resins such as those for splints, surgical guides, etc. Due to poor uptake, FDM hasn't really moved anywhere specifically in the dental industry.

It is a bit of a shame as there is nice potential for FDM to be involved in the dental industry in a greater form.

Check out these models printed on the Simplex, a dental-specific FDM printer manufactured by Renfert Dental:

Models printed using Simplex by Reinfert.

Although not the most detailed printed models out there, these are totally usable for mouth guards, retainers, aligners and study models. Remember with FDM there is no need for IPA, washing, or curing units.

Admittedly, not everyone's cup of tea, but an easy set up which will cater for a niche portion of the dental market.

What are your thoughts about FDM? Leave your comments below!