Formlabs has just announced the release of their latest 3D printer - the Form 4BL. The new releases just keep coming this year.

This new large-format printer seems to be focused on high-volume dental production for medium to large dental labs and aligner manufacturers, rather than dental clinics.

Built on the Form 4B printer technology - but larger, the Form 4BL seems to offer the same high speed as the 4B but now with an even bigger build platform, a resin pumping system, and a bunch of new updates to PreForm (the software).

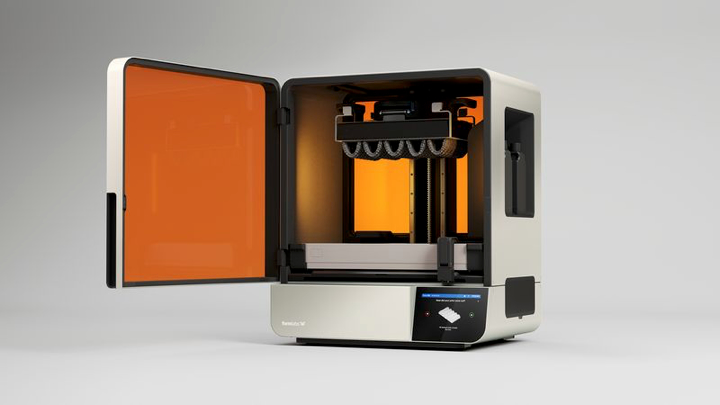

Form 4BL

Before we explore Form 4BL's features, here is some background about Formlabs' position in the 3D printing industry.

About Formlabs

Founded in 2011, Formlabs is a large player in professional-grade 3D printing technology in many industries. They work with the likes of Tesla, Hasbro, NASA, Google etc. Their Form series of printers are the ones typically used in dentistry.

Many years go, the Form2 printer was the leading printer in the dental market. It was the printer everyone seemed to have. It was our first 3D printer too. Since then, they have faced stiff competition with a rise of many other printers offering open systems and focussing on dental materials.

Recently the company released their latest printer the Form 4B, to try reclaim some of that early success, which is a much faster printer than the Form 2 and 3B, and now we have the release of the Form 4BL - which is a large format Form 4B.

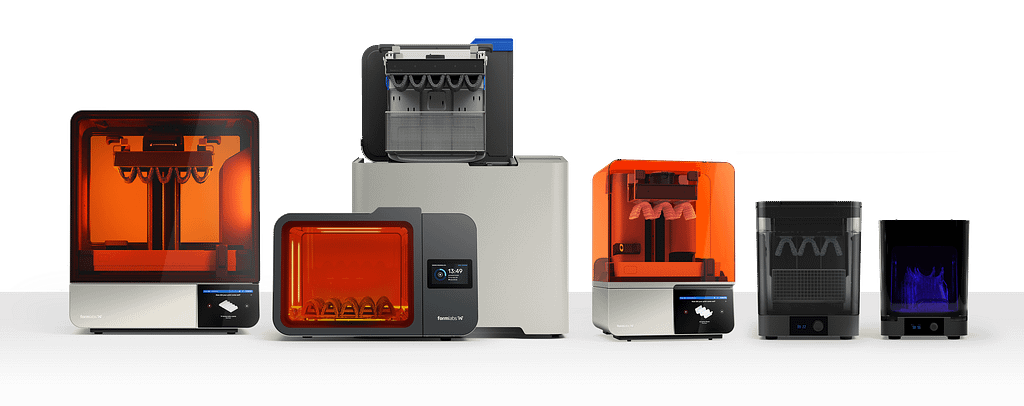

Formlabs product range

The Form 4B offers possibly better quality prints with a 50-micron pixel size and a build volume suitable for most dental applications. You can also print 25 micron layers on the Form 4B - you can read more about that printer here. Form 4B's success set the stage for Formlabs to develop a solution for even higher-volume production.

Now, let's dive into the specific features of the new Form 4BL.

Announced Key Features of the Form 4BL

Expanded Build Volume for High-Throughput Printing

The Form 4BL boasts a build platform surface that's 2.7 times larger than its predecessor, the Form 4B.

The size of the new build platform is 353 x 196 x 355 mm (13.9 x 7.7 x 14.0 in). This allows for printing up to 32 flat or 75 vertical dental models in a single print job.

This is frankly a huge build platform. Here are some other printer comparisons for reference:

- Asiga Ultra 50 = 192 x 108 x 147mm

- Shining 3D Accufab CEL = 192 × 120 × 180 mm

- Ackuretta SOL plus = 127mm x 218mm x 120mm

Image above is from the company.

This significant increase in throughput could drastically change workflows for high-volume labs. It means you may run a huge print job once rather than multiple jobs per day.

Rapid Printing Speed for Efficient Production

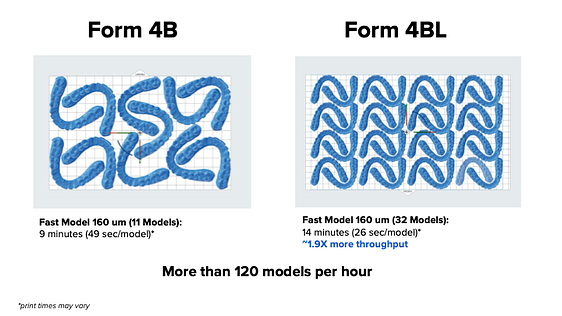

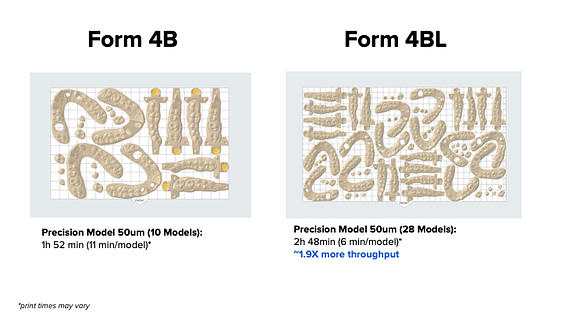

The company says the Form 4BL can print 32 models in just 14 minutes using Fast Model Resin at 160 μm layer thickness.

It prints 2.5-4x faster than the Form 3BL, depending on the material.

Print times are similar whether you’re printing one part or a full build of many parts, thanks to LCD technology.

Advanced Reliability Features for Maximum Uptime

The Form 4BL is designed for dependable large-format 3D printing.

The company laid out its feature set, including:

- Validated Print Settings

- Intelligent Control Systems

- Long-Lasting Consumables (Resin Tank rated for >75,000 layers, Light Processing Unit rated for 600k - 1.9M layers)

- Factory Calibration

- Remote Monitoring capabilities

Precision and Accuracy in Dental Model Production

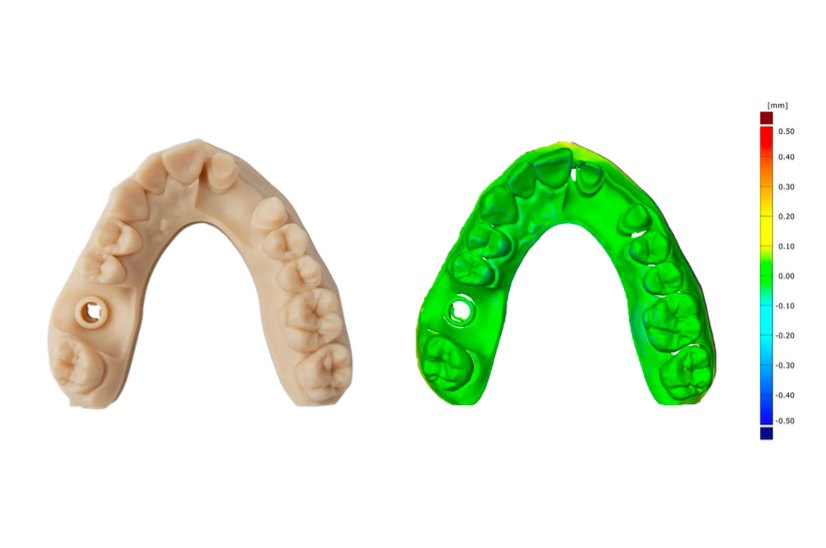

Formlabs reports that +95% of the print surface is within 50 μm of the CAD model for restorative models. The printer maintains repeatable accuracy across prints on a single printer and across printers.

Material Options for Diverse Dental Applications

The company announced this, which is interesting - the Form 4BL is compatible with over 10 dental-specific resins, including biocompatible options. Okay, that is not that interesting.

Then they said - it also supports Open Material Mode, allowing users to print with third-party resins. This is a sign of the times. Formlabs is opening up their printers.

The inclusion of Open Material Mode opens up interesting possibilities. We're keen to hear if this feature is important for your lab. Are you likely to experiment with third-party resins, or do you prefer to stick with Formlabs' validated materials?

I mean for models, any resin will work, right? Most people want open systems to access class II resins (restorative materials etc). Not really for models which this printer seems to be designed for. That said Formlabs’ Open Material Mode is also available on the Form 4B at a cost of 2499$. Formlabs printers are officially opening up!

Anyway, at launch the Form 4BL will support the following dental resin materials:

- Fast Model Resin

- Precision Model Resin

- Grey V5 Resin

- Dental LT Clear V2

- Dental LT Comfort V1.1

- Surgical Guide Resin

- Custom Tray Resin

Support for IBT Flex Resin, Premium Teeth Resin, and Castable Wax Resin will be added after launch.

Denture Teeth and Denture Base resins are not currently planned for the Form 4BL.

Integrated Workflow for Seamless Dental Production

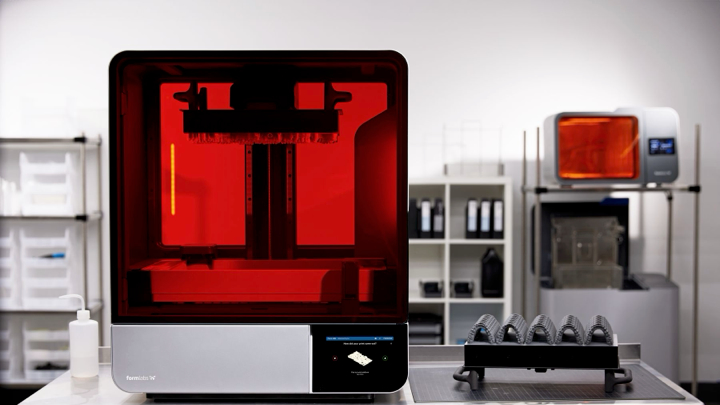

The printer integrates with Formlabs' ecosystem, including PreForm software, Form Wash L, and Form Cure L. It's compatible with the Resin Pumping System for 5L containers, reducing resin changes by up to 5x.

Cost-Effective Solution for High-Volume Dental Labs

Priced at $13,999, the Form 4BL aims to provide greater value at a lower cost compared to competing large-format printers. One comes in mind - HeyGears.

Formlabs claims the total cost of ownership for high-volume production (over 1 million aligners per year) is approximately 30% lower than using Form 4B machines which is mainly driven by increased efficiency and the fewer labor interaction needs to manage the fleet.

Enhanced Features for Optimized Dental Workflows

PreForm 3.41.0: Improved Software Capabilities

The new PreForm version includes some automatic AI and long requested features:

- Scan to Model & Hollowing: within the software itself you can convert intraoral scans to printable models with automatic drain hole creation for hollow models.

- Drain Holes: Add drain holes to existing hollow models within PreForm.

- Labels: Add customizable labels directly to models for improved part identification.

Seamless Integration with Dental CAD Software

Formlabs has introduced a new API that allows for deeper integrations with other software platforms.

This enables custom workflow automation and seamless integration with existing dental CAD software. But most interestingly the capability to automate batch production for labs printing hundreds of models per day with manual setup.

Let's see where that goes in the future... like Tesla's recent announcement, it seems to be all about automation these days.

Comprehensive Support for Dental Professionals

Formlabs offers a Dental Service Plan with personalized Q&A sessionsonboarding, proactive check-ins, and industry-leading support.

The company says before shipping, each Form 4BL undergoes a 60-point calibration and quality control inspection.

Form 4BL vs. Form 4B - What’s the Difference?

The Form 4BL represents where the company is focussing compared to its predecessor.

While it uses the same core technology as Form 4B, it's designed specifically for high-volume production environments - labs, basically, but some clinics, too.

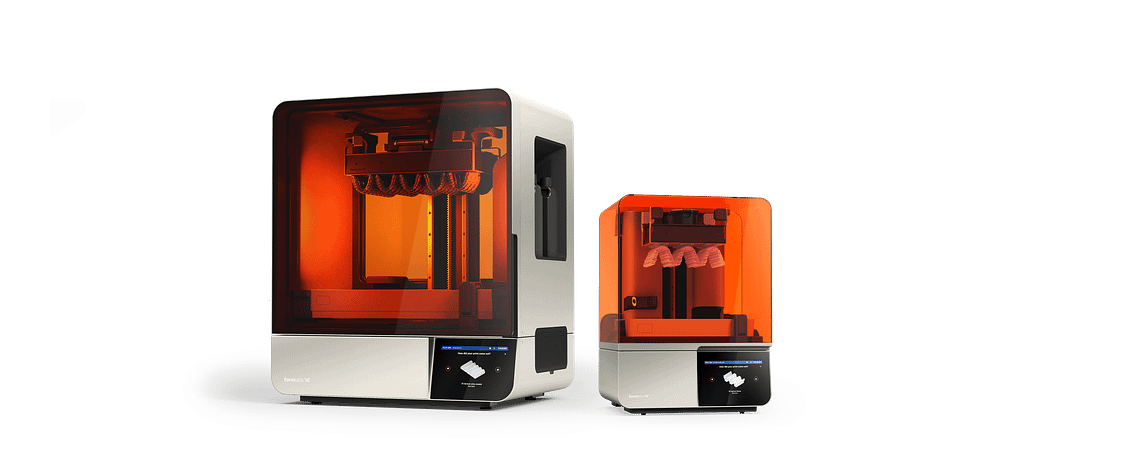

Form 4BL (left) and Form 4B (right).

Here are the key differences:

- Larger Build Volume: The Form 4BL offers a build platform that's 2.7 times larger than the Form 4B.

- Production Focus: While Form 4B is a general printer for a wide range of dental practices, Form 4BL is specifically focussed on medium to large dental labs and aligner manufacturers.

- Enhanced Workflow Integration: The Form 4BL is designed to integrate seamlessly with high-volume production workflows, including compatibility with 5L resin containers through the Resin Pumping System.

Note - The Resin Pumping System is also compatible with the Form 4B but adds a higher value to the workflow when used with the resin thirsty Form 4BL.

These differences position the Form 4BL as a complementary offering to the Form 4B, rather than a replacement.

Formlabs also has redesigned its resin cartridges and tanks, claiming to minimize plastic waste by 63%.

Ultimately, the Form 4BL is ideal for aligner manufacturers and labs.

Summary

The Form 4BL represents an interesting advancement in Formlabs' dental 3D printing offerings.

Its large build volume and integration with Formlabs' ecosystem could make it a powerful tool for labs looking to scale up their digital production. It basically replaces the Formb 3BL which had its limitation due to slow print speeds.

However, it's important to note that this printer isn't for everyone.

It's clearly positioned for medium to large dental labs and high-volume producers.

The Form 4B remains a better option for smaller practices or labs just getting started with 3D printing and looking into the Formlabs portfolio.

Finally, it's important to recognize that with the speed and accuracy of the Form 4BL and Form 4B, combined with the seamless integration of the Form Wash/L and Form Cure/L systems, Formlabs is putting in a lot of effort to provide a comprehensive and user-friendly solution for all dental 3D printing needs.

Now with the new Open Material Mode (opening up Formlabs printers to 3rd party resins), Formlabs is working really hard to be back in the game and to become the preferred choice for both dental practices and labs of any size.

Interesting times ahead and the 3D printing space is as competitive as ever.

Stay tuned for more updates, and let us know your thoughts in the comments below! Your experiences and insights are invaluable as we all navigate the rapidly evolving landscape of digital dentistry.

We'd love to hear how it compares to other solutions you've considered. What factors are most important in your decision-making process when it comes to investing in new production equipment?