If you want to see the future of digital dentistry, don't necessarily look in dental practices - look in dental laboratories.

This was crystal clear at LMT Lab Day 2025, where the sheer concentration of cutting-edge technology, digital dentistry solutions, AI and 3D printing made the concurrent Chicago Midwinter Meeting look almost conservative by comparison. If you are interested I did a full recap of that show too - read it here.

While both shows shared the same dates, Lab Day painted a strikingly different picture of the dental industry. The laboratory show wasn't just busy - it was packed. The crowds were noticeably denser, the conversations more technical, and the technology on display more advanced. This isn't just about different audiences; it's about different priorities and different stages of digital adoption.

What truly set Lab Day apart was its nearly complete embrace of digital workflows. Unlike the clinical-focussed Chicago Midwinter where traditional techniques (like physical impressions) still were present at the show, finding a booth focused on conventional laboratory processes at LMT Lab Day was like spotting a film camera at a smartphone convention. Every corner of the exhibition floor showcased some form of digital innovation - from AI-powered design systems to automated manufacturing solutions at a scale that would seem alien to many clinical practices.

This digital saturation makes perfect sense when you consider the economics. Laboratories have much higher rates of digital adoption than clinics. While clinics still debate the ROI of digital transformation, labs have largely moved past that conversation - their focus now is on optimizing and scaling these digital solutions.

Let's dive into the significant announcements and developments from each company at LMT Lab Day 2025. The innovations here offer a fascinating glimpse into where dental technology is headed - and how laboratories are leading the charge in many ways.

Key Industry Trends at LMT Lab Day 2025

3D Printing in Lab Production

If there was one technology that dominated Lab Day, it was 3D printing - but with a distinctly different focus from the clinical show. While the Midwinter Meeting buzzed about chairside crown printing, Lab Day showcased many solutions from simple printers to industrial-scale printing solutions focused on high-volume production.

The sheer number of 3D printing exhibitors was striking, but even more notable was their focus on automation and production efficiency. Multiple manufacturers unveiled solutions for automated print farms, with features like automatic resin replenishment, robotic part removal, and integrated washing/curing systems. This push toward automation reflects laboratories' need to scale up digital production while controlling labor costs.

Digital Dentures are Booming

The explosion in 3D printed denture materials and workflows was impossible to miss at Lab Day 2025. There were multiple new denture base resins released or polyjet 3D printed dentures. The competition in this space has clearly intensified, with major materials manufacturers racing to capture market share in what appears to be a rapidly maturing technology.

What's fascinating is the stark contrast between clinical and laboratory adoption of this technology. While many clinicians remain skeptical about chairside printed dentures, citing concerns about long-term durability and workflow complexity, laboratories seem to have embraced digital denture production.

This split isn't just about scale - it reflects fundamentally different approaches to risk and return on investment. Laboratories, with their controlled environments and standardized processes, have obviously found ways to make printed dentures not just viable but possibly even preferable to traditional methods. The quality control, reproducibility, and production efficiency they've achieved suggest that perhaps clinicians' hesitation isn't about the technology itself, but rather about lack of understanding or the challenges of implementing these workflows in a clinical setting.

Milling Technology's Evolving Role

While 3D printing dominated many conversations, the lab show demonstrated a more nuanced understanding of digital manufacturing. Unlike the clinical show, where discussions often pit milling against printing in an either/or debate, Lab Day reflected a more sophisticated perspective on how these technologies complement each other.

Laboratory professionals clearly understand that it's not about choosing between milling and printing - it's about leveraging the strengths of each technology. High-strength restorations like zirconia crowns and bridges remain firmly in milling's domain, while printing excels at producing models, surgical guides, and increasingly, dentures. This complementary approach was evident in how manufacturers positioned their products - many booths combined both technologies.

The maturity of the laboratory market was particularly apparent in these discussions. Instead of focusing on which technology is "better," conversations centered on optimization: which combination of milling and printing technologies could deliver the best balance of quality, efficiency, and cost-effectiveness for different types of restorations. This pragmatic approach suggests that as digital dentistry continues to evolve, the future lies not in one technology displacing another, but in their intelligent integration.

Here's what caught my attention, in alphabetical order, from each company:

3Shape - Major Software Updates for 25th Anniversary

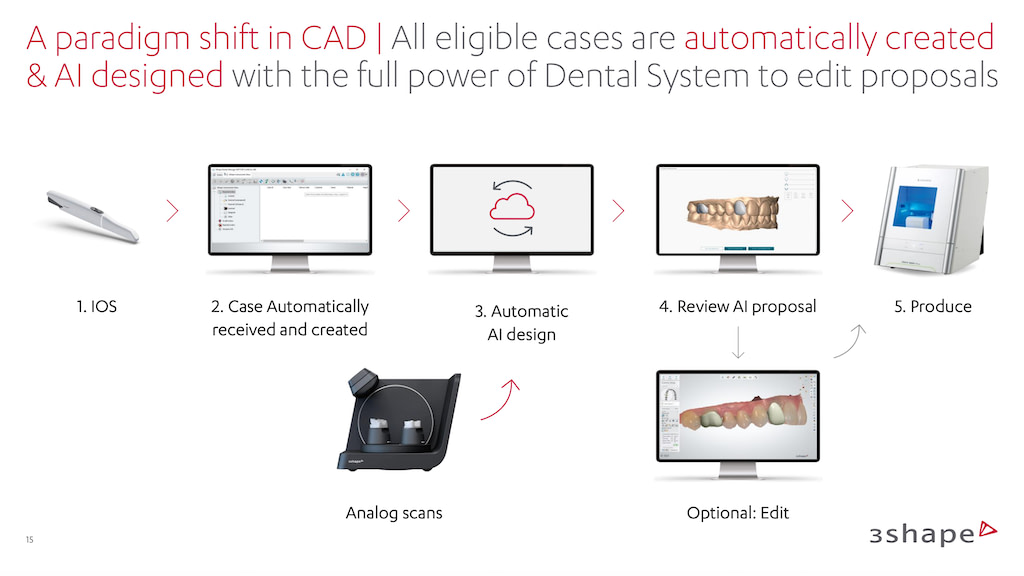

3Shape celebrated their 25th year with major announcements at Lab Day, marking a potential paradigm shift in laboratory workflows through AI integration and automation. Their new Dental System 2024 software introduces a "AI-first" approach where cases automatically enter the lab software and generate complete designs WITHOUT human interaction - fundamentally changing the traditional design process to an "inspect-and-correct" workflow rather than designing from scratch.

What truly sets this system apart from other AI-assisted CAD solutions is its comprehensive automation - everything from margin line identification to final design is handled entirely by AI without requiring any human initialization. This represents the first fundamental shift in CAD workflows in years, as all cases sent to labs can now be automatically AI-designed through 3Shape Automate for crowns, inlays, and onlays. The company indicated this is just the beginning, with expanded automation for additional indications already in development. This level of complete automation marks a pivotal moment in digital dentistry, potentially reshaping laboratory workflows and economics by dramatically reducing design time while maintaining control over final outputs.

3Shape Automate is directly integrated into the workflow and is included for free for 3Shape LabCare subscribers (1600 euro per year), representing a potential leap forward in how laboratories process cases. The system analyzes incoming scans, automatically identifies restoration needs, and generates complete designs that technicians can then verify and modify if necessary. The best part? If you want to change the design, you will be editing the AI designed crown on 3Shape lab software, not a half-baked web browser software. The update brings significant speed improvements beyond just the AI design capabilities, with case management now 10 times faster and case reopening up to 20 times quicker, the company says.

Their laboratory management system also received substantial updates, with improved integration between 3Shape LMS and Dental System to reduce administrative work. The company is also moving away from physical dongles to cloud-based licensing, simplifying software updates and license management.

Full-arch workflows saw improvements through integration with TruAbutment's ioConnect system, and a preview of an upcoming Straumann TRIOS workflow with new exact scan bodies suggests more partnerships are in development.

These updates reflect 3Shape's continued evolution from their early CAD/CAM days to their current position as a major force in laboratory digital workflows - now pioneering what appears to be the next major shift in dental design automation.

Aidite - Expansion into 3D Printing

Aidite, primarily known for their zirconia materials, made a notable announcement at Lab Day with the introduction of their ExPrint-F1 3D printer. This marks a significant expansion beyond their established material manufacturing business into the hardware space.

The ExPrint-F1 represents Aidite's first venture into 3D printing technology, showing how traditionally materials-focused companies are increasingly looking to provide complete solutions. This move by a well-established zirconia manufacturer into the 3D printing market reflects the broader industry trend where the lines between material suppliers and equipment manufacturers continue to blur.

As digital manufacturing becomes the norm in dental laboratories, companies like Aidite are working to secure their position in this evolving ecosystem by expanding their offerings across the digital workflow.

Argen - Manufacturing Giant's Full Portfolio

Like many of the industry's largest players, Argen utilized a dedicated showroom space at Lab Day to showcase their comprehensive range of manufacturing solutions. As one of the world's largest dental materials manufacturers, their substantial presence reflects their deep roots in the laboratory market.

Their expansive room featured their complete portfolio, mills, printers, the works. While no new product announcements were made, Argen's position as a major supplier of both traditional and digital materials to laboratories worldwide was clearly evident in their comprehensive display.

Amann Girrbach - Meet the New Motion 3

Like many major manufacturers at Lab Day, Amann Girrbach took advantage of having their own dedicated showroom space away from the main exhibition halls. This setup allowed them to showcase their complete workflow and solutions in a more controlled environment.

The new release for the company at the show is their new Ceramill Motion 3 milling machine. While it maintains the hybrid wet/dry capabilities of its predecessor, the Motion 3's standout feature is its integrated air compressor - a seemingly simple addition that solves a practical challenge. Not exactly a huge release but an incremental upgrade.

Beyond this quality-of-life improvement, the Motion 3 introduces several automation features aimed at reducing operator intervention. The machine includes RFID tool tracking, automated calibration, and a built-in display for guided maintenance procedures. These features, combined with AG.Live integration for production monitoring, reflect a growing industry focus on workflow automation and remote management capabilities.

Otherwise it was much the same for the great milling company. All their other mills were on show as well like the Ceramill Matron.

Asiga - The Laboratory 3D Printing Standard

If Sprintray dominates the chairside 3D printing conversation, Asiga holds a similar position in the laboratory space. Long considered the gold standard for dental printing, their solutions are deeply embedded in laboratory workflows worldwide. At Lab Day, they showcased their latest innovations, announced concurrently with the Midwinter Meeting, to an audience that has come to expect excellence from the brand.

Their expansion into materials is significant, with three new proprietary resins - a soft night guard material, a flexible denture resin, and an orange tray resin. However, it was their hardware innovations that generated the most buzz.

The Asiga MAX 2's upgrades, including an enhanced heating system and redesigned latch mechanism, have improved an already popular laboratory workhorse. The new 50-micron variant particularly resonated with labs specializing in high-precision work like implant components. Their new crown printing kit, complete with a small-format resin tray, is more focussed for clinics I feel.

The star of their Lab Day presence was undoubtedly their new cure box. Available in two sizes to accommodate different production volumes, it brings several innovations to post-processing. The unit features a quiet vacuum pump for oxygen-free curing, optional nitrogen gas connectivity, and the ability to add a second vacuum pump for faster processing. What particularly impressed laboratory technicians was its intelligent load detection system - the unit automatically adjusts curing parameters based on the number of parts inside, a feature that could prove invaluable in production environments where consistency is crucial.

Atomica.AI - AI solutions for Labs

Present at both Lab Day and Midwinter Meeting, Atomica.AI maintained their momentum in the dental AI space. While no new announcements were made, their AI-driven design solutions found a particularly receptive audience among laboratory technicians who recognize the potential for automation to address growing production demands.

Their comprehensive suite of AI-powered services - from implant planning and stackable surgical guides demonstrates how artificial intelligence can streamline laboratory workflows. In the lab setting, where consistency and efficiency are paramount, their automated design capabilities offer a compelling solution to both the skilled labor shortage and increasing case volumes.

Stay updated and get the latest Digital Dentistry News on Scanners, Mills and 3D Printers.

We Will Email You When We Publish A New Article So You're The First To Know!

BEGO - Resins and RPDs

Unlike their absence from the clinical show, BEGO made a showing at Lab Day. While their TriniQ resins remained a centerpiece of their display, it was their laboratory production services that drew my attention - particularly their removable partial denture framework offering.

They have this interesting partial framework service. At $99 for a finished framework or $89 for a sandblasted-only product, with a 5-day turnaround time, BEGO is essentially democratizing high-end partial metal framework production. This type of service highlights a growing trend in the laboratory industry where even labs with full digital capabilities are outsourcing certain productions to optimize their workflow and manage costs. It is fascinating seeing these services from a clinician point of view.

Otherwise nothing too new here and no new resins.

Bite-Finder - AI Solutions for Occlusion Challenges

Bite-Finder made an appearance at Lab Day, showcasing their AI-powered bite correction software. This solution addresses one of the most persistent challenges in digital dentistry - accurate occlusal registration. As anyone experienced with intraoral scanning knows, capturing precise bite relationships remains problematic with most scanning systems, often not being done properly - labs can attest.

Their software applies artificial intelligence to analyze and correct bite relationships, potentially saving significant time for both practices and laboratories. For labs, this means fewer rework requests, while practices benefit from more predictable results from their digital impressions. This practical application of AI to solve a specific, well-defined problem illustrates how targeted solutions are often more immediately valuable than broader AI initiatives.

The interest in Bite Finder at Lab Day reflects laboratories' ongoing struggle with inconsistent occlusal data from digital impressions. As scan-only workflows become increasingly common, solutions that improve the reliability of this crucial data point become particularly valuable to the digital laboratory ecosystem.

Carbon - New Flexible Partial Material

Carbon maintained a substantial presence at Lab Day, showcasing their established printer lineup, but it was their new FP3D resin that was their big release here. This flexible partial denture material joins the growing space of 3D printed denture solutions, but with some impressive technical specifications.

The FP3D resin's properties are noteworthy - a flexural modulus of 800 MPA, 150% elongation at break, and water sorption of just 1.82 ug/mm3. These specifications suggest Carbon has developed a really solid material. The samples on display looked promising, with good flexibility and aesthetic properties.

The timing of this release is significant, coming amid what appears to be a broader industry push toward printed denture solutions. While many manufacturers at Lab Day were showcasing denture base materials, the flexible partial space represents a particularly interesting niche. Carbon's entry into this market with a material specifically optimized for their printing platform suggests they see significant potential in this application.

DentaFab - New SEGA PRO 4K Printer

DentaFab introduced their new SEGA PRO 4K printer at Lab Day, featuring several technical advancements compared to their last gen printer. The printer offers a 32 micron pixel size with its 4K resolution system, powered by a 385nm wavelength projector.

The SEGA PRO 4K includes practical improvements like a revamped build plate for quicker calibration and a new long-term build tank designed to extend consumable life. Despite its compact footprint (32.5 x 32.5 x 56 cm), the printer offers a decent build volume of 12cm x 6.8cm and achieves print speeds of 90mm per hour at 50 micron layer thickness (the company says). Material compatibility remains a focus for DentaFab, with the printer supporting a range of validated resins through their online material library.

Dentbird - AI Design Solutions Find Their Home

While Dentbird's AOX brand was their priority at the clinical midwinter show, their core AI design solutions found their natural audience at Lab Day. The contrast in their approach to these two markets is telling - while clinicians seek turnkey solutions through AOX, laboratories are more likely to embrace Dentbird's cloud-based AI design tools to enhance their existing workflows.

Lab Day 2025 made it clear that AI-powered CAD solutions are gaining significant traction in the laboratory space, with Dentbird among several players vying for market share. Unlike the clinical show where AI was primarily focused on diagnostics and practice management, Lab Day revealed a robust ecosystem of AI design tools aimed at automation and production efficiency.

The proliferation of AI design providers at Lab Day signals an interesting inflection point in the industry. With multiple companies now offering AI-powered design solutions, we're likely entering a period of market consolidation at some stage where the strongest technologies and most user-friendly implementations will emerge as leaders.

Dentbird's established presence and mature solutions position them well in this increasingly competitive space, but the next few years will be crucial in determining which AI platforms become industry standards.

Dentona - Premium European Resins Gain Traction

Dentona showcased their comprehensive optiprint resin lineup at Lab Day, continuing to build on their reputation for high-quality European-manufactured materials. Their extensive portfolio covers virtually every dental application, from model fabrication and transparent splints to dentures, impression trays, and gingiva masks.

Developed and produced in Dortmund, Germany, these resins have found increasing adoption in North American laboratories looking for high-end materials that work with a wide range of common printer systems.

Dentsply Sirona - Laboratory Portfolio on Display

While no new announcements were made at Lab Day, Dentsply Sirona's presence highlighted their strength in the digital denture space. Their Lucitone Digital Print continues to set the standard for printed denture materials, with its combination of impact resistance, natural aesthetics, and proven clinical performance making it a favorite among production laboratories.

The material's success has made it something of a benchmark in the industry, with many new denture base materials being compared to Lucitone's physical properties and aesthetics. Its integration with multiple printer platforms, including the recent Formlabs validation, shows how this material has become the go-to choice for many laboratories transitioning to digital denture production.

Their broader CAD/CAM portfolio was also on display, but it's clear that Lucitone Digital Print remains one of their most significant contributions to digital laboratory workflows. While new players continue to enter the denture printing space, Lucitone's established track record and clinical success make it the material others aspire to match.

DG Shape - Steady in the Milling Space

Unlike their absence from the clinical show, DG Shape commanded a dedicated showroom at Lab Day, allowing them to showcase their complete milling ecosystem. The spotlight was on their newly upgraded DWX-53D, the latest iteration of their flagship dry milling machine.

The DWX-53D brings several improvements to their proven machine. The company says the upgraded spindle offers 1.5x more tool gripping power compared to the previous DWX-52D Plus, particularly benefiting PMMA applications. Speed improvements are notable too, with up to 20% faster milling times for both PMMA and zirconia. A new "Open Edge Adapter" enables advanced milling beyond 90 degrees, particularly valuable for full-arch cases where complete reproduction of the design is crucial.

Perhaps the most contemporary addition is the built-in webcam for remote monitoring - a feature that reflects the growing industry trend toward remote operation and workflow management. While not revolutionary, these incremental improvements demonstrate DG Shape's commitment to refining their established technologies rather than chasing dramatic innovations.

In a interesting move for a company known primarily for milling, DG Shape also introduced their new 3DX Print system at the show. The printer looks like a white-labeled version of Shining 3D's AccuFab printers, marking DG Shape's first venture into additive manufacturing. This expansion into 3D printing by a traditional milling company reflects the growing importance of having both technologies in modern laboratory workflows.

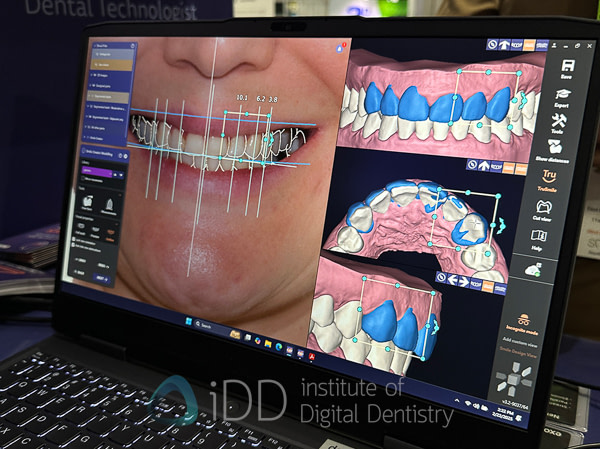

exocad - AI Integration Deepens

exocad, one of the market leaders in CAD, focused heavily on AI integration at Lab Day, introducing several new automated features.

Their new AI Design feature offers automated design suggestions for single-unit crowns, complemented by an AI-powered margin repair tool for fixing problematic scan areas. The new Auto Articulator feature enables automatic dynamic occlusion, and the platform now offers seamless integration with compact milling machines.

The Bite Splint module received automation improvements, including the ability to design splints for both arches simultaneously. The Full Denture module added several features: Copy Denture for quick reproduction of existing dentures, ball attachment design capabilities, and integration with the Ivotion Denture System.

Smile Creator saw substantial updates with new AI services. TruSmile Video and Photo generate realistic smile makeover visualizations, while new features enable virtual gingiva design and smile designs based on natural teeth. The 3D-to-photo alignment system was also improved.

The iTero-exocad Connector is also being improved with broader file sharing between labs and doctors, including images, videos, and X-rays through the MyiTero portal. The new bi-directional communication enables 3D design sharing and margin validation using iTero's intraoral camera and NIRI images.

A new beta feature for post and core design was also introduced, allowing direct design of matching crowns.

These comprehensive updates, particularly the focus on AI-driven automation, reflect the laboratory industry's rapid digital transformation. While AI was once a buzzword, it's now becoming a practical tool for addressing real workflow challenges in dental laboratories. exocad's direction mirrors the broader industry shift toward intelligent automation, where technology isn't just about digital production but about making complex design decisions more efficient and consistent.

Formlabs - Opening Up Their Ecosystem

In a major shift, Formlabs announced that their printers will now support an open material mode. This is big news - Formlabs has historically maintained a strictly closed ecosystem, so the ability to now use any third-party resin represents a fundamental change in their approach to the market. Sign of the times.

Beyond opening their platform, the company has been actively expanding their validated materials list, particularly through collaborations with Pacdent etc. The most significant validation came for their Form 4B printer, which is now approved for use with Lucitone Digital Print - the market-leading digital denture material and a crucial addition for laboratories invested in digital denture production.

This dramatic departure from their closed ecosystem strategy suggests Formlabs recognizes that laboratories need flexibility in material choice. For a company that built its reputation on tightly controlled material-printer validation, this opening of their platform marks a significant evolution in their market approach. I am all for it.

GC - Materials Portfolio Holds Steady

Much like their clinical show presence, GC's Lab Day booth maintained focus on their established product line, particularly their LiSi CAD/CAM materials. The company showcased their proven materials portfolio, including their recent shade additions, but held back on any major announcements.

This conservative approach at both Chicago shows, particularly notable for such a major manufacturer, suggests they may be holding developments for IDS. For now, they continue to rely on the strength of their core laboratory materials, which have earned their place in many labs' digital workflows.

Stay updated and get the latest Digital Dentistry News on Scanners, Mills and 3D Printers.

We Will Email You When We Publish A New Article So You're The First To Know!

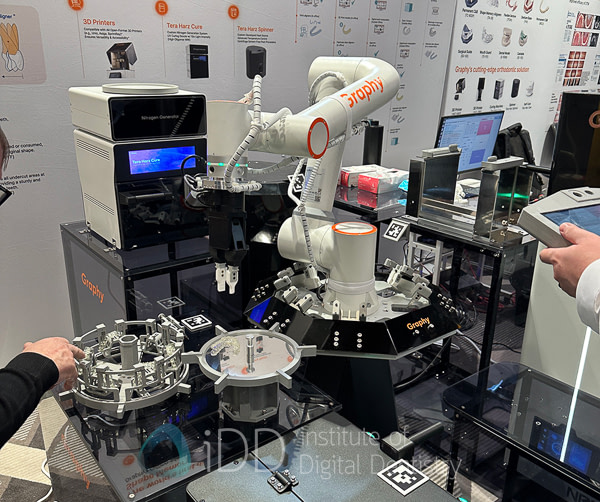

Graphy - Automation Meets Aligner Production?

Graphy's Lab Day presence centered on their aligner materials and notably, their new automated production system. The company demonstrated a robotic solution that manages the entire aligner workflow from printing through post-processing.

This automation system addresses a key challenge in laboratory aligner production, where post-processing often creates workflow bottlenecks. Their robotic approach to handling the complete process could significantly impact efficiency for high-volume laboratories producing hundreds of aligners daily.

The choice to showcase this system at Lab Day, rather than the clinical show, aligns with laboratory production needs. While clinics typically handle small aligner volumes, laboratories increasingly seek automation solutions to maintain quality while scaling production.

Verdict is still out if direct to print aligners really work. If you use it please be in touch! I am hearing mixed things and personally haven't replaced thermoforming aligners after trying a few different resins.

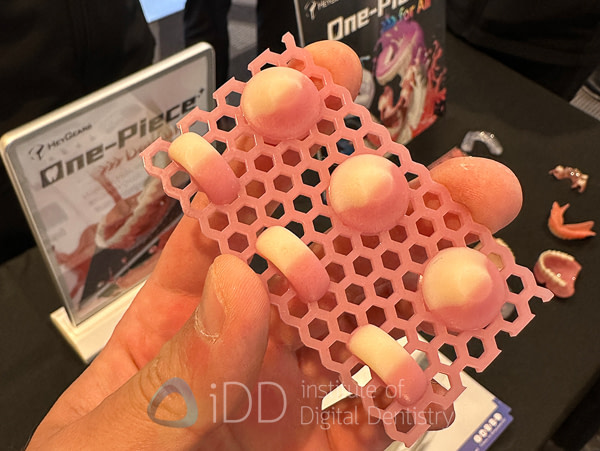

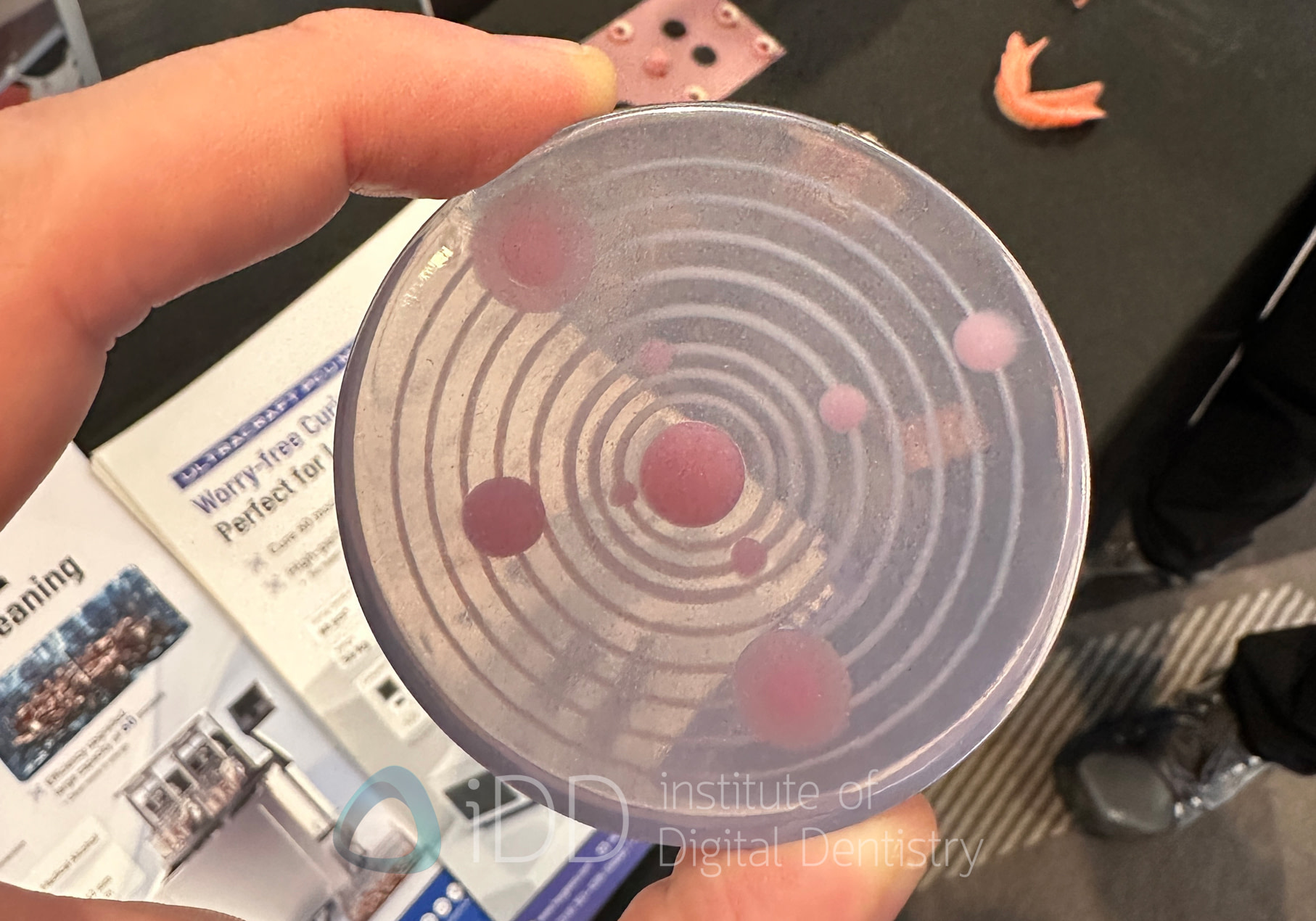

HeyGears - Incredible Rate of Innovation

HeyGears had a large presence at Lab Day, drawing consistent crowds with their comprehensive digital manufacturing solutions. The company's most intriguing preview was their "Multimaterial Fusion" technology - a development that claims to achieve multi-color prints from a single resin using DLP technology. While mainly a technology demonstration with sample discs on display, the concept represents an interesting direction for dental 3D printing.

This multi-color printing approach could have significant implications for dental applications. Though details were limited and the technology appears to be in early stages, it reflects HeyGears' consistent focus on pushing technical boundaries in dental manufacturing.

The scale of their Lab Day presence and the technical sophistication of their demonstrations reinforce HeyGears' position as a major innovator in dental manufacturing. Their track record of turning technical previews into practical solutions makes this multi-color printing development particularly worth watching.

Of course they also had all their popular printers on show for automated printing.

IMES-ICORE - Precision Milling Solutions

Present exclusively at the laboratory show, IMES-ICORE displayed their range of German-engineered milling systems. While no new products were announced, their established lineup of laboratory mills continues to maintain a strong reputation for precision and reliability among laboratory professionals.

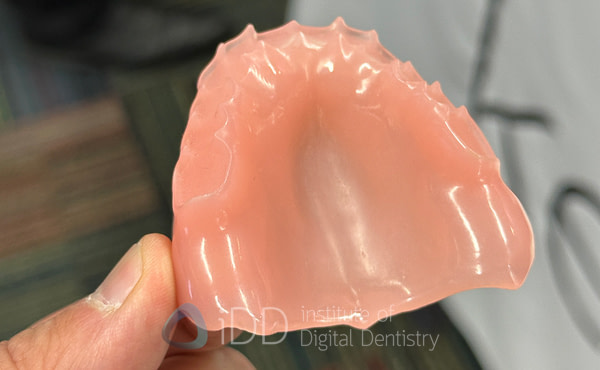

Ivoclar - New Denture Base Resin

Ivoclar had a big booth and of coursed showcased all their great materials and equipment. The new release is their denture base resin. The material had impressive aesthetics and translucency with natural colours.

The resin is validated for both PrograPrint and Asiga systems, and while Ivoclar isn't yet offering printed teeth solutions, the material integrates seamlessly with their existing PMMA and carded teeth options. The printed samples on display demonstrated good fit and finish, particularly at the teeth-base junction when combined with traditional denture teeth.

This release joins the wave of denture base materials launched at Lab Day, reflecting the industry's growing focus on digital denture workflows. Given Ivoclar's reputation in the denture space, their entry into printed denture bases represents another step toward mainstream adoption of this technology.

Currently the market leader in printed dentures is Lucitone Print, it will be interesting to see if this new resin can gain traction in the coming years.

Jensen - Hands-On Education Takes Center Stage

Jensen had a big presence at Lab Day, focusing on practical education. Their booth seemed consistently busy with hands-on sessions, reflecting the company's emphasis on technique and application knowledge.

Their Miyo liquid ceramic system continued to draw significant attention, maintaining its reputation as an exceptional solution for customizing zirconia and lithium disilicate restorations. The system's ability to create highly aesthetic results with minimal thickness has made it a staple in many laboratories' workflows.

Jensen's educational approach at Lab Day highlights an important aspect of the laboratory industry - even as digital technologies advance, developing and refining technical skills remains vital. No new announcements.

Keystone Industries - Another New Denture Base Resin

Keystone Industries, known for their wide-ranging resin portfolio and notably open approach to printer compatibility, launched their new KeyDenture Base material at Lab Day. The high-impact denture base resin joins their successful lineup that includes KeySplint Soft, and continues their tradition of developing materials that work across multiple printer platforms.

Available in four classic Diamond D shades, the material promises high-impact durability while maintaining flexibility. Its low viscosity formulation enables faster printing speeds, and the material has been designed to integrate with popular tooth materials and digital laboratory workflows. The launch of KeyDenture Base, adds to the growing number of denture base materials released at this year's show. No teeth resin either yet interestingly, the focus seems to be all denture bases.

This addition to their portfolio reinforces the broader industry trend toward digital denture production, with material manufacturers racing to provide solutions that match traditional denture materials in both durability and aesthetics.

Lux Creo - Large Production Focus

LuxCreo highlighted their comprehensive dental printing ecosystem at Lab Day, focusing on high-volume manufacturing capabilities. Their distinctive Light Enabled Additive Production (LEAP) technology and Digital Polishing process aim to streamline the production of clear dental appliances, particularly aligners, retainers, and night guards.

The company's approach to 3D printing emphasizes reducing post-processing steps, a significant pain point in dental manufacturing. Their patented Digital Polishing technology claims to achieve 80% higher clarity while eliminating 90% of material waste and 75% of the labor traditionally associated with clear appliance production.

With systems ranging from the chairside iLux Pro Dental to the large-format Lux 3D+, their product line addresses various production scales. The Lux 3D+ is positioned for laboratories and aligner brands requiring 24/7 high-volume production, reportedly capable of printing up to 18 dental models in 35 minutes - less than 2 minutes per model.

Their extensive material partnerships, including Glidewell, Dreve, Keystone, Detax, Pac-Dent (Rodin), and Desktop Health, reflect their open approach to materials. The company's FDA Class II 510(k) clearance for their direct print 4D Aligners and 4D Retainers represents a significant regulatory milestone in the direct-printed appliance space.

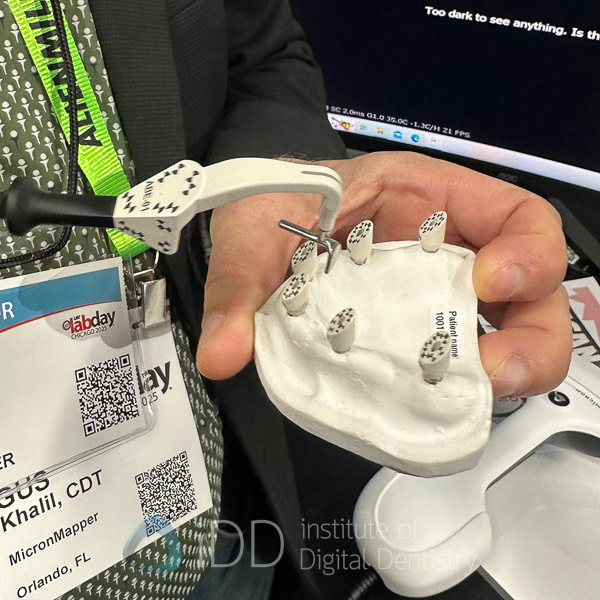

Micron Mapper - Photogrammetry still relevant?

Micron Mapper maintained a substantial presence at Lab Day, continuing to champion photogrammetry for full-arch implant scanning. Their latest innovation, the a ridge mapper, represents an evolution of their technology, to not only measure implant positions but ridge shape in bloody fields when scanners may struggle.

The company's position comes at an interesting moment in the industry. With the emergence of horizontal scan bodies from TruAbutment and intraoral scanner solutions like Shining 3D's Elite, the future role of dedicated photogrammetry systems remains an open question. However, Micron Mapper's focus on speed and ease of use suggests they understand that convenience and workflow efficiency remain critical even as technology approaches evolve, as they deliver one of the fastest photogrammetry capture systems on the market.

It will be fascinating to see what happens in the next 3 years.

NextDent - New Jetted Denture Solution

NextDent unveiled their Jetted Denture Solution at Lab Day, introducing the industry's first multi-material, monolithic jetted denture system. The solution centers around their new polyjet printer, priced around $85,000 from memory, specifically designed for denture production.

What sets this system apart is its ability to print denture base and teeth simultaneously as a monolithic unit using multi-material jetting technology. The company claims a total production time of approximately 10 hours, significantly reducing the manual labor typically associated with denture fabrication. The monolithic nature of the prints eliminates the need for bonding teeth, potentially improving accuracy and durability.

The business case appears compelling for big labs - the system promises minimal material waste, low labor requirements, and high scalability compared to traditional methods, milling, or conventional 3D printing. This technology may represent a significant step forward in digital denture production, offering a glimpse of where large-scale laboratory manufacturing might be headed.

The only other printer using similar tech in the dental lab side is Stratasys.

Pacdent - Popular Restorative Materials

Pacdent maintained a strong presence at Lab Day, showcasing their established Titan and Sculpture resin lines. While no new products were announced, their third-party materials continue to find success in laboratory workflows. I may have heard of some new resins releases are coming at IDS. Keep an eye out.

PIC - Photogrammetry Pioneers at a Crossroads

PIC Dental had a modest presence at Lab Day, a notable contrast for the company that pioneered dental photogrammetry. There is no question about the changing landscape of full-arch digital implant workflows, where their once revolutionary technology now faces competition from multiple directions - other photogrammetry companies, horizontal scan bodies like TruAbutment IO Connect and most recently the Shining 3D Aoralscan Elite.

The company that fundamentally changed how laboratories capture implant positions now finds itself at a fascinating crossroads - and appears to be choosing an unexpected path forward. In a surprising strategic pivot, PIC teased their upcoming "PIC app" - described as "pocket photogrammetry for everyone."

This smartphone-based solution is scheduled for public release on March 28th at IDS 2025, with pre-orders already available at a special limited offer. The promotional materials showed scan flags being captured directly with a smartphone camera and is something that TruAbutment has also teased for the past year as coming to iPads.

This represents a significant evolution for a company built on traditional photogrammetry hardware. PIC appears to be responding to the market pressure and democratizing access to their technology while dramatically lowering the barrier to entry - potentially addressing cost concerns, simplifying workflows, and expanding their market reach.

The timing is strategic, as the dedicated photogrammetry approach that PIC championed faces mounting challenges from an increasingly competitive market. Notably absent was Imetric from Lab Day, suggesting further shifts in this segment of the market.

Despite these challenges, PIC's continued presence and this bold new direction demonstrate their commitment to remaining relevant in the field they helped pioneer. The coming years will likely determine whether this smartphone-based approach can actually be pulled off. Their IDS 2025 launch will be one to watch closely.

Rapidshape - Industrial-Scale Production Solutions

Rapidshape had a significant presence at Lab Day, displaying their range of printing systems. While they showcased small to medium-scale systems for laboratory production, the company's technology powers some of the largest dental manufacturing operations globally, particularly in the clear aligner industry.

This dual approach allows Rapidshape to serve both traditional production laboratories and the growing industrial-scale dental manufacturing sector. Their systems are engineered for reliability and continuous operation, with features designed to withstand the demands of both production laboratory and full industrial settings.

Rapidshape's position in the market illustrates the increasingly diverse scale of dental manufacturing - from small laboratories to massive production facilities. As the dental industry continues to see both consolidation into larger operations and specialization in smaller labs, equipment manufacturers like Rapidshape are developing systems that can serve multiple segments of this evolving landscape. No new announcements.

Stratasys - Leaders in Multi-Material Printing

While Stratasys had no major announcements at Lab Day, their multi-material printing technology continues to stand out in dental manufacturing. Their PolyJet systems remain unique in their ability to simultaneously print multiple materials with different physical properties and colors in a single print. Their ability to print in full color with varying translucencies and material properties in a single print job demonstrates capabilities that go beyond conventional 3D printing approaches.

TruAbutment - Full Arch Solutions

TruAbutment maintained presence at both Lab Day and the clinical show, with their recently announced 3Shape collaboration. They showcased their comprehensive range of milled implant solutions at Lab Day, alongside their scanning technologies. The company's established position in implant component manufacturing was evident in their display of custom abutments, bars, and full-arch frameworks. Nothing new at this stage.

Stay updated and get the latest Digital Dentistry News on Scanners, Mills and 3D Printers.

We Will Email You When We Publish A New Article So You're The First To Know!

VHF - Laboratory Milling Solutions

VHF displayed their complete laboratory milling lineup at Lab Day, including their aligner trimming systems. While no new products were announced, their range of German-engineered milling solutions continues to serve as reliable workhorses for laboratory production.

VITA - Expanding Digital Material Portfolio

VITA's Lab Day booth highlighted their expanding range of digital materials, with particular focus on their multi-layered zirconia and newer 3D printing materials.

The introduction of their denture base resin and teeth resin marks VITA's deeper commitment to the digital denture space, leveraging their long-established expertise in removable prosthetics.

Their multi-layered zirconia continues to build on VITA's reputation for accurate shade matching and natural aesthetics. The material's graduated translucency and color transitions aim to deliver restorations that closely mimic natural dentition without requiring extensive characterization.

VITA's entry into printable denture materials represents an important industry development. As a company with decades of experience in traditional denture teeth production, their move into digital denture materials brings valuable expertise to this rapidly evolving sector. This expansion reinforces the broader industry trend toward complete digital denture workflows, with established materials companies bringing their traditional knowledge into the digital space.

Many other honorable mentions

Walking the two exhibition halls of Lab Day, it becomes clear that covering every innovation and manufacturer is nearly impossible. The sheer number of companies pushing boundaries in laboratory technology is staggering - from 3D printer manufacturers and resin developers to zirconia innovators and AI solution providers. There are even some really fascinating solutions for post-processing like "AutoFinish" systems that automate what has traditionally been highly manual finishing work.

The laboratory landscape is evolving rapidly, with digital workflows becoming increasingly sophisticated. Every corner of the show featured companies working to automate and streamline different aspects of laboratory production. New printer manufacturers are entering the market with specialized solutions, material companies are developing innovative resins and ceramics, and software providers are leveraging AI to tackle design challenges.

An interesting dynamic at Lab Day was the presence of intraoral scanner manufacturers. Companies that traditionally focus on the clinical market were actively showcasing their scanning solutions to laboratory professionals. This reflects the evolving role of dental laboratories, many of which now serve as technology distributors and digital hubs for the practices they support. Labs increasingly purchase scanners to either sell to their client dentists or to provide as part of comprehensive digital solution packages. This relationship benefits both parties - laboratories secure digital impressions that integrate smoothly with their workflows, while practices gain access to digital technology with expert support from their trusted lab partners.

One of the most fascinating innovations on display was BMF's UltraThineer™, described as the world's thinnest cosmetic dental veneer. This product, developed using Projection Micro Stereolithography technology, creates veneers just 100 microns thick - approximately three times thinner than traditional milling options. These 3D-printed zirconia veneers require little to no tooth preparation, potentially transforming cosmetic dentistry by making the process minimally invasive while maintaining strength and aesthetics.

This level of micro-precision manufacturing points to an emerging frontier in dental technology, where additive manufacturing moves beyond simply replacing traditional methods to enabling entirely new treatment approaches that weren't previously possible. As these ultra-precision technologies continue to develop, we may see more applications that fundamentally change clinical procedures rather than just digitizing existing ones.

Final thoughts

Lab Day 2025 painted a clear picture of where dental technology is headed. The laboratory space continues to lead digital innovation in dentistry, with automation and AI integration now moving from concept to reality. While the clinical side of dentistry often grabs headlines with chairside solutions, it's in laboratories where these technologies are being pushed to their limits and refined.

The increasing prevalence of AI solutions at this year's show was particularly telling. From automated design tools to production optimization software, artificial intelligence is no longer just a buzzword but a practical solution to real challenges. This shift comes at a crucial time as laboratories face increasing case volumes and ongoing workforce challenges.

What's particularly fascinating is how the industry has evolved from the early days of digital dentistry. No longer is it about simply replacing analog workflows with digital alternatives - it's about reimagining what's possible in dental manufacturing. The combination of AI-driven design, automated production systems, and new materials is creating possibilities that would have been unthinkable just a few years ago.

Looking ahead, the laboratory industry appears poised for another leap forward. The integration of various technologies - from AI and automation to new materials and manufacturing methods - suggests we're entering an era where dental laboratories can achieve unprecedented levels of efficiency and consistency while maintaining the artistic excellence that defines the profession.

Thanks for reading.