Phrozen have been a massive success story in the world of 3D printing. Since bursting onto the scene in 2016, they have established themselves as one of the world’s most innovative 3D printing companies.

From humble beginners as a group of 3D printing enthusiasts, they’ve built a world-wide community and utilized Kickstarter campaigns to expand into the United States, Europe, Japan, and South Korea, and more. They service a wide range of industries, including jewelery, the digital model community and of course, dentistry.

On our recent trip to IDS 2023, we caught up with Phrozen’s CEO and Co-founder, Ray Wu. You can watch the entire interview below, or enjoy the transcript.

Hi Ray! Can you tell us about your growth and why you chose LCD as your base technology?

Actually, in the past we started with DLP printers. At that time, we thought DLP could be the end solution for resin 3D printers. But at the end of 2016, we found out about LCD, we dived into studying the technology and we found there is a lot of space for LCD printers.

The only thing we needed to do was optimize the optical part and LCD itself so that you can make this printing technology, and catch up with DLP and laser 3D printers.

And then in 2018, we had to make a critical decision, we invested in developing our own LCD printer. Nowadays, we call it Mono LCD. This LCD can largely improve the lifetime of the LCD itself and also improve the printing speed of the LCD 3D printers. And with this Mono LCD, we can catch up with each resin 3D printing technology like DLP and laser.

So, it makes LCD 3D printers a real thing.

Do you think the Mono LCD has a lot longer lifespan because it's just switching from white to black instead of the RGB?

Yes, Mono LCD itself only has white and black, and we make sure all these components have high efficiency in terms of the optical engine.

Does that help with cooling the LCD as well?

Yes, it does help! We also consider the heat dissipation in our LCD. In the past, people always would think their LCDs have just stopped working. That is because of the reaction heat. But for us, we increased the top glasses and also heat dissipation design so that the lifetime of our LCD can improve up to around 5,000 hours.

Tell me about the history of when you started to do more work in the dental industry and transitioned from just a resin consumer printer.

Well, at the beginning we were focusing more on the hobby market and also the jewelry market. At that time, jewelry was our top priority. We tried to make printed parts as fine as possible and also as accurate as possible because of industrial requirements. But back in 2019, I had a lot of requests from the IDS show, and a lot of people requested very accurate 3D printers.

Those people tested our printers and found our printers very accurate. It can print very good results, is very accurate, and also our design is solid. So, many people gave us an opportunity to test with their digital dentistry workflows. And then we were endorsed by lots of dentists. At that time we realized that maybe we need to look into the dental industry more and see what we can do for this industry.

That’s why we decided to step more and more in dentistry.

How many resins do you have validated for your printer?

I think we have more than 40 resins validated with our printer, including some resins from the United States, Europe, and also from Asia.

We mainly focus on surgical guides, temporary crown resins, and also some model resins because of orthodontic demand.

Are you coming out with a new printer later in the year?

Yes! It’s coming in mid-2023.

Actually, we will release our next-generation LCD resin Studio Printers. It takes us one year to collect all of our user's requirements and people always demand speed. They always want to be able to print dental models within 10 minutes. That's how we start. We try to build high-speed LCD resin printers that can finish all their jobs within 30 minutes.

That's our major target.

I noticed that you have what looks like some early prototypes of curing and wash units.

Yes, for dentistry, 3D printing is only one of the processes. We still need to wash carefully following the FDA’s process and also cure completely to make the in-mouth application to be safe enough.

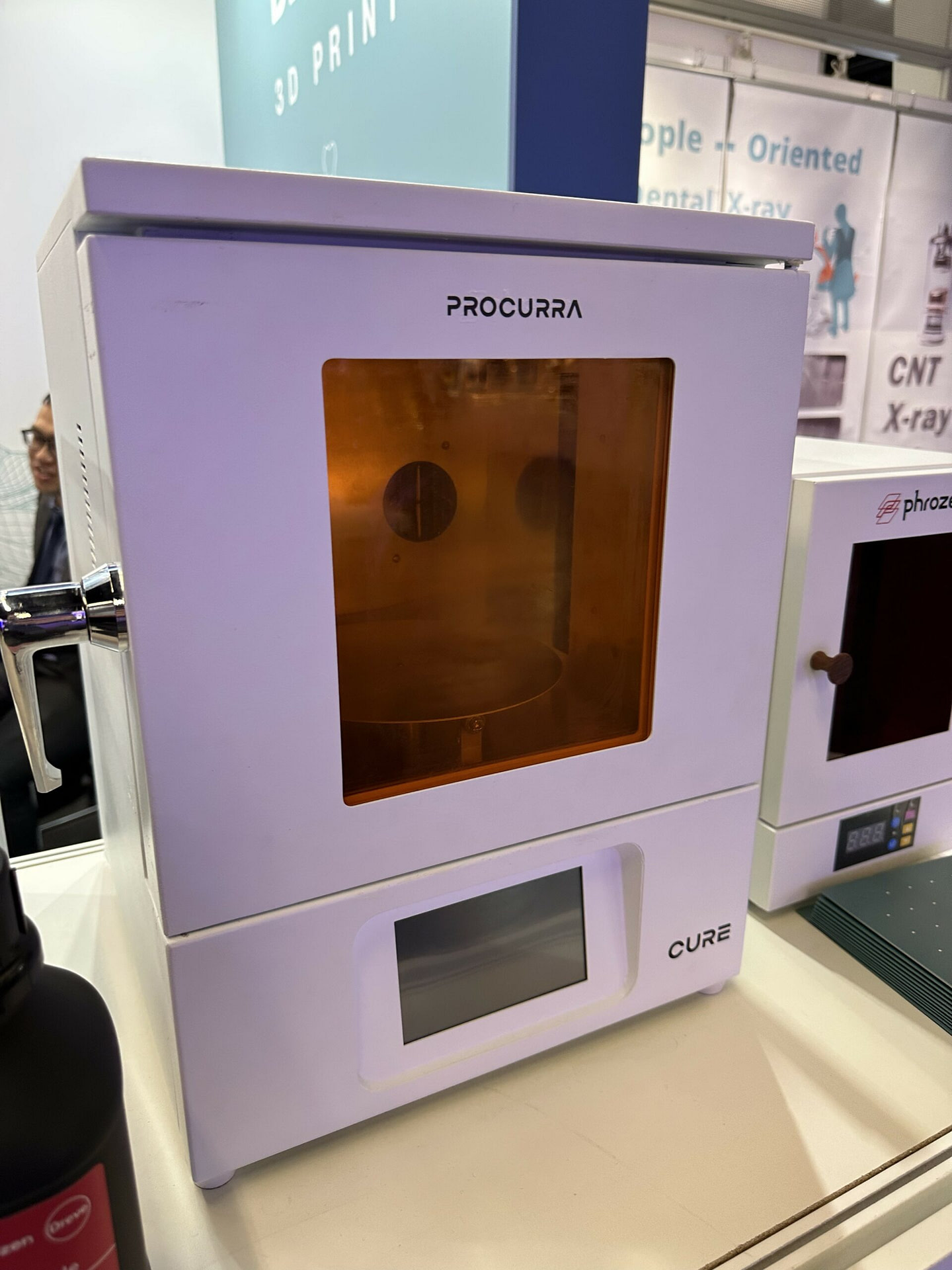

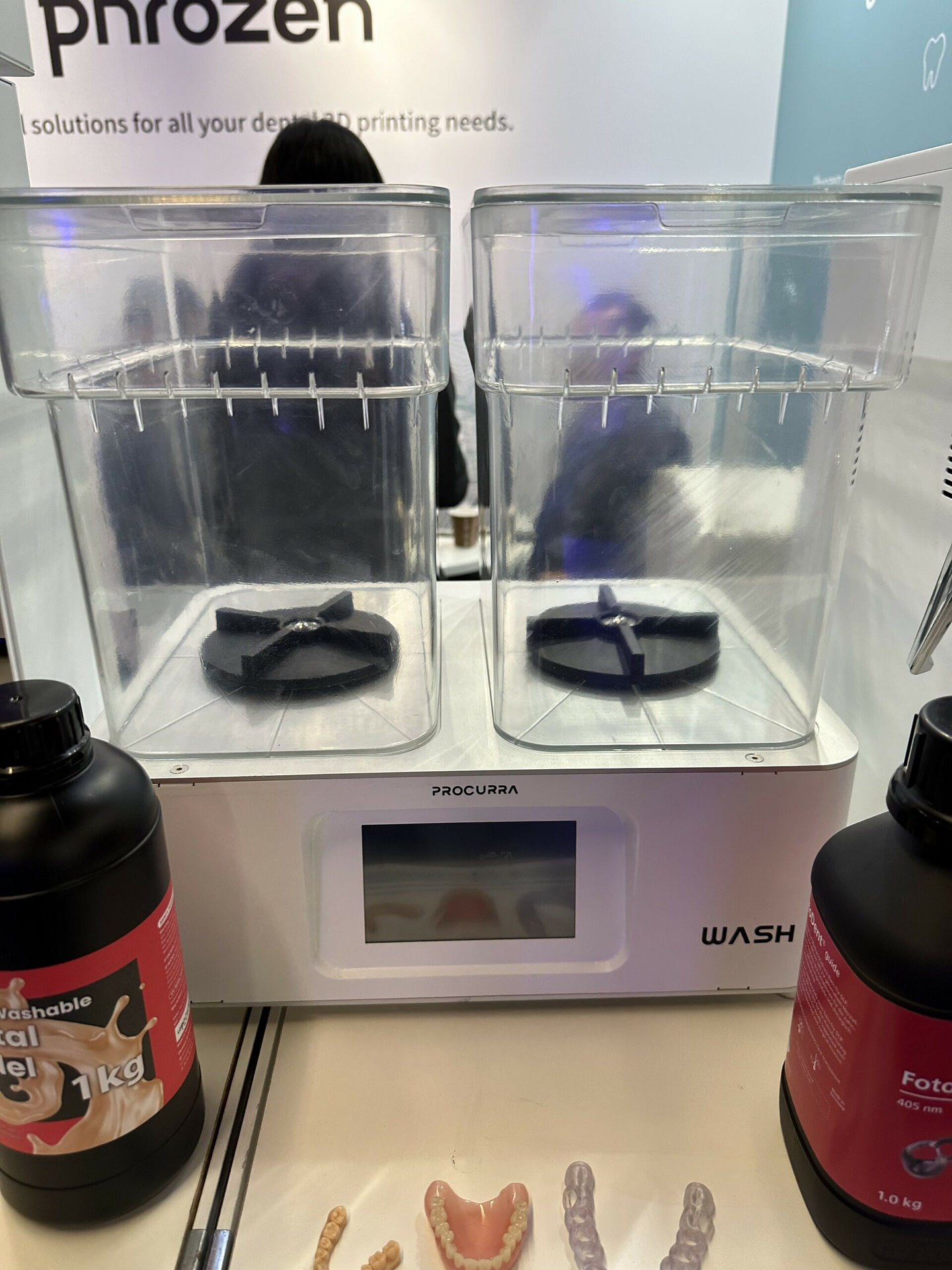

So now we have got our Pro Wash, which has a two-station wash and automatic setup with 40 resins we validated. And also we have a curing unit, that has a heating function where you can put the nitrogens during the curing so that you can cure your parts completely.

That's our post-process unit. Pro Cure and Pro Wash. It will be announced in the middle of May.

Phrozen's Pro Cure and Pro Wash machines.

Are they planning to come out with the next-generation printer?

Yes, it will come out with a next-generation printer. After all, we hope we can provide a total solution to all our customers, not only the printer itself.

Is there any news on the software front? Are there any developments there?

Yeah, we also put a lot of effort into our software development, especially on Slicer. We try to optimize the way we added support and the way we handle the raw data from intraoral scanners.

So, integration with the scanner and scanner software and design software is our key goal in our Slicer development. And also we are adding some cloud functions to let you back up and update your resin profile, in a timely manner so that you can get an updated profile from time to time.

Is there a special integration with Medit scanners or it doesn't change no matter what scanner?

We have officially integrated with Medit, so it can work with Medit's app and also Medit's designing software. So the total workflow is highly integrated. You can directly transfer your file from a Medit scanner to our Slicer without any problem.

Okay, so have a look in your Medit Box, inside Medit Link and you'll be able to find the Phrozen App.

Yes, IDS 2023, this is our first time joining this big show, and we hope more and more people will get to know us not only from the consumer end but from the dental end as well. We want to deliver all of our R&D results and also our product benefits, for our partners and also users.