Until a couple years ago, CAD/CAM technology was the latest advancement in dental technology. Although CAD/CAM is still used extensively as a crucial tool in dentistry today, 3D printing has become a digital revolution that the dental industry has quickly adopted, in both chairside and in dental laboratories.

In recent years, 3D printing has proven to be a more efficient and cost-effective system to embrace an in-house workflow. Dentists, dental technicians and dental assistants can produce custom-made dental appliances, from printing orthodontic aligners and implant models to surgical guides and crowns. More accurate and highly-detailed appliances can be produced in a fraction of the time it would if using traditional, conventional methods.

We first started reporting on 3D printing in dentistry over three years ago - and now it looks like the era of the 3D printer is well and truly upon us.

So, we thought it was time for a much-needed update on 3D printing and 3D printers.

But first, let’s go over the definition of what exactly 3D printing is in relation to digital dentistry.

What is 3D Printing in Digital Dentistry?

The definition of 3D printing or additive manufacturing as defined by the American Society of Testing and Materials is “the process of joining materials to make objects from 3D model data, usually layer upon layer”. So as an additive manufacturer of three-dimensional appliances, it can be used for a large range of different applications in dentistry, including but not limited to:

Study and smile design models

Surgical guides for implant placement and periodontal surgery

Bite splints and night guards

Clear aligners

Fabrication of removable prosthetics such as dentures

Custom trays

Provisional restorations

The term additive manufacturing includes many types of 3D printing technologies where the most commonly used technologies in dentistry are selective laser sintering (SLS), material jetting (MJ), stereolithography (SLA), and fused deposition modeling (FDM).

Our 2020 blog article “3D Printing in Dentistry - Technology Overview and Options” goes into more depth about all the different technologies if you’d like some more detail.

As the key patents of 3D printing technology expired ten years ago in 2013, the market has since seen exponential developments in 3D printing technology being available to consumers at increasingly competitive prices. Now there is an extensive range of printers available to meet the needs of different dentists and clinics, ranging from inexpensive individual printers to more industrial printing ecosystems.

Latest Updates on 3D Printing Technologies

The rise of intraoral scanners has been a major catalyst for the growth of the 3D printing market in dental laboratories and clinics. Looking at all the latest 3D printers, printing resins, and technologies present at IDS, it's clear that different clinics and dentists have different requirements from their 3D printers, so there's a wide range of technology available that have their pros and cons. Different technologies have allowed printers to advance extremely quickly.

Open vs. Closed System

All digital systems on the market can accept an STL file, but open and closed systems in 3D printing are different from milling systems. All printers are open, but some printer manufacturers only use resins that they have validated and are confident in its printing compatibility, to ensure successful outcomes. As a lot of time and money is dedicated to validate certain printer resins to follow strict protocols for patient application, some 3D printing systems should follow these validations and processes.

Biocompatible Materials

New biocompatible materials specifically designed for dental applications have been developed alongside the advances in 3D printing technology. These materials can have different local certifications, such as FDA, TGA, CE certified, that mark it safe for use in the mouth, allowing for the production of functional and durable dental restorations.

Integrated Workflows

With improved interoperability between other areas of digital dentistry such as intraoral scanners, computer-aided design (CAD) software and computer-aided manufacturing (CAM) systems, further integration of 3D printing into digital workflows can be achieved. The production process can be streamlined and completely digital to improve the overall efficiency of dental workflows, namely in-house.

Chairside 3D Printing

Chairside 3D printing has now become a viable alternative in dental clinics as opposed to outsourcing work to a dental lab. As options for 3D printers range from large-scale industrial printers to smaller desktop printers, chairside 3D printing allows for same-day production of dental restorations thus eliminating the need for multiple appointments and reducing patient wait times.

Customized Dental Implants

Using patient-specific data, 3D printers allow for the creation of highly customized implants. These 3D printed implants are commonly implant abutments, made of titanium or biocompatible materials which are then used to attach a crown or bridge to the patient's jaw. The production of these dental implants means that they perfectly fit a patient’s anatomy, can accurately mimic the patient’s teeth, improve implant placement and better patient comfort and clinical outcomes.

Surgical Guides

Surgical guides can be 3D printed to use during implant placements, jaw surgeries and other complex dental procedures. Much like customized dental implants, these surgical guides are designed using patient-specific data and allow for precise and minimally invasive surgical procedures, reducing risks and improving outcomes.

Digital Dentures

Advancements in 3D printing have led to the possibility of creating dentures digitally. Digital dentures are created using scans of a patient’s mouth, where this data is used to design the denture and then 3D printed. As a more accurate, comfortable and efficient alternative compared to conventional heat- or self-cured dentures, improvements to patient care and comfort, faster turnaround times and improved clinical outcomes are the benefits to this custom development.

Digital Wax-Ups

The usual method of traditional wax-up restorations used for prosthodontic treatments can be done digitally. Digital wax-ups can now replace traditional wax-ups using 3D printing to be more accurate, faster and cost-effective, allowing for better communication between dental laboratories and clinicians.

Dental Insurance

With more 3D printed resin crowns being produced as a result of the rapid advancements of 3D printing technology and additional printer resins entering the market, the application and longevity of different dental appliances remains to be seen. As of January 1, 2023, dental insurance companies updated their CDT coding (a set of medical codes for dental procedures that cover oral health and dentistry) to allow for 3D-printed resin crowns to be reimbursed as permanent crowns within the American market.

Dental Education and Training

Dental schools and training institutes have started to incorporate 3D printing into their curriculum to prepare future dental professionals - dentists, dental technicians, dental assistants etc. - for the future of digital dentistry.

As part of iDD’s commitment to making digital dentistry accessible to everyone, you can purchase our online 3D printing and design course bundle on our website, which you can get lifetime access to so you can refer back whenever you want.

3D Printing at IDS 2023

iDD recently visited numerous booths at the International Dental Show (IDS) in Cologne, Germany - the world’s leading trade fair for the dental industry. There were many improved printers and a heap of new releases as well, so here’s a short overview of all the 3D printers and printing technology we saw at IDS:

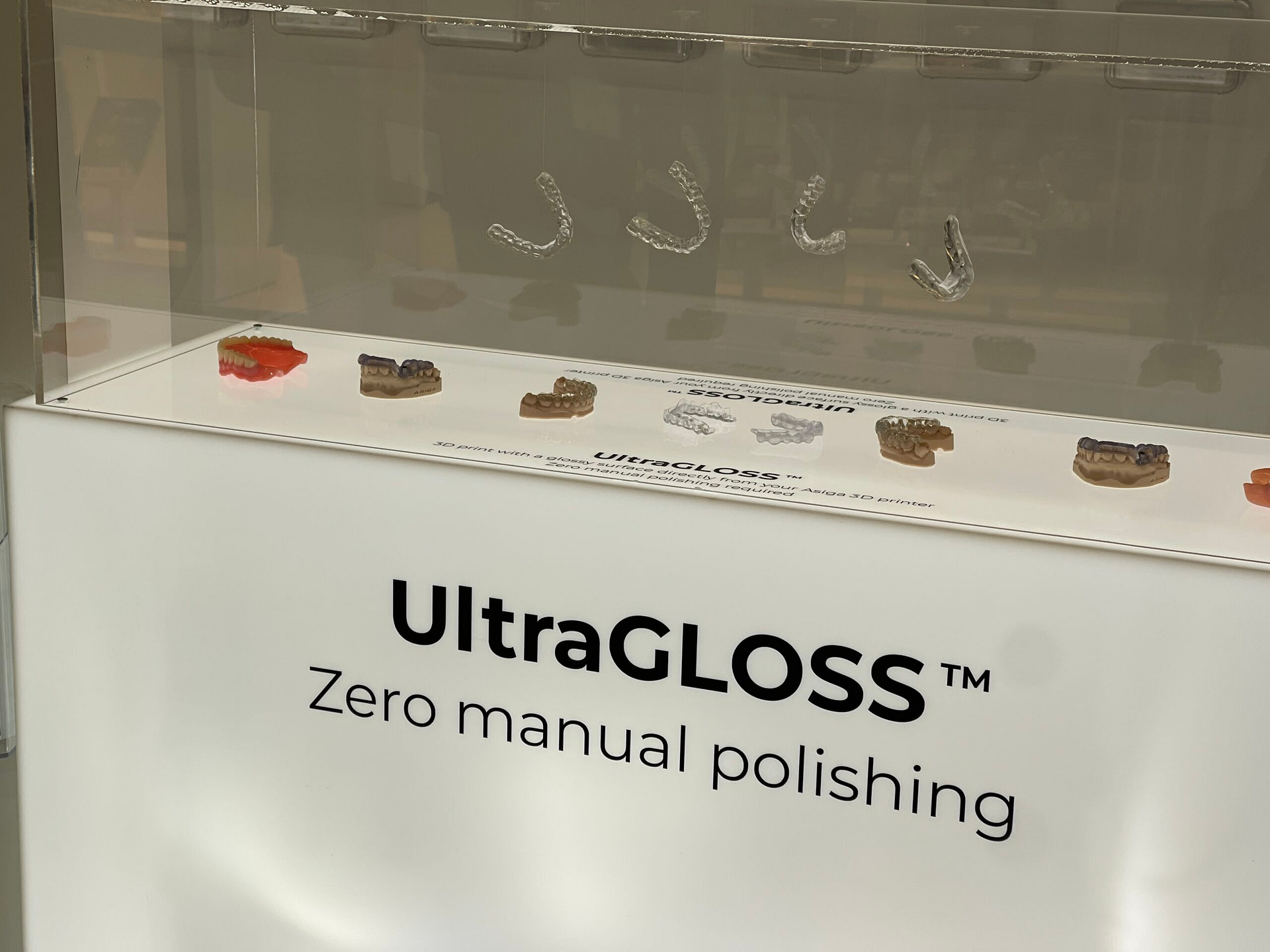

Asiga UltraGLOSS

Asiga introduced new UltraGLOSS material, used for dental occlusal splints, clear earmoulds/earshells, lenses and visors. This clear material doesn’t require any special post-processing when directly 3D printing clear parts as it does so with a pre-polished surface.

UltraGLOSS material trays on display at the Asiga booth at IDS 2023

DentaFab Printing Resins

As a company that produces all their products under the same roof - printing materials, software, hardware - DentaFab is in the process of certifying their 3D printing resins as biocompatible globally. As an organic chemical, DentaFab’s biocompatible printing resin is currently TGA (Australia), CE (New Zealand) and FMA (Japan) certified whilst MDR (Europe) and FDA (USA) certifications are ongoing.

Desktop Health Einstein Pro XL

A DLP-based polymer printing system that Desktop Health released, the Einstein Pro XL, is said to be up to 50% faster than their previous printers. With an accuracy of 45 microns in X and Y over a large build area and includes hyperprint technology to further reduce print time.

Desktop Health's Einstein Pro XL on display at IDS 2023

Heimerle + Meule FilaPrintM

A 3D desktop printer, FilaPrintM, was on display from Heimerle + Meule which featured an integrated camera for optical control from the workplace or from home (through a cloud solution), two print heads to enable two-colour prints in one work step (pink/tooth-coloured), a drive belt which allows for efficient 24/7 printing without a break and more.

Two colored printing filament for Heimerle + Meule's FilaPrintM

NextDent LCD1

NextDent is known for their NextDent 5100, a high speed DLP printer but they recently released the LCD1. A small desktop printer with LCD technology, the LCD1 uses all the same printing resins as the 5100 as well as their latest castable resin, CastBlue, but is also an open system.

Phrozen Studio Printers

Similarly to NextDent, Phrozen announced that they would be releasing their next generation LCD resin Studio Printers in mid-2023. A supposedly high-speed LCD resin printer that can finish jobs within 30 minutes, based on all the feedback they’ve received from their user’s requirements.

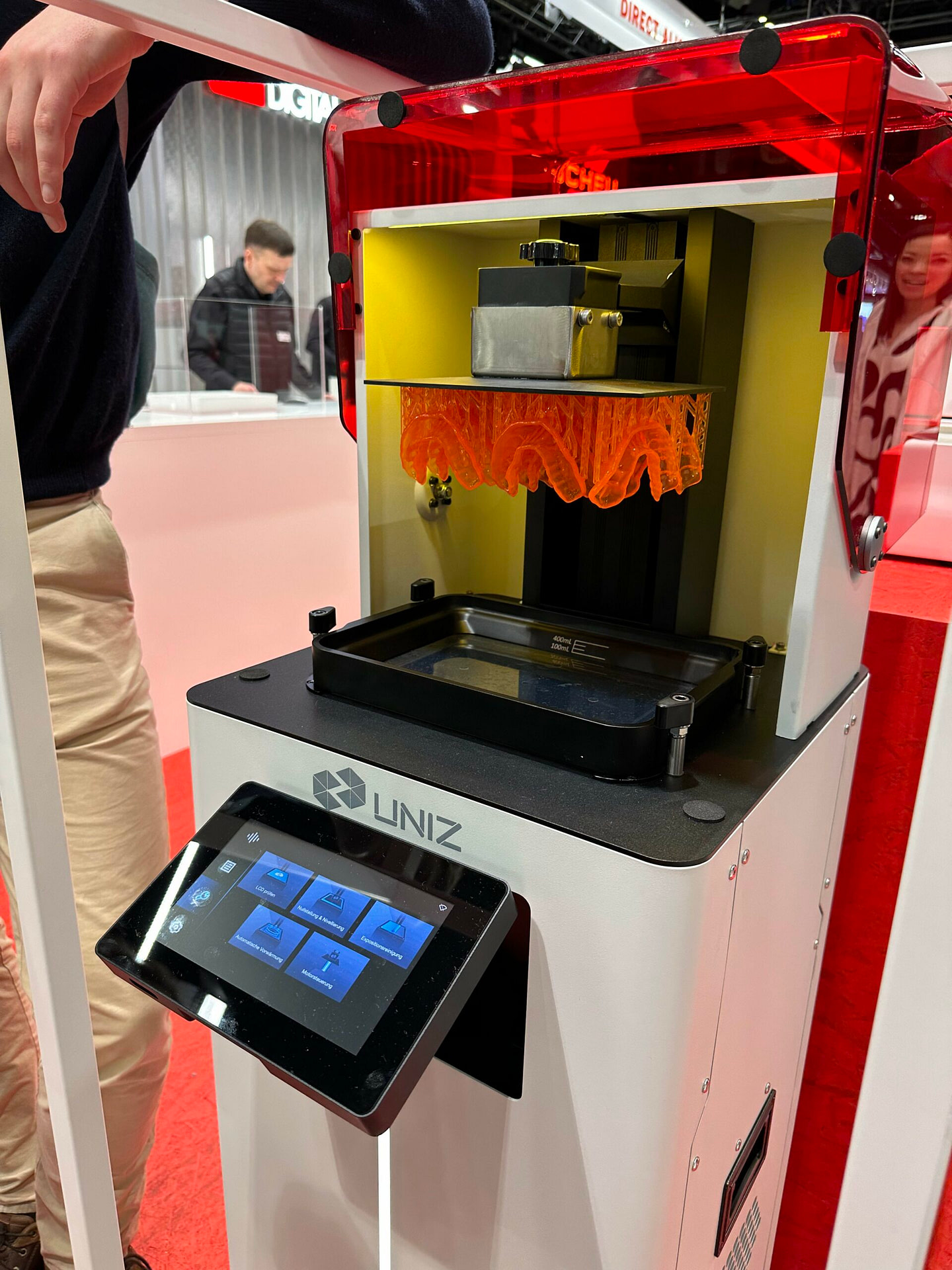

SCHEU Uniz NBEE

Claimed to be the world’s fastest resin 3D printer, the Uniz NBEE is an LCD 3D printer that was specifically designed for the dental industry for high quality outputs. With a build speed of 280 mm/h, this printer can print 6 dental models in just 5 minutes and includes an anticoll high performance server to enhance print precision.

Uniz's fastest LCD 3D printer, the NBEE

SprintRay Pro S Crown Kit

As one of the leading companies at the forefront of the 3D printing revolution in digital dentistry, SprintRay launched their latest product, Pro S Crown Kit. A 3D printer which can print six crowns in less than 15 minutes with those crowns being made from ceramic resin.

Conclusion

The possibilities with 3D printing in dentistry are endless. Now more than ever, dentists are implementing 3D printing technologies in-house due to the efficiency of its turn-around time and overall accessibility.

With a plethora of dental companies and brands competing in a saturated market of 3D printing systems, it isn’t that difficult for any dental professional to find one based on their personal and/or patient treatment requirements.

Although equipment, materials and services differ with 3D printing technologies, new and innovative applications of 3D printing in dentistry still have room for further exploration. As with every other industry utilizing digital technologies within its field, digital dentistry and 3D printing will only continue to evolve striving to improve patient health and care, increase efficiency and ROI and enhance treatment outcomes.

We can expect, as technology continues to advance, for 3D printing to play a significant role in transforming the field of dentistry.

The advancements in 3D printing technology discussed in this article highlight a transformative shift toward more innovative and personalized dental care. At Ambulatorio Recchia, our dental practice in Verona, Italy, we are fully committed to leveraging cutting-edge solutions to enhance patient outcomes.

For our elderly patients, we focus on using surgical splints to improve comfort and functionality during dental implant procedures. For children, we emphasize the importance of custom-made mouthguards for optimal fit and protection. In orthodontics, we rely on aligners to provide precise and aesthetically pleasing solutions, while in aesthetic dentistry, we utilize emotional mock-ups to help patients visualize their ideal smiles before treatment begins.

The precision and efficiency enabled by 3D printing align seamlessly with our mission to deliver forward-thinking, patient-focused care. We are excited to continue integrating these innovative technologies into our practice in Verona, Italy.