As we enter an explosive new era in dentistry, the digital revolution is fundamentally changing the landscape of the profession.

No longer is there a need for traditional impressions using alginate or polyvinyl siloxane (PVS) materials to produce plaster casts. Today's dental professionals have advanced tools such as intraoral scanners (IOS), computer-aided design and computer-aided manufacturing (CAD/CAM) technology, and 3D printing at their disposal.

These new technologies are transforming dental restoration fabrication and the patient experience. But, navigating through this digital transformation is not without its complexities.

All scanners these days have an ‘open architecture’ to allow for scans to be exported and sent to dental laboratories. Labs use third-party CAD software to preview the received STL, PLY, or OBJ files and create restorations based on these scans.

So, it’s essential to save and select the correct file format when exporting and sending it through an order form if outsourcing to a lab.

Depending on the scanner you use to capture your intraoral scans, different file formats can be exported to represent the 3D models of dental structures. These scans are usually exported in three formats - STL, PLY, or OBJ files.

So, what are these formats, and why do they matter? Which format should you choose when exporting your scans?

Understanding the distinct characteristics, strengths, and weaknesses of these formats is not only aimed at digital dentistry newcomers but also at seasoned professionals who are looking to enhance their understanding of these file formats.

In this comprehensive article, we'll dive deeper into the world of digital dentistry file formats, exploring how STL, PLY, and OBJ files function, what separates one from another, and why choosing the right one is crucial in creating a connection between dental practitioners and laboratories.

By the end of it, you'll be able to confidently select the correct file format that aligns best with your digital workflow, and further elevate the level of care you provide to your patients.

STL (Standard Tessellation Language)

STL, or Standard Tessellation Language, is the most commonly used file format in digital dentistry. Their mono surface recordings make it universally compatible with CAD/CAM equipment and software across the entire industry.

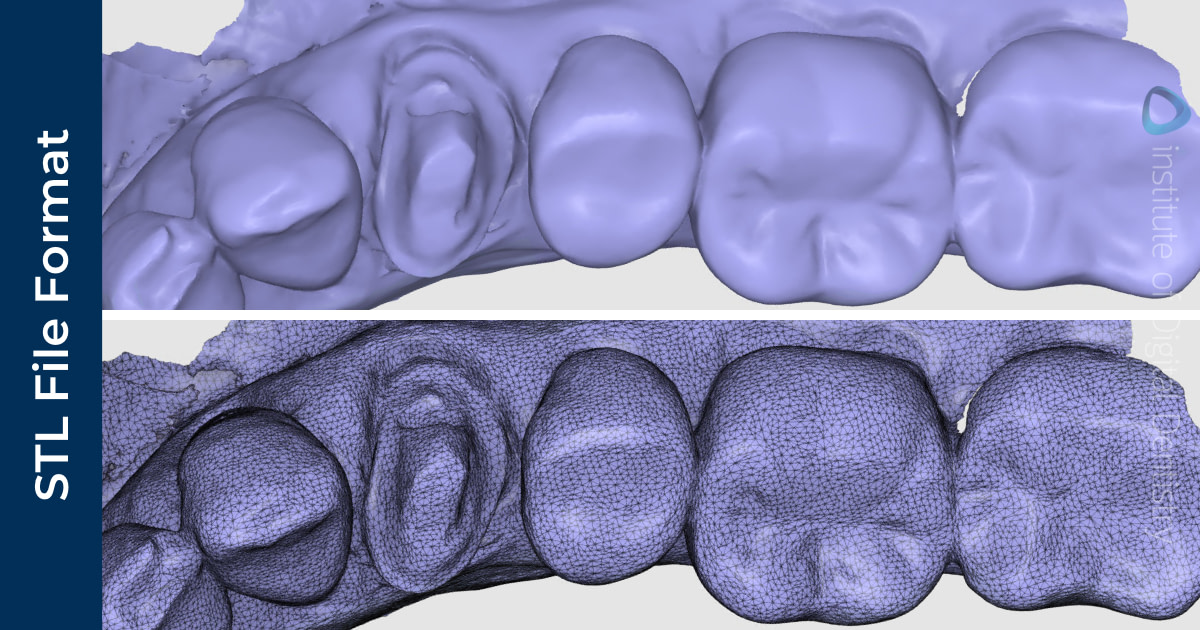

The 3D models of STL files are generated via the intraoral scanner. This scanned surface is represented as a mesh of triangles, each triangle defined by three vertices (points in 3D space that define the shape of the object) and a normal vector.

The complexity of the case, the IOS software, and the resolution of the scan can require more or fewer facets (triangles within the tessellation) to cover the 2D surface of the scan. As a result, typically the more basic and flat the scanned surface of the object is, the STL is represented by lesser, larger triangles whereas a more complicated and irregular surface is represented by smaller and more numerous triangles.

STL files can be saved as full-size files or smaller file sizes. In order to achieve smaller file sizes, the original scan is manipulated by fusing multiple triangular mesh units together to create a more generalized triangular representation of the object surface.

Exported scan using Medit’s i600 intraoral scanner and the tessellated mesh of an STL file.

This process effectively reduces the amount of data in a given file as this manipulation and generalization become more oversimplified. While some clinicians may choose to compress files into a smaller size to decrease the time spent saving data or sending a file for manufacturing, it's important to keep in mind that this also reduces the resolution of scan files and may result in it being hard to identify margin lines for example.

Another drawback of this format is the lack of detailed information it can store, such as the color and texture (a color that varies with location) of the model. Deemed to be quite ‘simplistic’ for this reason, some scanners have the ability to export scans in other file formats such as PLY and OBJ.

Take home message - STL is universally accepted. The main downside is it is not a color file. It is completely monochrome which can make it harder to identify what is tooth and what is gingiva.

PLY (Polygon File Format)

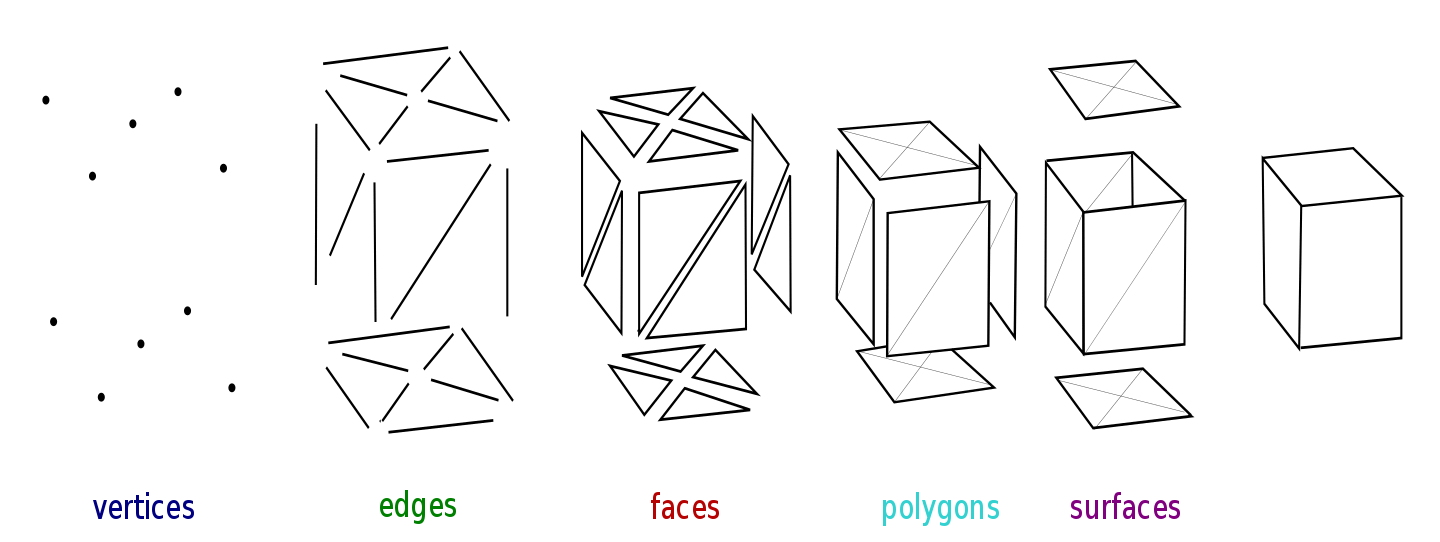

PLY, or Polygon File Format, is a commonly used 3D model format in CAD/CAM dentistry. It stands out from STL files due to its ability to store detailed features like color and texture by using a network of defined triangles. Each triangle is defined by its vertice, face (triangular surfaces that connect the vertices), and edge (connection between a pair of vertices). It is within each vertex that enables PLY files to store this. additional information.

This additional feature is especially beneficial when there’s a need to visually represent the color and texture of teeth or oral tissues in a highly detailed and realistic manner. This could be useful in aesthetic dentistry, where the detailed representation of tooth color and texture can help in designing highly accurate and aesthetically pleasing restorations.

Different elements of polygon mesh modelling, source

In comparison to STL files, PLY files are smaller yet still offer precision and detail, making them more versatile to work with and share. In saying this, PLY files can still be large and may require optimization or compression to reduce the file size if storing data or transferring and exporting to a lab.

Exported scan using Medit’s i600 intraoral scanner and the tessellated mesh of a PLY file.

Not all third-party CAD software support PLY files, but some that do, include 3Shape, exocad, Medit Design, and Meshmixer. Also not not all scanners enable PLY export.

OBJ (Object File Format)

Lastly, OBJ, or Object File Format, is another 3D file format commonly used in CAD/CAM dentistry. Similar to an STL or PLY file, OBJ files are stored and are represented by a 3D model made up of a mesh of triangles.

The only difference an OBJ file has that separates it from an STL and PLY file, is that it also includes a collection of surface normals (direction vectors perpendicular to the faces) like non-uniform rational B-spline (NURBS) surfaces to determine the orientation of an object’s surface for shading and other visual effects. This may be valuable when dealing with complex dental structures or when the case involves intricate restoration work. For instance, in orthodontics, OBJ files might be preferred for their ability to accurately represent the complex curvatures of teeth and oral structures. However in saying that, we have not seen the dental industry really utilise OBJ to its full potential yet.

Like PLY files, OBJ files can contain detailed information like color and texture as well as more complex geometric information such as curves and surfaces. Because of this, it is preferable to use an OBJ file with more complex dental structures to store this type of information. Unlike PLY files, they can be more annoying to work with as they can be quite large.

Note that like PLY, not all scanners enable OBJ export.

Exported scan using Medit’s i600 intraoral scanner and the tessellated mesh of an OBJ file.

Conclusion

STL files export as a monochrome scan, whereas OBJ and PLY files store color and texture that an STL file cannot. Not all intraoral scanners are able to export OBJ and/or PLY files, whereas STL files are universally compatible and widely used across the market as a default option.

There are multiple benefits of using a color file for your lab/technician. So if you're able to, try export PLY and OBJ and check that your lab can accept these files.

It is always best to double-check with the specific software requirements of the dental application or third-party CAD software you are using when it comes to selecting a file format to export your scans.

Despite the difference in the encoded data and information stored between STL, PLY, or OBJ files, the density and accuracy of the 3D mesh remains consistent regardless of the exported file format. They are all accurate file types.

If you have any questions leave them below.