In March 2021, Dentsply Sirona introduced CEREC Tessera - a lithium disilicate block that seemingly competes with Ivoclar Vivadent’s IPS e.max CAD. CEREC Tessera promises to be a “trifecta of speed, strength, and esthetics". We have started using this material in our clinics and so far our experiences have been generally positive. Only time will tell whether this material is all Dentsply Sirona promises it to be (or if it is another Celtra DUO).

Below are our investigations about its processing and aesthetic properties.

What is CEREC Tessera?

Technically speaking, Tessera is what the company likes to call an 'advanced' lithium disilicate. According to the official information by Dentsply Sirona, “rod-shaped crystals provide strength in the same manner as rebar embedded in cement. These crystals increase the density of the material while helping protect against crack propagation.” These blocks also contain virgilite (lithium aluminum silicate), a component of many glass ceramics, which supposedly helps with the aesthetic properties.

Simply put, CEREC Tessera claims to be not only aesthetic but also a high-strength ceramic material. The aesthetics are quite a subjective topic which we will get to later in this article.

The material is sold in boxes of 4 blocks, and it is currently available in these shades:

- HT A2-A3 (no HT A1 or A4)

- MT A1-A3.5 (no A4)

- MT B1

- MT C1

- MT D2

- MT/LT BL2

- No LT shades

As you can see, the selection is quite limited. We assume that Dentsply Sirona plans to eventually introduce a full range of VITA shades and is simply testing the waters with the ‘best seller’ range first.

According to the manufacturer, the biaxial strength of CEREC Tessera is “more than 700 MPa,”. To put it into perspective, Ivoclar Vivadent’s IPS e.max CAD has a biaxial flexural strength of about 500 MPa.

Does stronger mean better, however? It is too soon to tell, and it’s not that simple. More independent studies are necessary to make any judgment. After all, Dentsply Sirona is also the manufacturer of Celtra DUO, a zirconia-reinforced glass-ceramic. This material was said to have a flexural strength of 560 MPa, slightly more than e.max CAD. However, it had a higher than expected fracture rate. A study from 2018 showed the survival rate of Celtra DUO was 76% after only one year, compared to the ‘weaker’ IPS e.max CAD with a 95% survival rate after eight years of monitoring.

Dentsply Sirona seems aware of this and definitely ‘plays it safe’ by indicating CEREC Tessera for single full-coverage crowns, inlays, onlays, and veneers only. On the other hand, Ivoclar Vivadent indicates e.max for short-span bridges up to the second premolar.

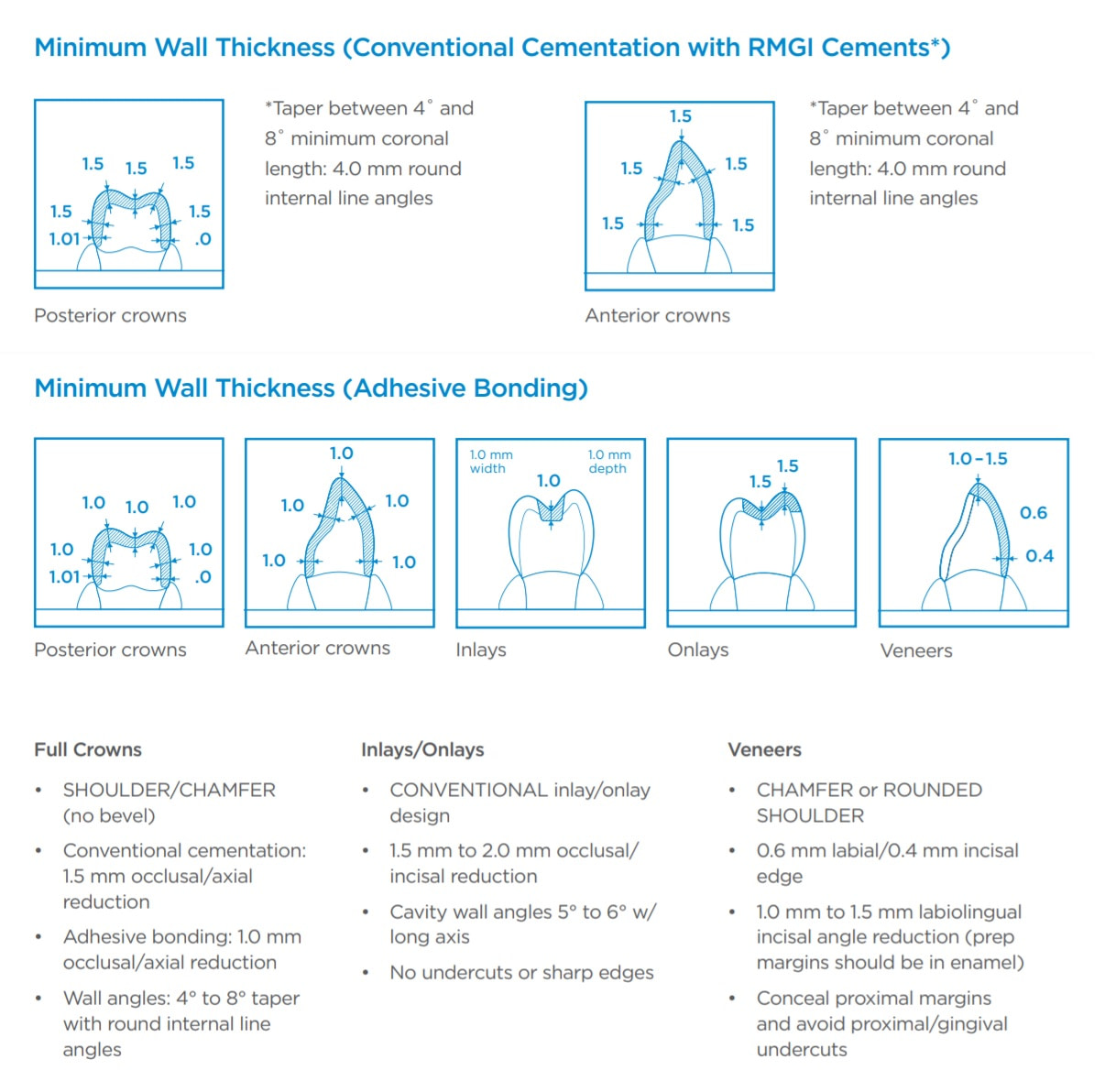

What are the preparation guidelines?

According to the manufacturer’s recommendations, the minimal preparation requirements are similar to any other glass-ceramic material. As with all ceramics, bonding with resin adhesives is recommended, and it allows for an even more conservative preparation. See the official recommended guidelines below.

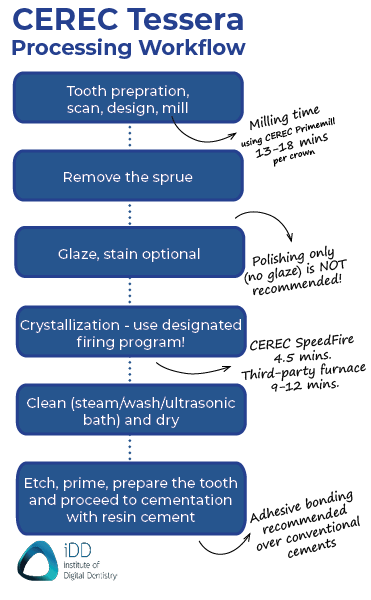

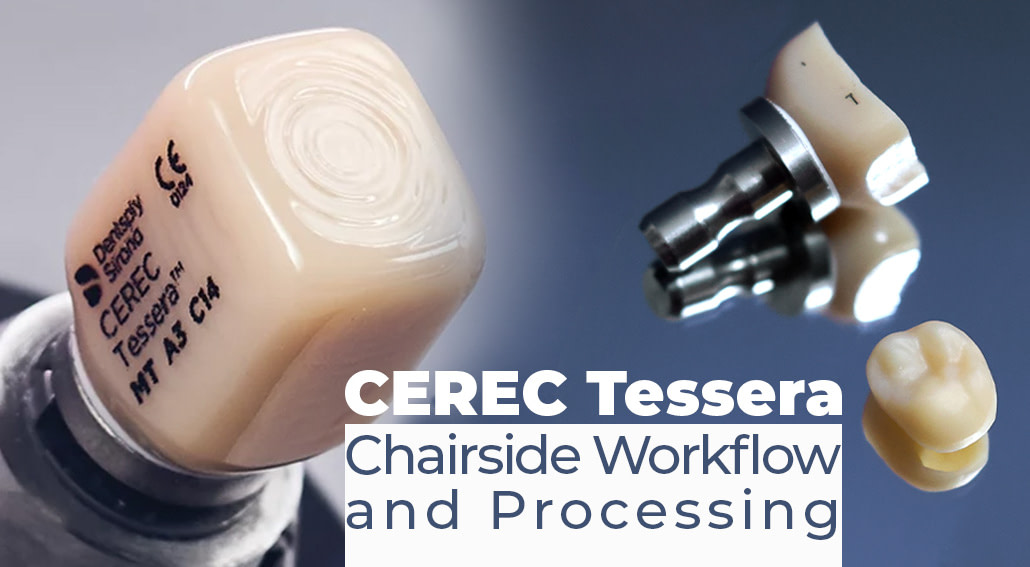

How do you process CEREC Tessera?

The most significant selling point of CEREC Tessera is its fast chairside processing which is undoubtedly true, although it varies depending on the mill and furnace you use (more below).

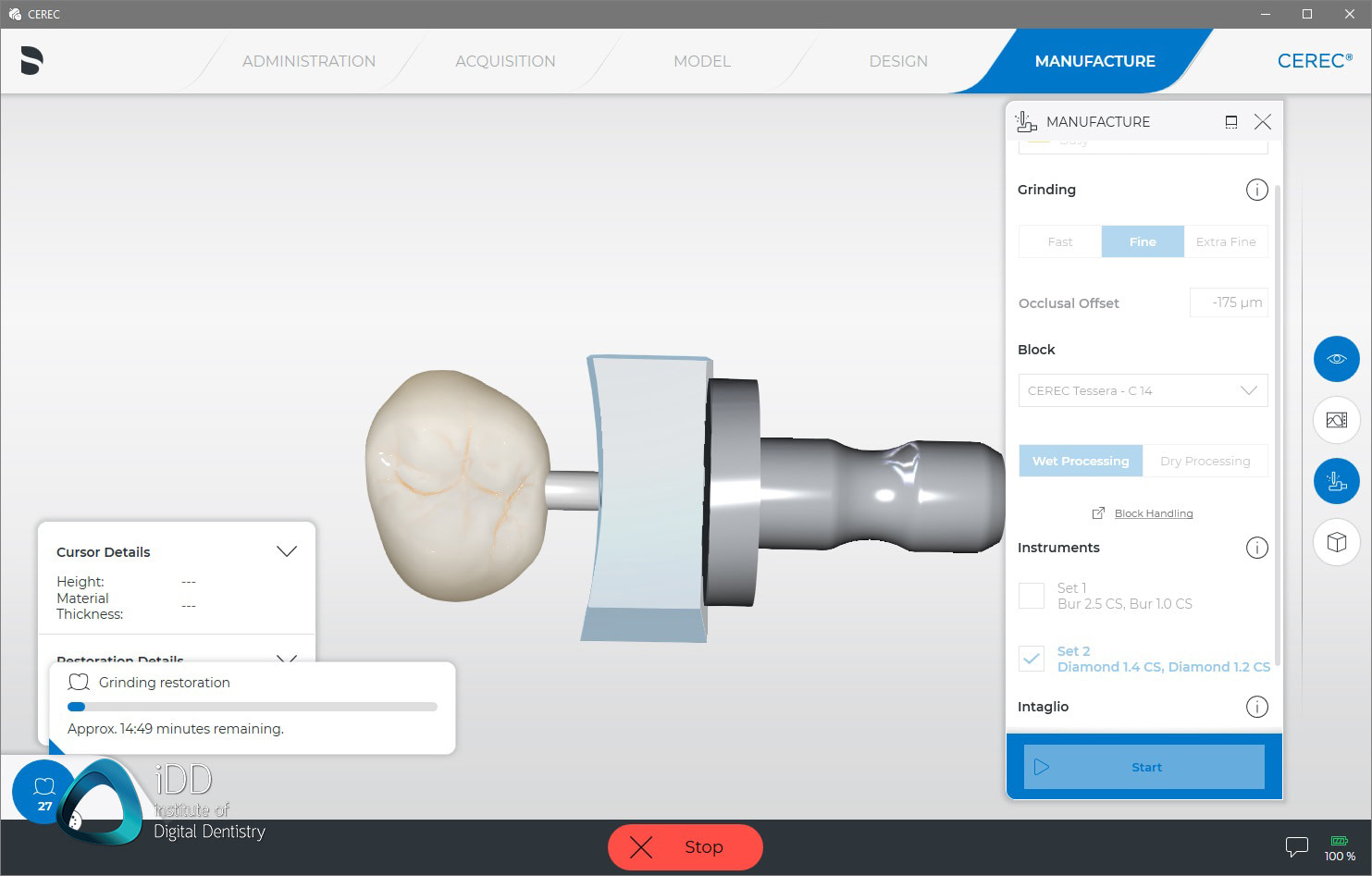

In the CEREC workflow you must first set up the material correctly on your CEREC Primescan – you cannot use the same settings and milling (grinding) strategies that you use for IPS e.max CAD. The good news is that you do not need to change the burs, filter, or coolant.

You can only mill Tessera blocks in CEREC milling machines. We have been advised that there are no options involving third party milling machines to manufacture CEREC Tessera at this stage.

When using a Primemill, a full-coverage crown can be milled from a CEREC Tessera block in 13-16 mins, while an e.max CAD crown takes about 9-12 mins. Unlike e.max CAD, it is NOT recommended to process CEREC Tessera restorations with polishing only - they must always be glazed. As per the official manufacturer’s statement:

“The polishing sequence is not an optional alternative to surface glazing and Matrix Firing. The glazing process is required to achieve maximum strength of CEREC Tessera™ material, but if post-glazing adjustment may be required, it can be consistently polished to a smooth surface with a variety of polishing instruments.”

- Dennis J. Fasbinder

Dentsply Sirona recommends that only their glaze brand is used with this material, either the liquid glaze (Universal stain and glaze liquid, DS Universal Overglaze) or spray glaze (Dentsply Sirona Universal Spray Glaze). They claim that CEREC Tessera is not compatible with IPS e.max CAD Crystal./Glaze Spray, yet Dentsply Sirona Spray Glaze can be used with e.max CAD restorations.

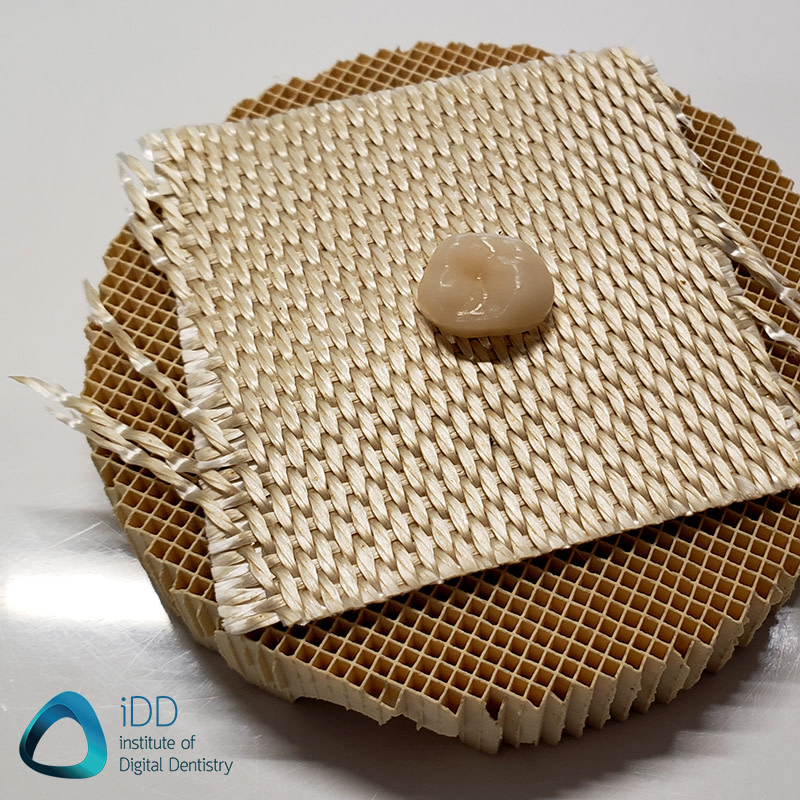

Before crystallization, the manufacturer recommends placing the restorations directly on a special firing pad (pictured below) that goes on the top of their honeycomb firing plate. Alternatively, you can use firing supports (firing pegs/pins), but Dentsply Sirona is adamant that you need to hold it in place using CEREC SpeedPaste only.

Dentsply Sirona Firing Pad shown on the left. The right image shows how to process Tessera using the Firing Pad and Honeycomb Firing Plate

To crystallize Tessera restorations, you can use any third-party firing furnace you use for crystallizing other silicate-based ceramics, and it will take 9-12 minutes. That’s already much quicker than crystallizing e.max in most furnaces. The blazingly fast processing speed that Dentsply Sirona mentions in their marketing campaigns comes when using the CEREC SpeedFire. This is an induction furnace by Dentsply Sirona, and it crystallizes CEREC Tessera restorations in 4.5 minutes. Incredibly fast and must faster than e.max. This is the same furnace that can sinter zirconia crowns within 10-15 mins (which we’ve also been testing).

The CEREC SpeedFire is also unique in regards to the size of its platform - it can only fit up to two restorations simultaneously, which is not necessarily an issue for simple same-day chairside workflows, but can become prolonged when considering a quadrant worth of restorations to process.

If you are considering getting a CEREC SpeedFire while using a third-party mill, we have bad news. You can only use this furnace with a CEREC milling machine (which can only be used with CEREC software). The CEREC milling machine communicates with the furnace and sets up a firing program for the material you chose in the Administration Phase before scanning the case. You then select the case you want to process on the SpeedFire’s display, which usually comes with a few options depending on the material, e.g., firing with/without glaze.

This way, Dentsply Sirona has created a simple, streamlined workflow that leaves very little room for human error. Yet, at the same time, it also effectively closed the whole system for any third-party hardware or materials.

A simplified flowchart of the CEREC Tessera chairside processing workflow.

Testing CEREC Tessera – do the aesthetics suffer from fast processing?

At the Institute of Digital Dentistry, we routinely use the CEREC Primescan and Primemill, and have reviewed this system. In this test, we milled a #27 (left second molar) full-coverage crown from IPS e.max CAD (Ivoclar Vivadent) in 13 mins. The same design took about 17 mins to be milled from a CEREC Tessera block (Dentsply Sirona). This time difference was not surprising as the CEREC Tessera blocks are harder in their pre-crystallized form, and the difference is quite noticeable when removing the sprue manually. We also assume that the wear on the milling burs will be more significant, too.

Test crown #27. A real case scanned and designed using CEREC Primescan, milled with CEREC Primemill. Both blocks are similar in size. The only difference might be the quality of printed labels on the CEREC Tessera blocks – they are easy to wipe off with bare hands, which might lead to confusion if mishandled.

We then tried using both a third-party firing furnace, the Programat CS2 by Ivoclar Vivadent, and the CEREC SpeedFire, an induction furnace by Dentsply Sirona.

First, we crystallized the crowns using Programat CS2 without any glaze because we wanted to eliminate as many variables that might affect the outcome. As mentioned above, Dentsply Sirona does not recommend skipping the glaze step as it will prevent the material from ‘achieving maximum strength.’ Since this crown was not going to place in a patient’s mouth, and we were interested in the shade and translucency of CEREC Tessera, we decided to skip this step for this test.

The first test batch was milled from IPS e.max CAD and CEREC Tessera in the shade MT A3. The Tessera crown appeared to be a shade darker than the e.max crown. Glassy ceramics generally tend to be darker before cooling down completely, but CEREC Tessera seems to be taking an extra long time to ‘settle’.

Admittedly, factors may have affected our observation but that being said, here you can see a picture of these crowns side by side a month after milling and crystallizing in Programat CS2:

The same crown design milled from IPS e.max CAD MT A3 (left) and CEREC Tessera MT A3 (right). Both crystallized in Programat CS2 without glaze. Not polished or otherwise post-processed. The CEREC Tessera crown seems to have a more matte surface compared to the e.max crown.

When we showed this to the company, Dentsply Sirona representatives said that the shade difference is due to us not sticking to the prescribed workflow: they told us that we must not skip the glazing step and should use the CEREC SpeedFire and their honeycomb plate with a firing pad. This would fix this issue.

Therefore, we processed the second test batch with the recommended Dentsply Sirona spray glaze and crystallized it in CEREC SpeedFire on a DS firing pad, giving them the benefit of the doubt. As you can see below, CEREC Tessera again looked darker than IPS e.max CAD of the same shade (MT A3), and the difference appears to be even more evident in this picture.

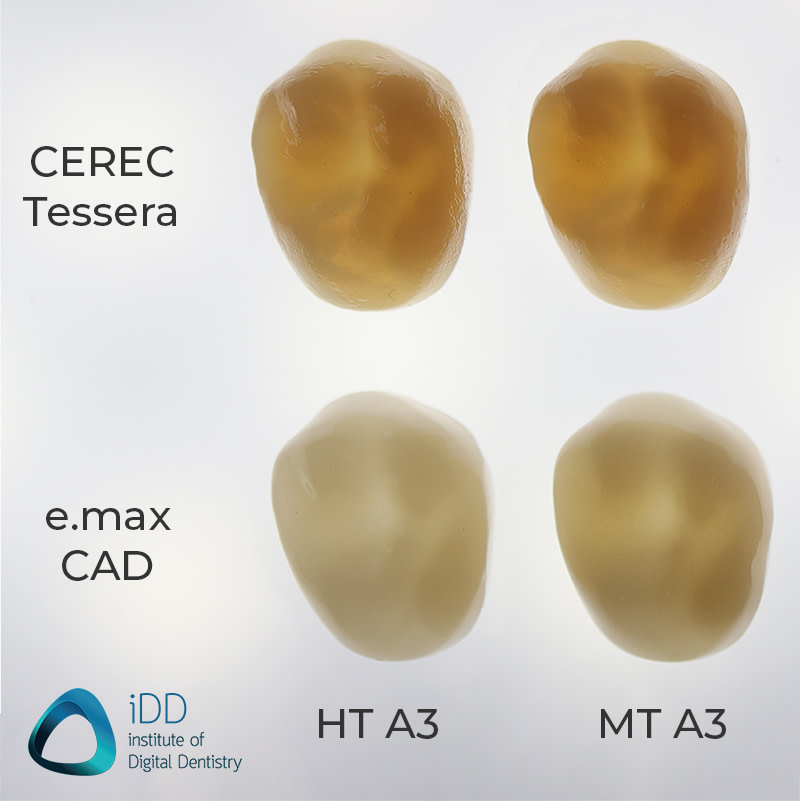

IPS e.max CAD (left) compared to CEREC Tessera (right), same shade MT A3. Upper row, unglazed crowns crystallized in Programat CS. Bottom row crowns were glazed and crystallized in CEREC SpeedFire.

Sticking to the same workflow (spray glaze + SpeedFire + firing pad), we then milled the crowns from the HT A3 blocks in both materials. The Tessera crowns looked very similar despite being different levels of translucency.

The same crown design milled from CEREC Tessera blocks in HT A3 (left) and MT A3 (right).

Lastly, we compared the translucency of the HT and MT crowns, both in e.max and Tessera. The crown milled from IPS e.max CAD in HT appears to be more translucent than the crown milled from MT block, just as expected. When comparing the CEREC Tessera crowns, the difference between HT and MT is not as striking.

Translucency comparison of CEREC Tessera (top) and IPS e.max CAD (bottom).

The same design milled from HT A3 (left) and MT A3 (right) blocks.

The CEREC Tessera crowns were all crystallized in 4.5 mins each but curiously enough, the e.max CAD crowns took up to 36 minutes (!!!) to crystallize in the CEREC Speedfire. We do not know whether it’s due to technical reasons or the Dentsply Sirona furnace not being optimized for e.max crowns.

Generally speaking, longer processing times usually result in better aesthetic properties when crystallizing glassy ceramics or sintering zirconia. Faster programs tend to reduce a materials’ translucency, making the restorations more opaque, and some studies have shown that it can also decrease the materials’ strength. It makes us wonder whether that’s what's happening to CEREC Tessera, and the ultra-short firing cycle may not allow the translucent properties to develop adequately.

Summary

CEREC Tessera is a new advanced lithium disilicate material developed by Dentsply Sirona that has been integrated into their streamlined, chairside CEREC workflow. It can be milled in any CEREC milling machine and crystallized in under 12 minutes using a third-party furnace or in 4.5 minutes using the CEREC SpeedFire, an induction furnace by Dentsply Sirona. This is one of the fastest lithium disilicate workflows.

More studies are necessary to assess the physical properties accurately, and only in-vivo observations will reveal the actual survival rate of CEREC Tessera restorations. In this article, we reviewed the processing, chairside workflow, and aesthetic properties of CEREC Tessera when compared to IPS e.max CAD (Ivoclar Vivadent) - arguably the biggest rival of this new chairside material.

CEREC Tessera is currently available in a limited shade range (VITA) and mainly in MT and HT levels of translucency and no LT shades yet. The difference between MT and LT translucency seems minimal. Additionally, CEREC Tessera restorations appear darker than IPS e.max CAD crowns of the same VITA shade and darker than the VITA Shade Guide itself.

With this being said, most dentists should not get discouraged by the limited shade range, lesser translucency, or slightly darker outcomes as long as the final shades are predictable. This material does provide one major advantage, and that is it speeds up the same-day workflow considerably. Time will tell how it performs in the mouth.

Can i have this article as a pdf please

Thanks for efforts

Dear Yasmin,

Unfortunately, only our scanner reviews are available for PDF download.

I own a OmniCam (upgraded software) with an MCXL and Programat CS2

One of the reps recommended the new Tessera block to me as it is harder in property. I mainly use CeltraDuo.

Does this new block take longer to grind with the MCXL? Does it have the same Programat CS2 furnace protocol as CeltraDuo?

Correct me if I'm wrong, but if we cook up CeltraDuo, it's hardness increases but not sure if as hard as Tessera.

At least with CeltraDuo you can polish (although, not sure if that is recommended either). Thoughts?

Hey Jacqueline,

I would recommend Tessera over Celtra Duo. In many ways, it is the successor product.

Great question about timings – they are pretty similar. I have not personally timed to the second both but you shouldn’t find a large jump in milling time – let me know!

The furnace protocol is different to celtra duo. Get those details from your sales rep and ensure the right temps are used.

The reason the company is pushing Tessera is that Celtra Duo actually has a higher than acceptable fracture rate over the years. Dr Gordon Christensen has published research articles that show Celtra had 73% fracture survival during 1 service year.

So the company is shifting away from Celtra and recommending Tessera. I personally just use e.max as my silicate ceramic of choice.

I would not recommend polishing and placing celtra duo personally. Always fire. But Tessera is said to be the flagship ceramic of DentSply Sirona – so I try it!

Hope that helps.