The dental 3D printing market has an interesting problem.

On one end, you have entry-level printers that are affordable but often require trial and error to achieve consistent results. They are not really fit for purpose for dental use. On the other end, premium systems deliver reliability and precision but come with price tags that put them out of reach for many practices. What about the space in between?

Phrozen is making a push to try to fill that gap with their latest releases: the Sonic CS+ printer and CURE+ post-curing unit.

The company is positioning these as accessible high-end solutions, bringing some features typically found in more expensive dental printers to a much more approachable price point. Phrozen printers have been utilized in dental printing for some time as a cost-effective option, but required a lot of tinkering with print profiles. However, what is notable now is that the company is focusing on dental applications and aims to offer a comprehensive, specific dental solution. Rather than just having clinicians and labs buy the printers from Amazon and tinker with them to get them to work.

Here at iDD, we have been testing the Phrozen CS+ and CURE+ for the past few months, and we will soon publish a comprehensive review of both the Sonic CS+ and the CURE+. However, before we dive into the evaluation, let's go over what Phrozen is promising with these releases.

The Sonic CS+: Chairside Printing

The Sonic CS+ is designed for same-day chairside workflows. Phrozen claims you can fabricate and deliver dental appliances to patients in under 90 minutes.

What's interesting about the CS+ is its feature set:

- 385 nm UV-A LCD technology with 22µm XY resolution - The shorter wavelength is becoming popular in dental 3D printing and is expected to deliver more precise depth layer curing, particularly important when working with highly viscous resins. However, 385 nm light is known to accelerate the degradation of LCDs. Phrozen claims their LCD is optimized for a screen lifespan of 600,000-1.5 million layers. LCDs are always the point of failure for these types of printers.

- Dual plate and vat system - The CS+ comes with two build plate sizes, each with its own matching resin vat. The Mini Plate is designed for single restorations, such as crowns and bridges (Phrozen claims 15-minute print times), while the Standard Plate increases build volume for higher daily throughput. Nice to see multiple plate options here.

- Pre-validated resin settings - Out of the box, the CS+ includes validated profiles for Pac-Dent, Saremco, Dreve, and Keystone resins. This is a big positive for dental printing. No more tinkering with profiles.

- Open material system - Phrozen allows you to use third-party materials.

- Dual heating system - Temperature control is crucial for achieving consistent prints, particularly with temperature-sensitive dental resins. The dual heating system should help maintain stable conditions throughout the print process.

The CS+ is clearly targeting the chairside market where speed and reliability matter most. However, a broader question arises: Is the chairside 3D printing workflow truly ready for mainstream adoption? You need the printer, post-processing equipment, workflow integration, and clinical time to make it work. The CS+ might offer a nice option for the printer part of that equation, but it's just one piece of a larger puzzle.

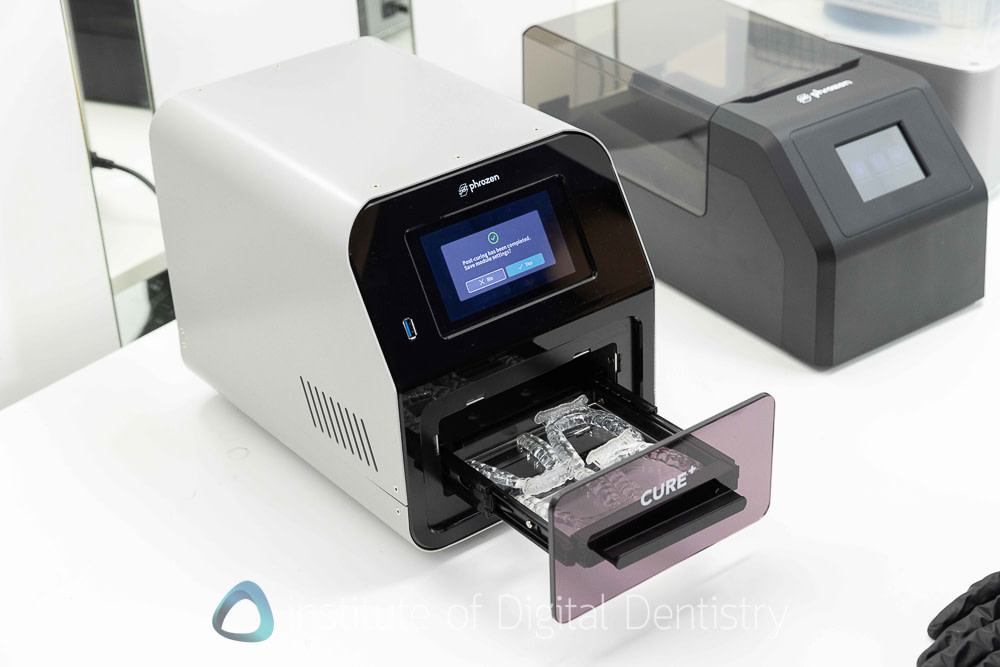

The CURE+: Post-Processing Actually Matters

Post-processing is often treated as an afterthought in dental 3D printing discussions, but it's absolutely critical for achieving proper mechanical properties and biocompatibility.

The CURE+ is Phrozen's answer to this step. Key features include:

- Broad wavelength coverage (365, 385, and 405 nm) - This multi-wavelength approach should ensure compatibility with various resin chemistries. Different resins have different photoinitiators that respond optimally to specific wavelengths, so having this range is nice.

- Flash curing technology - Designed to deliver powerful curing without the risk of overcuring or causing brittleness. This is particularly important for dental applications, where mechanical properties must be precisely tailored. Too little curing compromises both strength and biocompatibility. Too much and you risk brittleness or discoloration.

- Controlled heating at 60°C - Heat during post-curing increases polymer chain mobility, which theoretically creates tighter bonds and better mechanical properties. This is well-established in polymer science, but the keyword is 'controlled.' Temperature uniformity throughout the curing chamber matters.

- Preset curing profiles - Similar to the printer's validated resin settings, the CURE+ comes with preset profiles designed to meet biocompatibility standards when using third-party resins.

What Else Is Coming

Beyond the CS+ and CURE+, Phrozen unveiled several other products that round out their dental 3D printing ecosystem. While these aren't the focus of our review, they're worth mentioning:

Sonic LS+ - For labs focused on batch production, the LS+ combines a large 9.1" print surface with the same 385nm UV-A LCD technology. Phrozen claims it can handle up to 20 full-arch models or 35 occlusal splints per batch. The promise is being able to print 8 restorative models flat in 36 minutes or 20 aligner models in 1.5 hours. The company says the LS+ will be available for purchase in November 2025.

Heat & Mix - A hands-free resin mixer that uses multidirectional rolling and heat to evenly disperse highly filled ceramic resins.

TRIM+ - An automated aligner trimmer that claims to trim 1-1.5 minutes per aligner, with automatic trim line generation. For practices or labs that use thermoformed clear aligners, this could be a significant time-saver.

The devil is in the details, though - trim quality and edge smoothness will determine whether this is genuinely useful or just faster at creating work that still requires hand-finishing anyway.

V-CURE - A vacuum-based curing unit that eliminates oxygen exposure, removing the need for glycerin baths or nitrogen setups. It is expected to launch in Q2 2026.

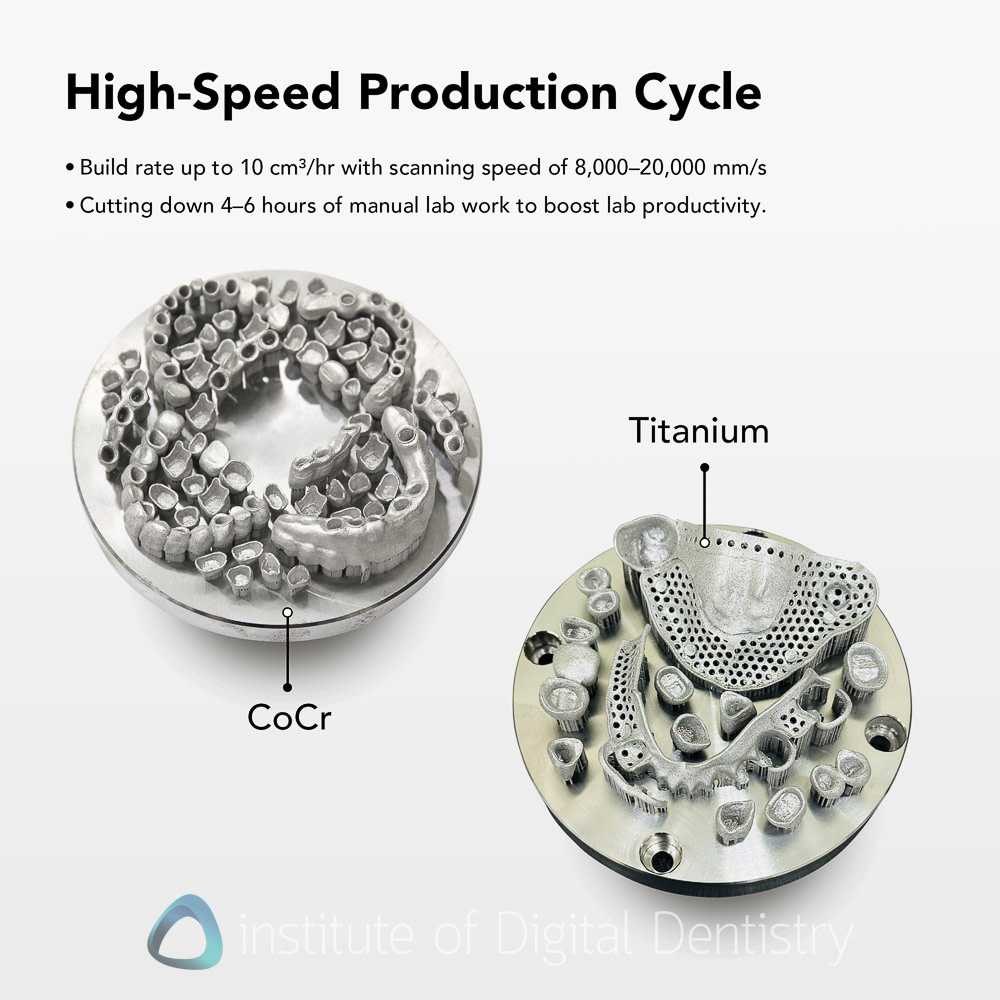

FORGE Metal Printer (Q2 2026) - This is Phrozen's entry into metal 3D printing, featuring a US-made 300W IPG laser and a 100 cm³/hr build rate. Fascinating to see this development. Could metal printing finally be more accessible?

This printer is designed for titanium and CoCr appliances at 50 µm layer height, with claims of reducing manual work by 4-6 hours. Metal printing for dental labs remains relatively niche due to its cost and complexity, but if Phrozen can make it more accessible, this could be a significant breakthrough.

The Price Point - Accessible, But At What Cost?

The complete package - CS+, WASH+, CURE+, and Heat & Mix - starts at $6,200 USD, with the CS+ alone priced at RRP $4,000.

In the context of the dental 3D printing market, this is aggressive pricing. Phrozen is clearly positioning this as the value proposition in the accessible high-end segment. For reference, this is in the price range of Formlabs and Shining 3D printers but cheaper than Asiga, Sprintray, Nextdent etc.

The other consideration is the total cost of ownership. The upfront price is just one part of the equation. What are the LCD replacement costs associated with 385 nm technology? Resin consumption? Maintenance requirements? These are the questions we'll be exploring in our detailed review.

The critical consideration with economic printer options is 2 things, in my opinion:

1) How often do I need to replace the LCD's in the printer, which are often the part that expires fastest

2) What resin options do I have access to, and how reliable are they to print?

What This Means for the Market

Phrozen's strategy with this release is clear: democratize access to higher-end dental 3D printing features. If they can deliver on the promises, it may put pressure on established players who have been charging premium prices. Can they shake the perception of being a 'lower quality' option, however? Whether this is true or not, many people feel this way about economic printers.

For dental practices and labs, this could represent a genuine opportunity to adopt chairside or in-house 3D printing without the traditional financial barriers. The pre-validated workflows and open material system address two of the biggest adoption hurdles: ease of use and flexibility. Especially if you just want to print models, splints, and surgical guides... papers have proven that basically all mainstream 3D printers work and can achieve dimensionally accurate results.

Specifications and marketing claims are one thing. Consistent, reliable performance day after day is something else entirely. We're not interested in regurgitating press releases. We want to know: Does the CS+ actually deliver consistent prints across different materials and environmental conditions? Do those validated profiles really work, or will users still need to undergo significant trial and error? Is the CURE+ genuinely effective at achieving proper post-cure, or is it just a UV box? Can the complete workflow reliably support same-day chairside dentistry?

Final Thoughts and What to Expect

Phrozen is making bold claims with the CS+ and CURE+. The feature set looks impressive, the pricing is competitive, and the open ecosystem approach is nice. I'm genuinely interested to see how these products perform in extended testing.

If Phrozen has truly managed to bring these features to an accessible price point without significant compromises, that's exciting for the entire digital dentistry community. If trade-offs or limitations become apparent over time, we need to understand them so practitioners can make informed decisions.

In the meantime, if you're interested in learning more about the CS+ and CURE+ or Phrozen's complete product lineup, you can visit their website at https://phrozen3d.net/KIzyd.

What are your thoughts on Phrozen's approach to accessible high-end dental 3D printing? Are you currently using 3D printing in your practice or lab? What features matter most to you when evaluating these systems?

Drop your questions and experiences in the comments below. Your real-world perspectives help inform our testing priorities and make our reviews more valuable for everyone.

Stay tuned for our comprehensive review. We'll report back with our findings, both good and bad.